Fluid migration shut-off

a technology of fluid migration and shut-off, which is applied in the direction of fluid removal, earthwork drilling and mining, and wellbore/well accessories, etc., can solve the problems of debris caught in the valve, wear or degradation of the valve, and the performance of the check valve is not always adequate to prevent all fluid migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]A detailed description of one or more embodiments of the disclosed apparatus and method are presented herein by way of exemplification and not limitation with reference to the Figures.

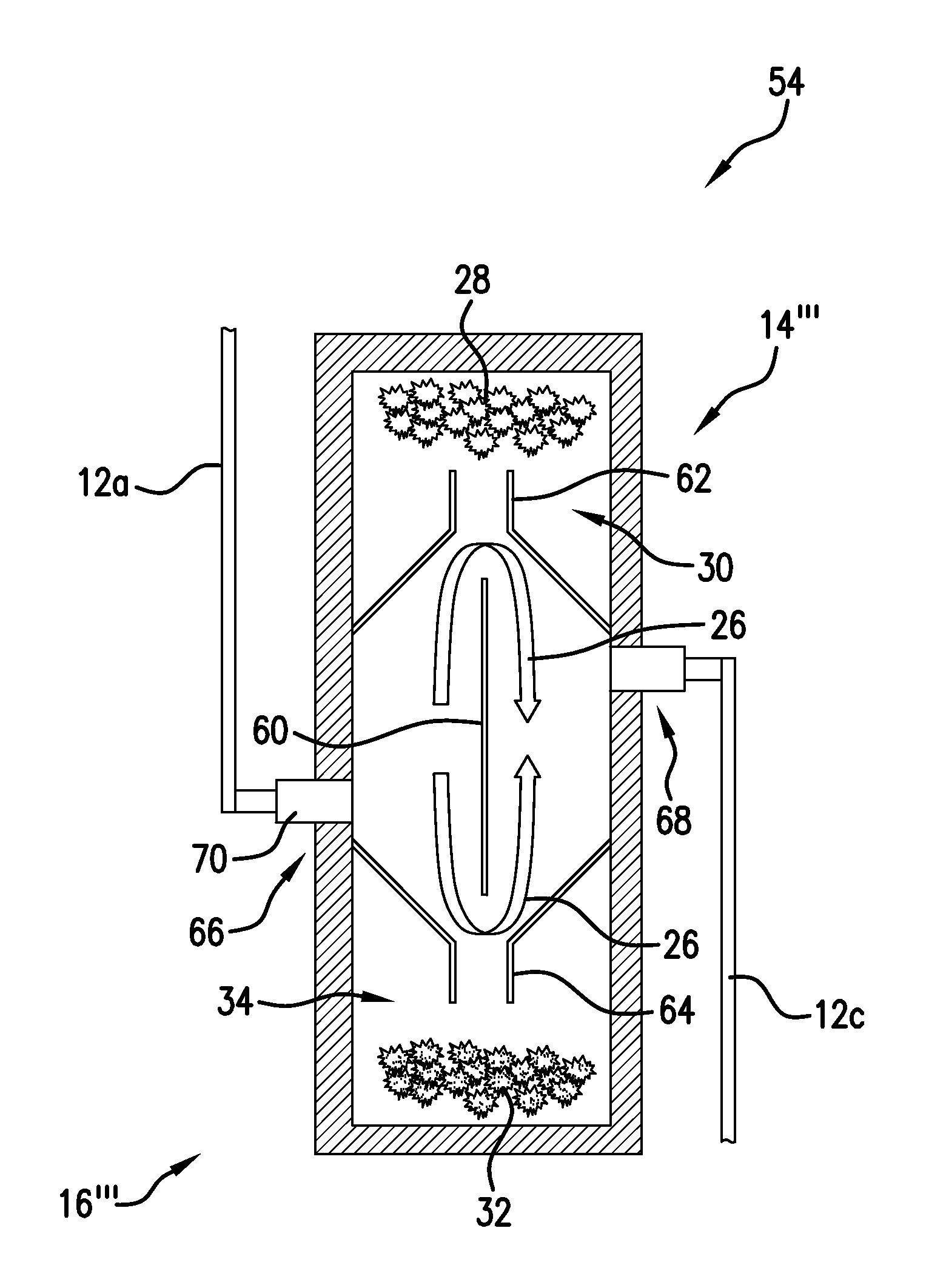

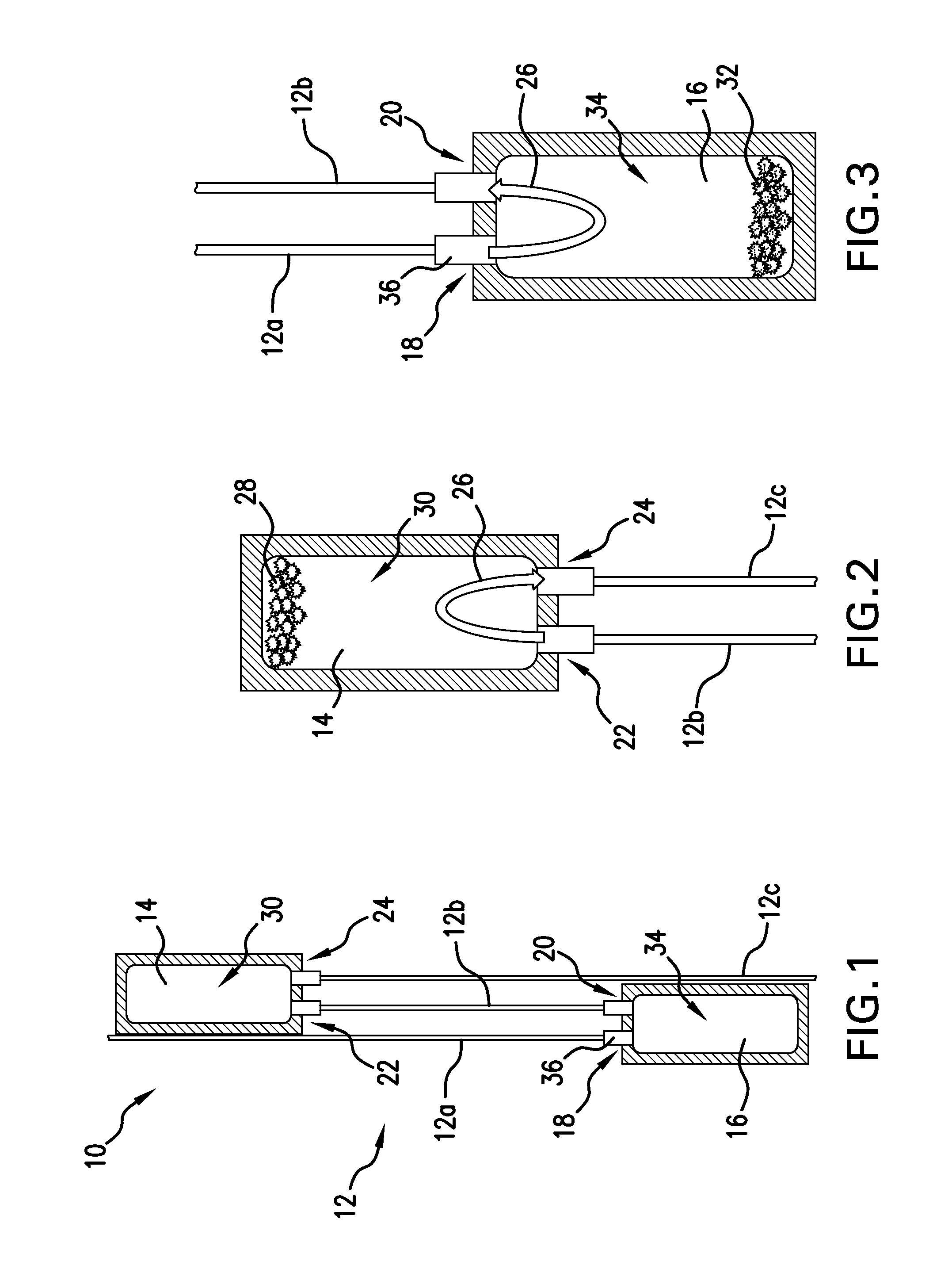

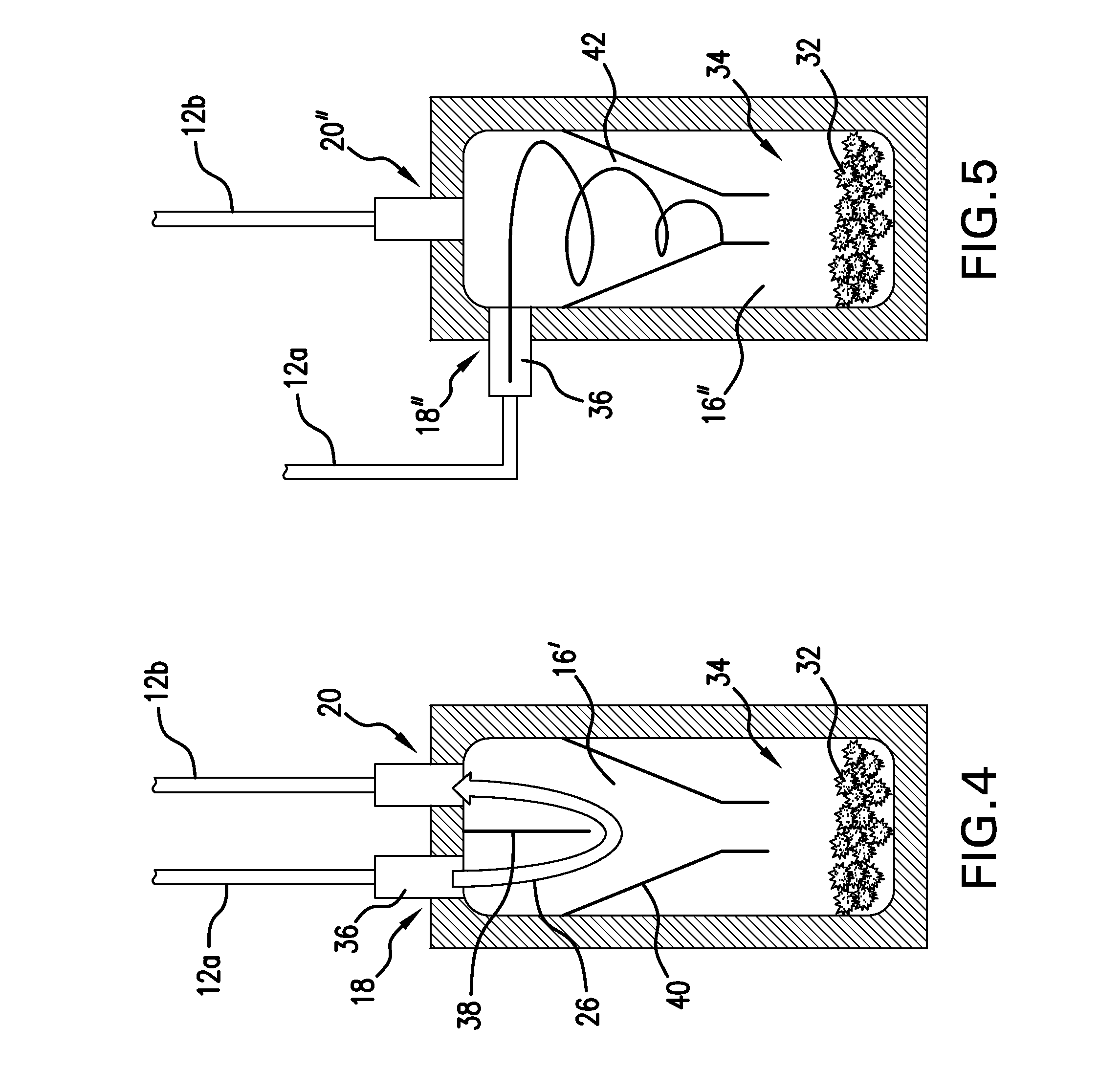

[0015]Referring now to FIG. 1, an assembly 10 is shown. The assembly 10 is included along a chemical injection line 12. The chemical injection line 12 is arranged in a borehole spanning between a surface in which the borehole is made (e.g., a surface of the Earth) and production tubing in the borehole for enabling operators at the surface to inject chemicals or the like downhole, such as demulsifiers, clarifiers, corrosion inhibitors, scale inhibitors, dewaxers, surfactants, etc., for aiding in production. The assembly 10 is arranged to prevent the migration of natural gas or other fluids, up the injection line 12 to the surface.

[0016]The assembly 10 includes a trap 14 and a debris catch 16. The chemical injection line 12 comprises several sections, namely, lines 12a, 12b, and 12c. The line 12a i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com