Flexible pressurizing and damping device for drill bit

A shock-absorbing device and a flexible technology, applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of low drilling pressure, difficult to control the drilling rate, and low ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

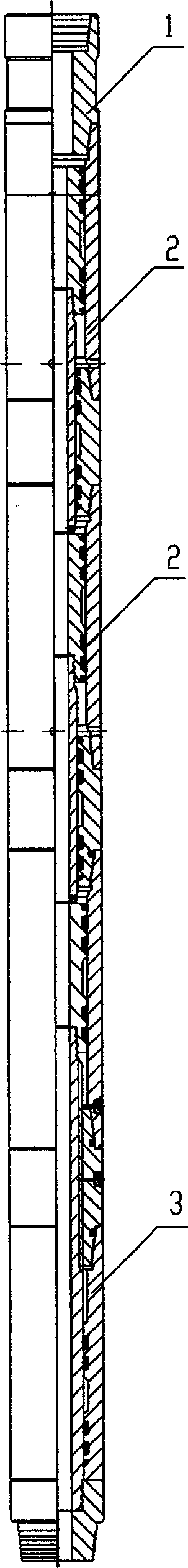

[0025] Such as figure 1 As shown, this example consists of an upper joint 1 that can be connected with the drill string, two sets of hydraulic boosters 2, a power flexible converter 3 and a lower joint 4 that can be connected with the drill bit. The pressure booster 2 is connected to the upper joint 1, two groups of hydraulic boosters 2 are connected in series, and the hydraulic booster 2 at the bottom is connected to the power flexible converter 3.

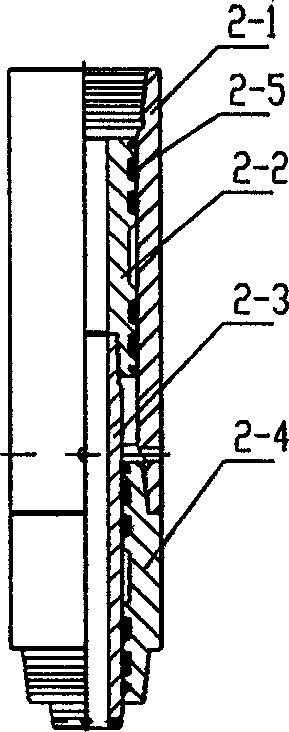

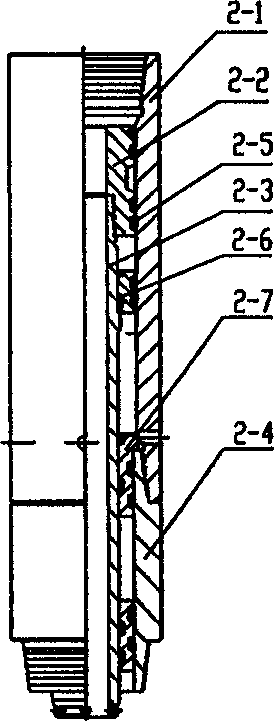

[0026] Such as figure 2 , the hydraulic booster 2 is mainly composed of a hydraulic cylinder A 2-1, a hollow piston A 2-2, a hollow central shaft 2-3, and a shaft sleeve A 2-4. The upper end of the hydraulic cylinder A 2-1 Set the internal thread threadedly connected with the upper joint or with the lower end of the shaft sleeve A 2-4 of the previous group of hydraulic booster 2, the shaft sleeve A 2-4 is threaded at the lower end of the hydraulic cylinder barrel A 2-1, and the piston A 2 -2 is threadedly connected with the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com