Liquid toughening leakage-blocking agent for well cementation

A kind of lost circulation agent and liquid technology, applied in the field of lost circulation agent, can solve the problems of not playing the role of leakage and leakage prevention, unable to stir evenly, increasing cementing risk, etc., to prevent gas channeling and oil channeling, and reduce viscosity , the effect of increasing the impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

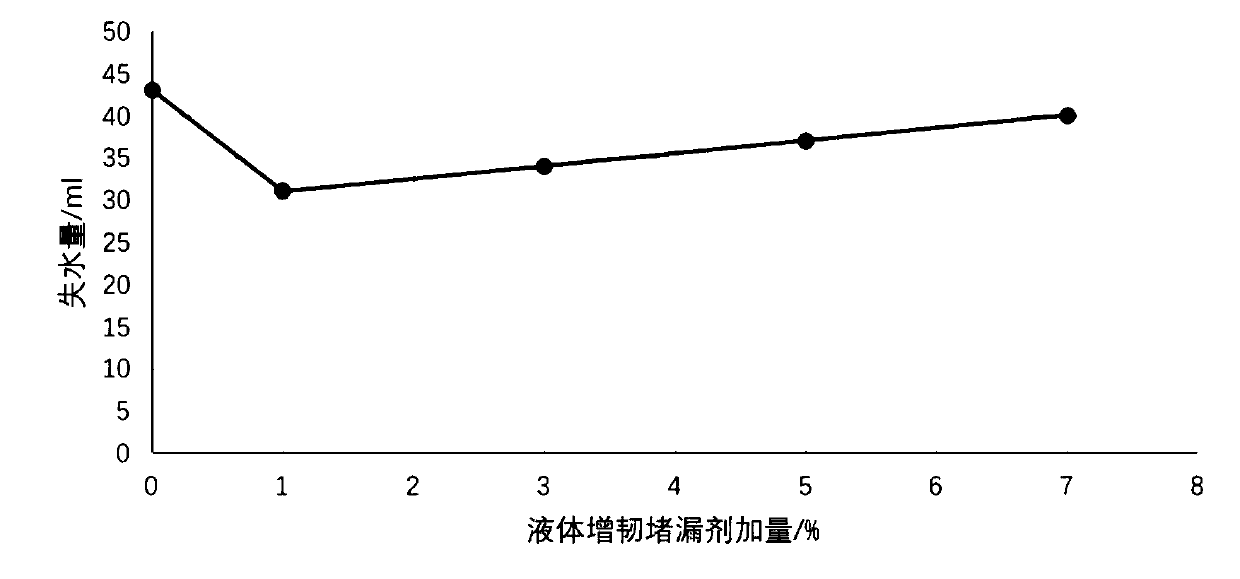

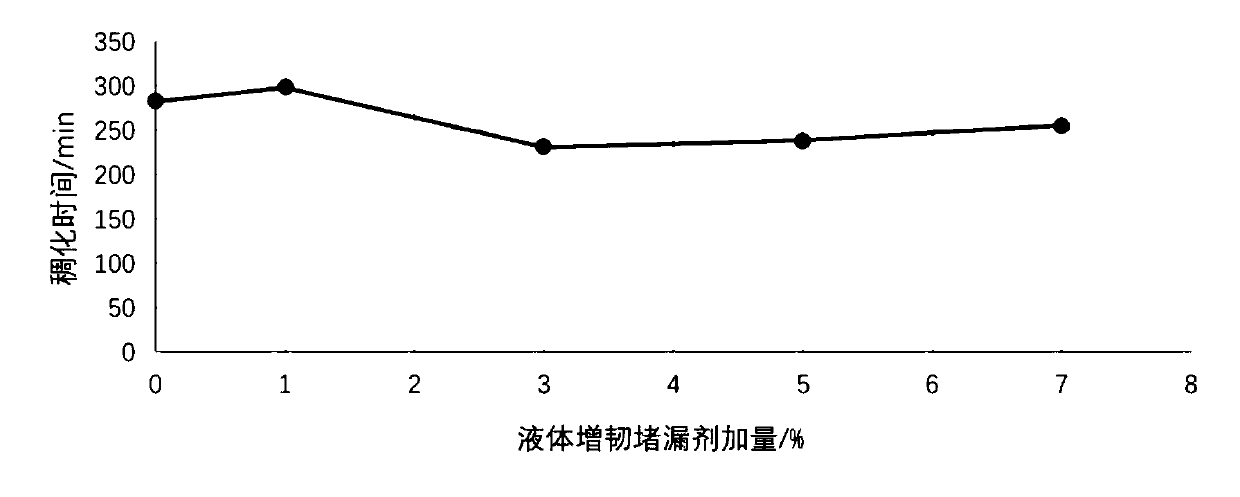

[0016] Such as figure 1 As shown, the liquid toughened lost circulation agent for well cementing of the present invention includes a new type of fiber material.

[0017] A liquid toughening plugging agent for cementing, including a new fiber material, the new fiber material is formed by stacking flake graphite microcrystalline organic fibers along the axial direction of the fiber, and is a microcrystalline graphite material obtained by carbonization and graphitization . The carbon content of the new fiber material is not less than 95%. After the liquid toughening plugging agent is prepared, it is added to the stirred cement slurry and stirred.

[0018] The liquid toughening plugging agent is a new type of fiber materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com