Multifunctional safety protection shoe

A safety protection and multi-functional technology, applied in the field of safety shoes engineering, can solve the problems of weak grip, no electrical insulation function, no waterproof function, etc., and achieve the effect of reasonable design, compact structure and obvious warning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

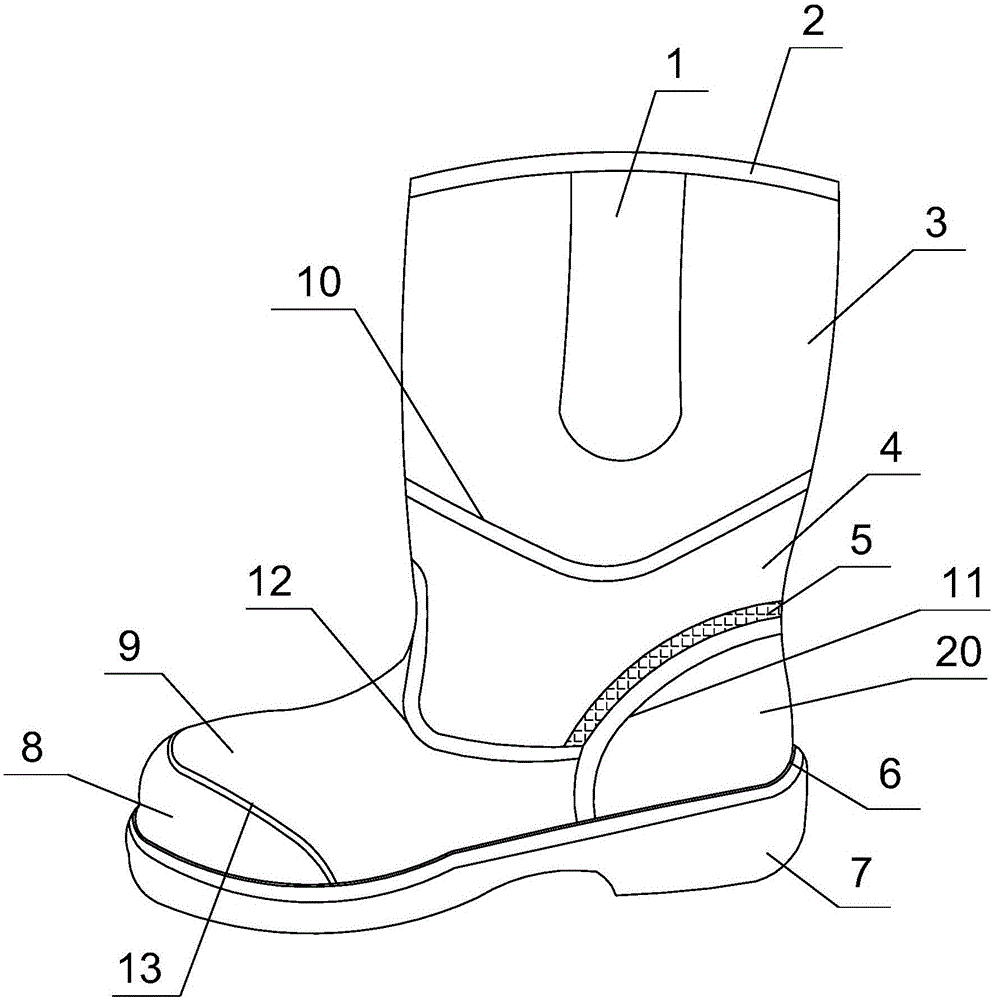

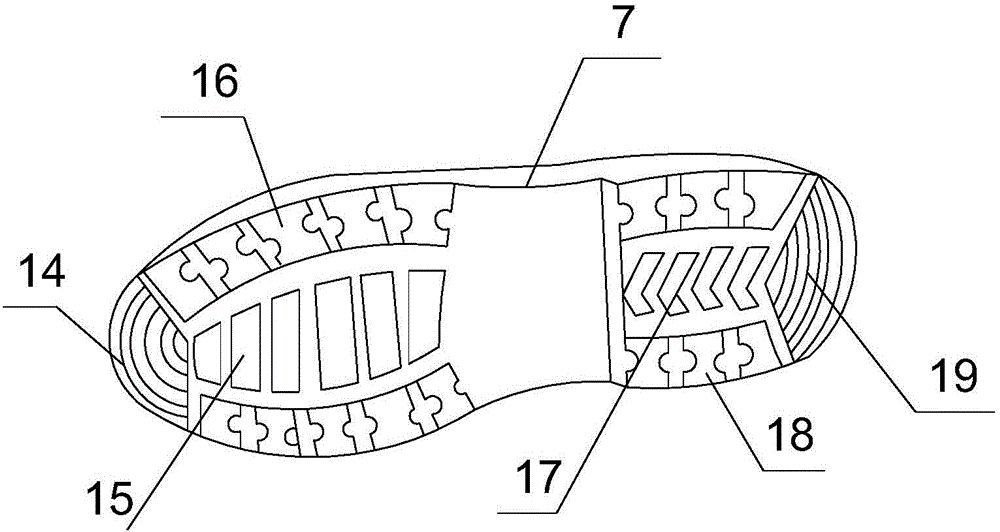

[0023] see figure 1 , a multifunctional safety protective shoe, comprising a shoe upper body, a midsole 6 and a shoe sole 7; the shoe upper body includes an upper shoe upper 3, a middle shoe upper 4, an anti-collision toe 8, a front shoe 9, and a shoe rear shoe 20; The upper end of the upper upper 3 is provided with a shoe mouth, and the upper end of the upper shoe 3 is stitched with a wrapping 2, and the upper end of the upper upper 3 is stitched with hanging ears 1 on the front and rear sides, and the lower edge of the upper upper 3 is connected with the upper edge of the upper upper 4 by sewing to form a The first connecting part 10, the left lower edge of the middle upper of a shoe 4 and the upper right edge of the upper right of the shoe upper 9 are stitched together to form the third connecting part 12, the lower right edge of the middle uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com