Continuous circulation drilling well system

A drilling and drill pipe technology, applied in the field of continuous circulation drilling system, can solve the problems of interruption of drilling fluid circulation, etc., to ensure continuous circulation, reduce downhole complex situations and downhole accidents, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

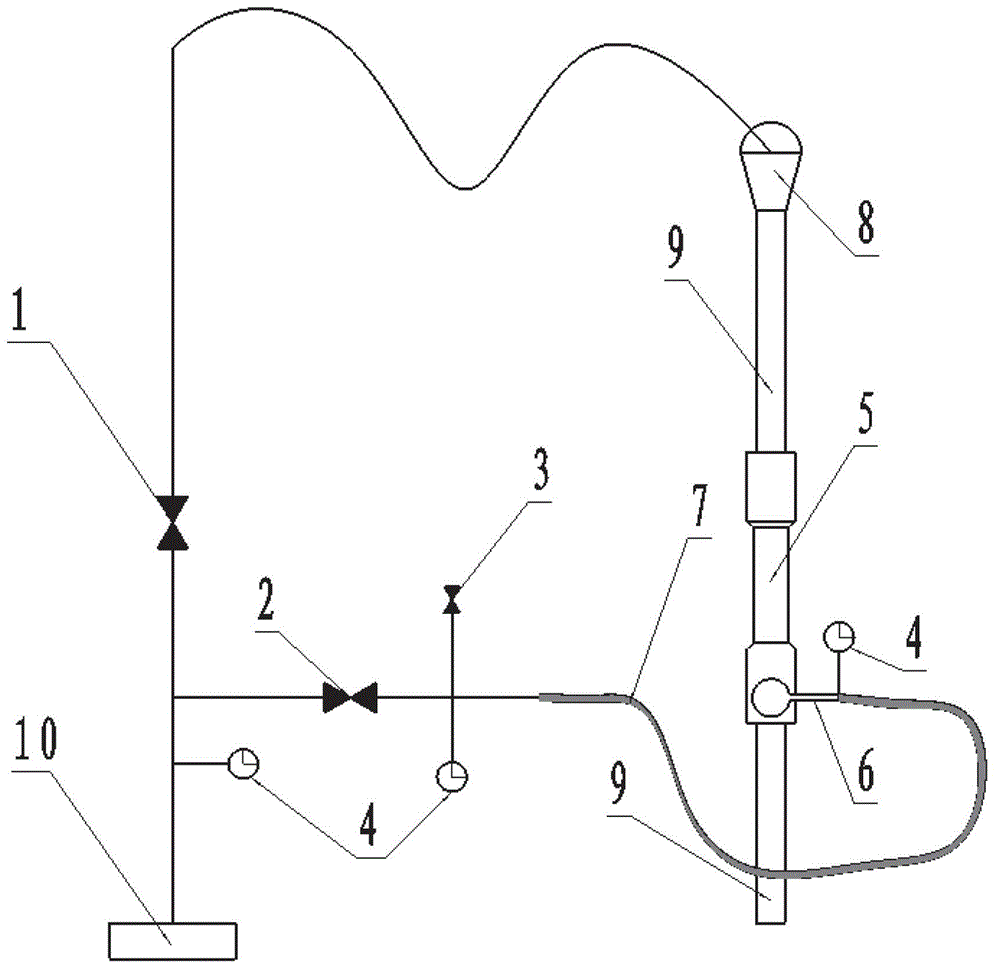

[0008] As shown in the accompanying drawings, a continuous circulation drilling system includes a faucet 8, a drill pipe 9 and a mud pump 10; a pressure gauge 4 is arranged on the pipeline at the upper end of the mud pump 10, and the mud pump 10 is connected to the standpipe valve 1 through the pipeline, and the standpipe The valve 1 is connected to the faucet 8 through the pipeline, and the faucet 8, the drill pipe 9, the continuous circulation nipple 5, and the drill pipe 9 are connected in sequence. The joint 6 is connected to the hose 7, and the hose 7 is connected to the branch valve 2 through the pipeline. The pipeline between the hose 7 and the branch valve 2 is provided with a pressure relief valve 3 and a pressure gauge 4, and the branch valve 2 is connected to the mud through the pipeline. pump 10.

[0009] During normal drilling, the standpipe valve 1 is opened, the branch valve 2 is closed, the continuous circulation nipple 5 is in the straight-through state, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com