Horizontal well cement paste

A well water and mud technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of not being able to maintain the integrity of the cement sheath, not being able to disperse the cement particles uniformly, and poor stability of the cement slurry system. Elastoplasticity, small brittleness coefficient, and high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A horizontal well cement slurry shown includes the following components: cement + toughening agent GZR + GFC expansion agent + GH retarder, the weight percentage of each component is, toughening agent GZR0.5%-2.5 %, GFC expansion agent 1%-3%, GH retarder 0.04%-0.08%, and the rest is cement. It also includes GSJ fluid loss reducer and USZ dispersant, the GSJ fluid loss reducer accounts for 0.2%-0.4% by weight, and the USZ dispersant accounts for 0.04%-0.08% by weight. Using this formula, make the following performance evaluation of this cement slurry

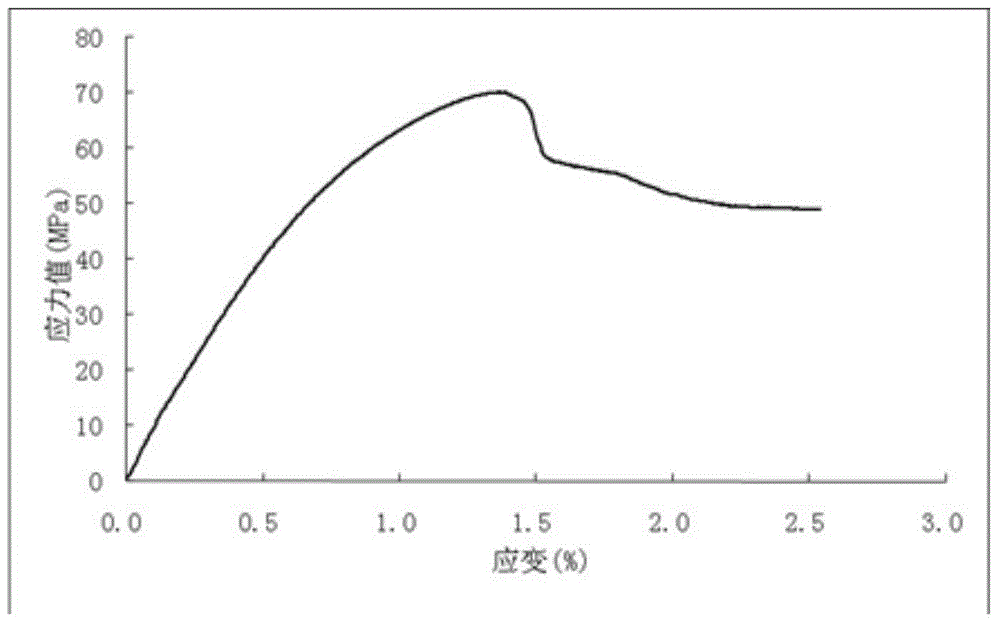

[0035] 1. Toughness evaluation:

[0036] Table 1 Routine performance evaluation of ductile anti-channeling cement slurry system:

[0037]

[0038] 2. Evaluation of expansion performance

[0039] Table 2. Expansion test at different temperatures with different additions of GFC expansion agent

[0040]

[0041] It can be seen from Table 2 that the lattice expansion material GFC shows a certain expansion effect at d...

Embodiment 2

[0043] On the basis of embodiment 1, described GZR toughening agent is made up of elastic particle material, anti-fracture material and anti-seepage material, and described elastic particle material, anti-fracture material and anti-seepage material are according to 20:1.5: It is formed by mixing in a ratio of 1.5. The elastic granular material is thermoplastic elastomer TPR granular material from Dongguan Jiejia Plastic Technology Co., Ltd., the anti-fracture material is waste rubber particles, and the anti-seepage material is polyethylene;

