Soilless potassium formate water-based drilling fluid for drilling shale

A potassium formate water-based drilling fluid technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of heavy maintenance and treatment workload, insufficient lubrication and anti-seize ability, poor stability of well wall, etc., and achieve cost Low, little impact on rheology, little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

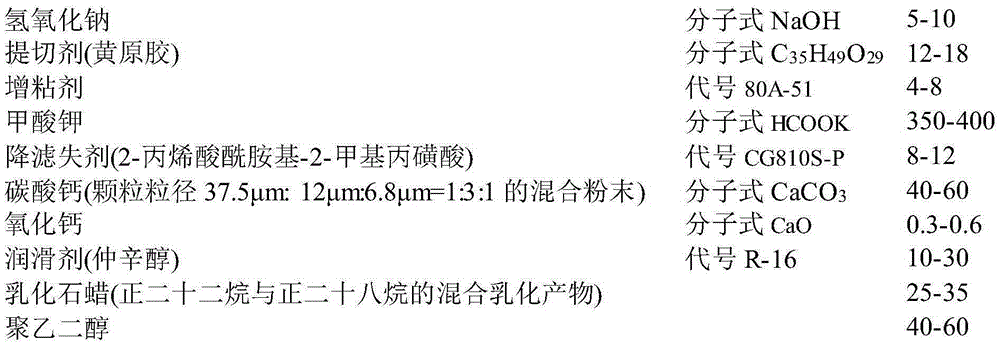

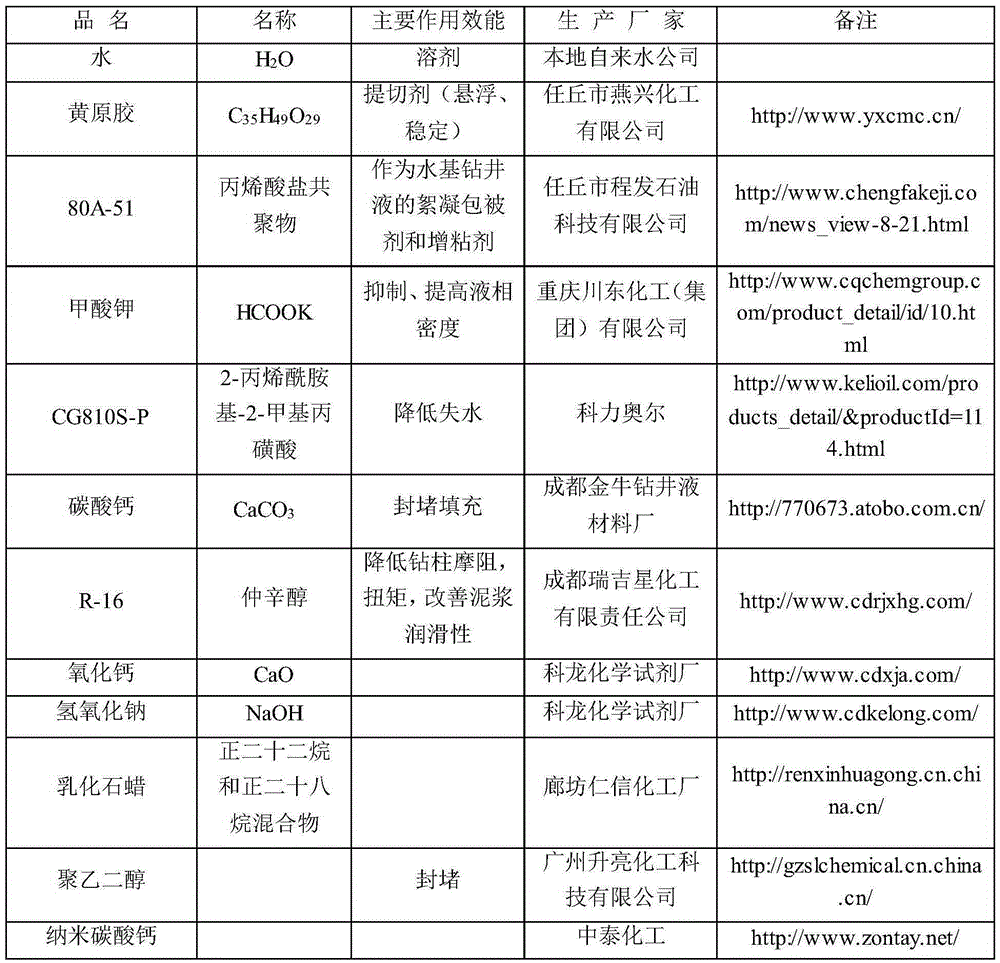

[0015] Embodiment 1: a kind of preparation method of soilless potassium formate water-based drilling fluid for drilling into shale is:

[0016] First measure 1000 grams of tap water, add 15 grams of xanthan gum and stir for 6 minutes under electric stirring at a low speed of 500r / min, then add 5 grams of tackifier 80A-51 and stir for 5 minutes, add 380 grams of potassium formate and stir for 10 minutes, add 10 Add 0.5 g of calcium oxide and stir for 5 minutes, add 50 g of calcium carbonate (particle size: 37.5 μm: 12 μm: 6.8 μm = 1:3:1 mixed powder) and stir for 15 Minutes, add 20 grams of lubricant R-16 and stir for 5 minutes, add 50 grams of polyethylene glycol and stir for 5 minutes, add 30 grams of emulsified paraffin and stir for 10 minutes, add 10 grams of nano calcium carbonate (particle size is 80-200nm) in Stir for 5 minutes at 8000r / min, prepare a lye with a mass concentration of 40% with NaOH, adjust the pH of the system to 8.5, and stir for 1 hour to obtain a densi...

Embodiment 2

[0017] Example 2: Inhibition Evaluation

[0018] The rolling recovery rate of the drilling fluid system of the present invention was measured by using the XGRL-2 type roller heating furnace.

[0019] Table 2 Experimental results of rolling recovery rate of soil-free potassium formate water-based drilling fluid system

[0020] Drilling Fluid Formula

Experimental conditions

Recovery rate(%)

Clear water + 50g red bed soil

105℃ / 16h

5.64

11.28

Low-density water-based drilling fluid system + 50g red bed soil

105℃ / 16h

47.92

95.84

[0021] Note: 1) The red layer soil is Sichuan red layer soil debris, and the shale outcrop is Chang 7 shale outcrop, all of which are 6-10 mesh, and the recovery rate is over 40 mesh; 2) The results in the table are all 2 times The mean of the experimental data.

[0022] Table 3 Experimental results of linear expansion of water-based drilling fluid system

[0023]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com