Deep oil reservoir high-temperature and high-pressure gas-displacing oil microcosmic visualization experiment method

A high-temperature, high-pressure, experimental method technology, applied in the direction of TV, color TV, electrical components, etc., can solve the problems that rocks are not easy to wash, it is difficult to reproduce the high temperature and high pressure conditions of real reservoirs, and the repeatability is low, so as to reduce the temperature and achieve flooding. Replacement pressure gradient control to ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

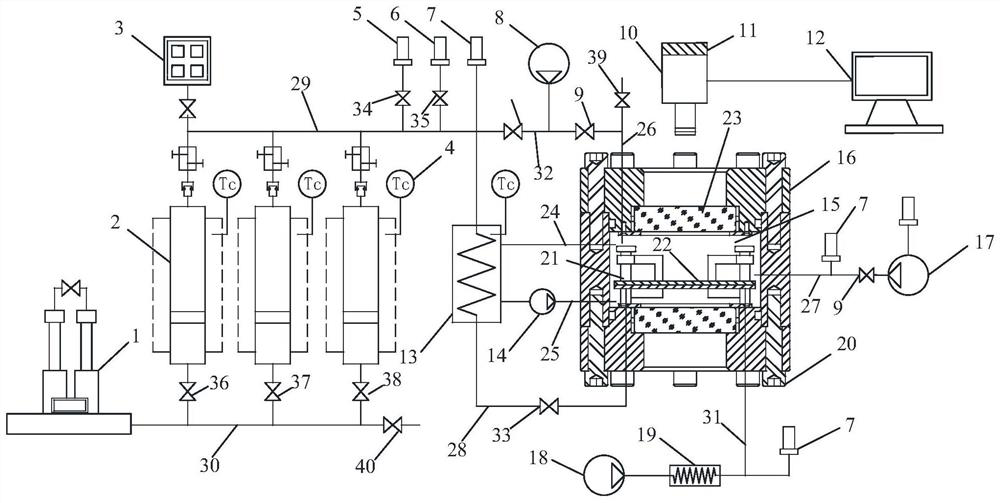

[0044] A microscopic visualization experimental method for high temperature and high pressure gas flooding in deep reservoirs, using a microscopic visualization experimental device, such as figure 1 As shown, it includes reservoir temperature and pressure coordinated control system, displacement response system, data acquisition and video recording system and auxiliary system. The main function of the reservoir temperature-pressure coordinated control system is to simulate the formation pressure and temperature of the rock formation in the real reservoir environment. The reservoir temperature and pressure coordinated control system includes a high-pressure sealing holder 16, on which a sapphire window 23 for easy observation is set, and a reservoir confining pressure ring cavity 15 is formed inside the high-pressure sealing holder 16 . The reservoir confining pressure ring cavity 15 is connected to the shell inlet of the high temperature heating vessel 13 through the fluid he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com