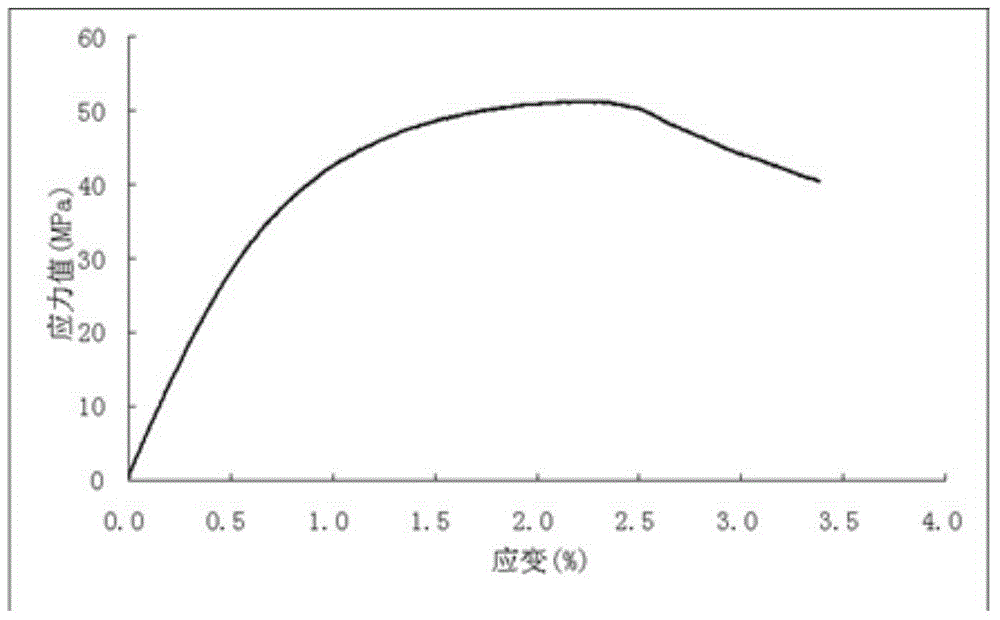

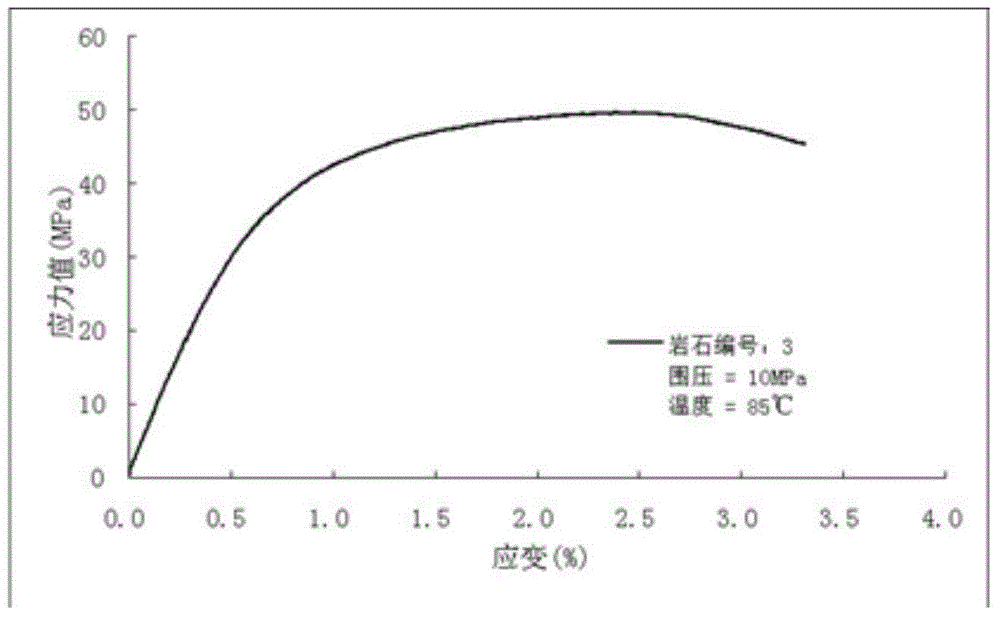

[0044] The following is the performance evaluation of a toughening material, the Young's modulus Poisson's ratio of cement stone under different additions

[0045] Determine the toughening material GZR-1 as the main material of the tough cement slurry, change its addition amount in the cement, and the measured cement stone properties are shown in the following table:

[0046] Table 3 Performance test of cement stone under different dosage...

Embodiment 3

[0076] The expansion agent is composed of 1.2% sodium chloride, 1.5% sodium thiosulfate, 0.3% pull-off powder BX, 0.4% water reducing agent JN0.4%, 0.8% ammonium chloride, and 0.005% aluminum powder according to the weight percentage of the following ingredients: %, iron powder 95%, sodium chloride is industrial salt; sodium thiosulfate; used as an alkaline additive in this agent, pull open powder BX hair dye, used as a dispersant in this agent; water reducer JN also known as Sodium methylnaphthalene sulfonate formaldehyde condensate, brown powder; easily soluble in water, stable chemical properties, non-flammable, non-toxic. Used as a cement additive, it has a strong dispersing effect on cement particles, expands the contact area between cement and water, promotes hydration reaction, reduces water consumption, and improves the strength, compactness and impermeability of concrete. Choose industrial products. Ammonium Chloride Dairy Equipment Cleaner. This agent is used as a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com