Multifunctional reaction kettle for reservoir response and sand production simulation in hydrate exploitation

A hydrate and reactor technology, applied in chemical/physical processes, analysis of suspensions and porous materials, chemical/physical/physical chemical processes, etc. Security, stability and efficiency issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

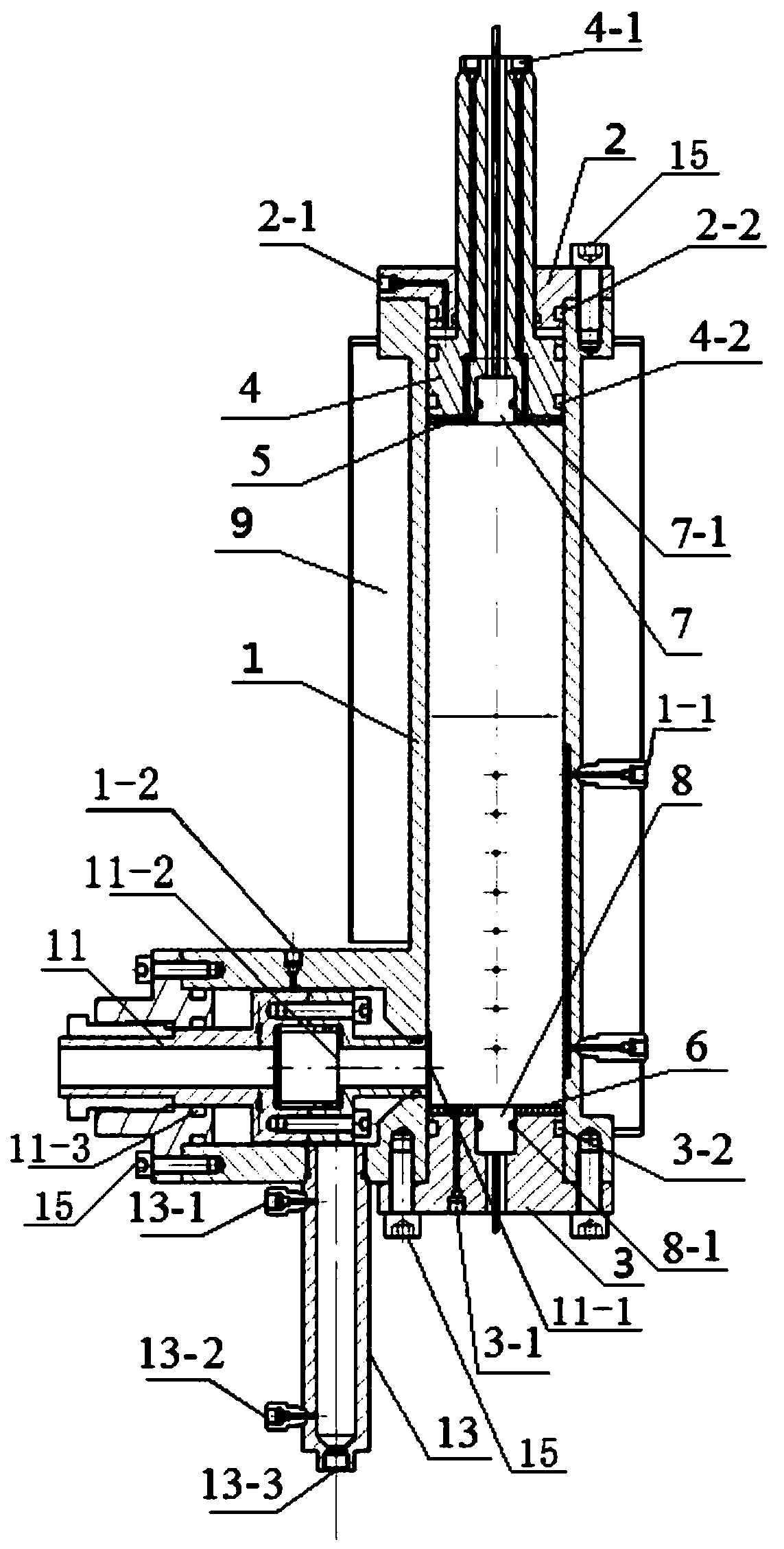

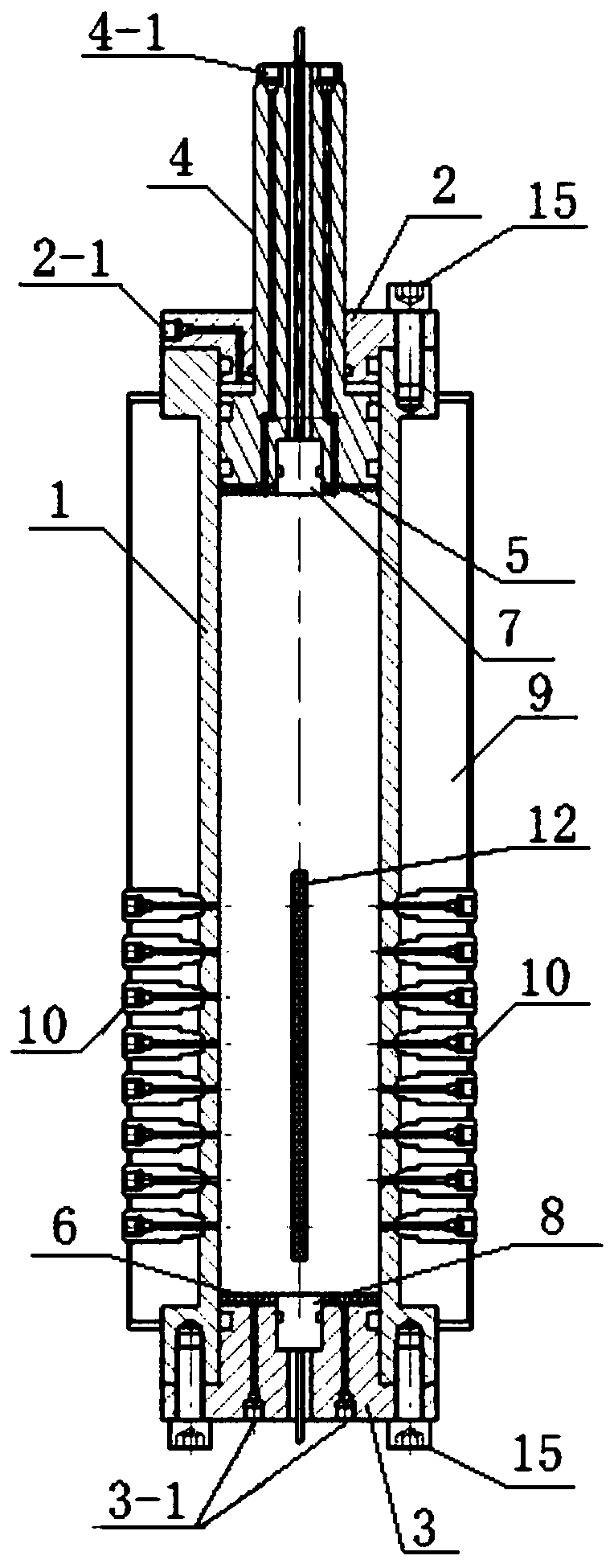

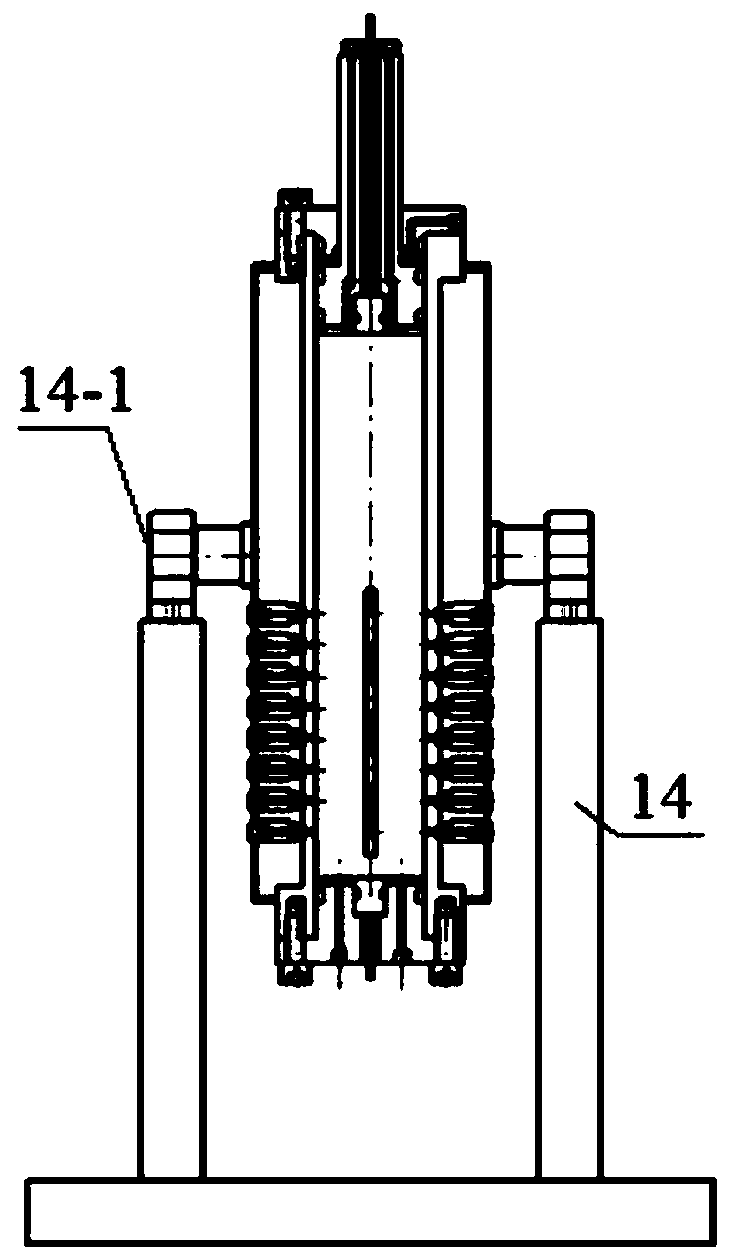

[0027] Such as Figure 1-2 As shown, the embodiment of the present invention provides a multifunctional reaction kettle for hydrate mining reservoir response and sand production simulation, including: a kettle body 1, an upper end cover 2 and a lower end cover respectively located at the top and bottom of the kettle body 1 3. The piston 4 passing through the upper end cover 3 , the plug 11 arranged on the side of the kettle body 1 , and the water-cooled jacket 9 arranged on the periphery of the kettle body 1 . The upper end cover 2, the lower end cover 3, and the plug 11 can all be connected to the kettle body 1 through a fixing device 15. Preferably, the fixing device 15 can be a combination of nuts and bolts. The reaction kettle can be used for consol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com