Chlorine-free fluid migration prevention early strength agent for oil well cement, and preparation method and application thereof

A technology of oil well cement and early strength agent, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of perforation casing damage, high Clˉ content in underground drinking water sources, shortening the service life of casing, etc. Effects of early compressive strength and cementitious strength, prolonging single well production life and shortening thickening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

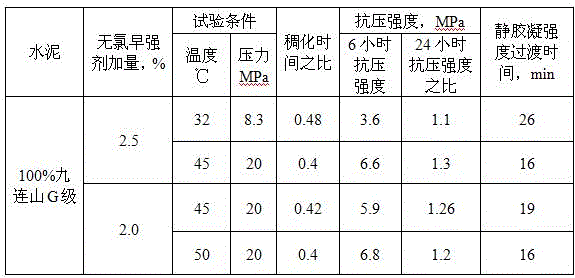

Examples

Embodiment 1

[0021] This embodiment provides a chlorine-free anti-channeling early strength agent for oil well cement, which is composed of the following mass percentages: coagulation accelerator 33-48%, expansion agent 20-25%, organic early strength agent 1-2%, The balance is filler.

[0022] The principle of the invention: the coagulant can accelerate the hydration process, thereby accelerating the hardening and coagulation of the cement slurry, and the expansion agent expands in volume when the cement sets and hardens, compensating for shrinkage and tensioning the steel bars to generate prestress and fully filling the cement gap The organic early strength agent mainly accelerates the low-temperature hydration coagulation speed of the cement slurry, and improves the early strength of the cement stone. The filler can fill the pores between the cement particles and form a gel with the hydration product. Effectively eliminate the incompatibility between cement materials and formation mud ca...

Embodiment 2

[0024] On the basis of Example 1, this example provides a chlorine-free anti-channeling early-strength agent for oil well cement, which is composed of the following mass percentages: coagulant 33%, expansion agent 20%, organic early-strength agent 1 %, the balance is filler.

[0025] Preparation process: Add sodium silicate, expansion agent, and organic early strength agent into the mixing tank according to the formula percentage, stir for 8-10 minutes, and let it stand for 30-40 minutes; then add the formula amount of calcium formate, sodium aluminate and filling material, and stirred for 10-15 minutes to prepare the chlorine-free anti-channeling early strength agent for oil well cement.

[0026] In this example, the coagulant is composed of 5% calcium formate, 8% sodium aluminate, and 20% sodium silicate, the expansion agent is barite, the organic early strength agent is ethylene glycol, and the filler is carbonic acid. calcium.

[0027] Calcium formate, sodium aluminate a...

Embodiment 3

[0029] On the basis of Example 1, this example provides a chlorine-free anti-channeling early-strength agent for oil well cement, which is composed of the following mass percentages: coagulation accelerator 44%, expansion agent 22%, organic early-strength agent 1.5% %, the balance is filler.

[0030] Preparation process: Add sodium silicate, expansion agent, and organic early strength agent into the mixing tank according to the formula percentage, stir for 8-10 minutes, and let it stand for 30-40 minutes (make the water contained in calcium oxide and triethanolamine fully exothermic and cool After that); then add the formula amount of calcium formate, sodium aluminate and filler in turn, and stir for 10-15 minutes to obtain the chlorine-free anti-channeling early strength agent for oil well cement. The obtained oil well cement chlorine-free anti-channeling early strength agent has a density of 2.36g / cm 3 .

[0031] In this example, the coagulant is composed of 8% calcium for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com