Electronic-grade sulfuric acid production system and production process

A sulfuric acid production, electronic-grade technology, applied in the direction of sulfur trioxide/sulfuric acid, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of easy clogging system, low production efficiency, inconvenient disassembly and cleaning, etc., to ensure continuous circulation , reliable impurity removal, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

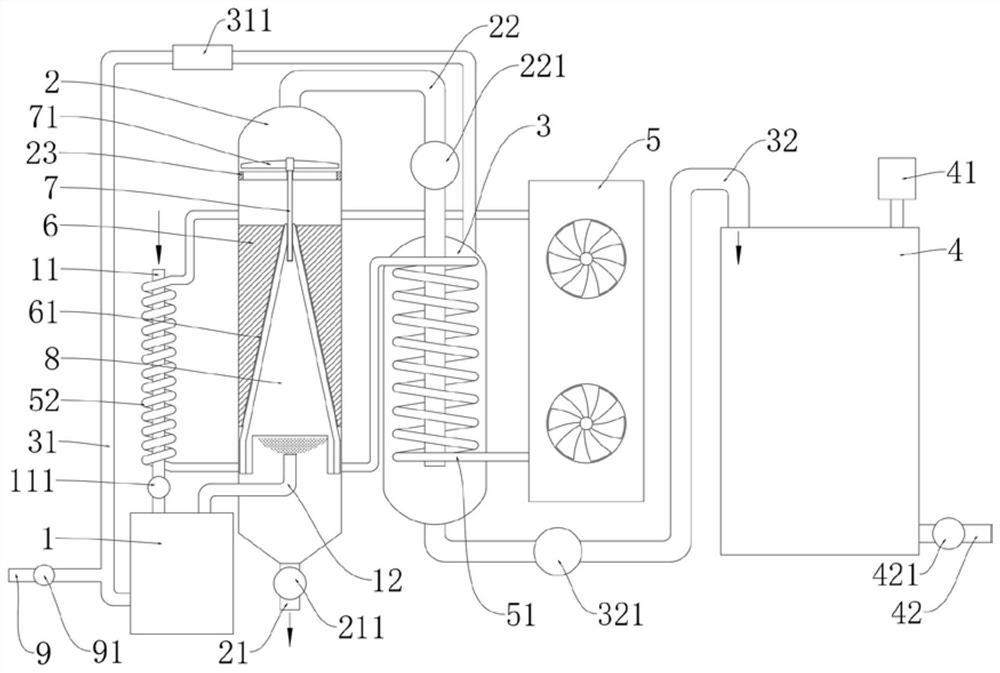

[0037] refer to Figure 1-2 , an electronic grade sulfuric acid production system comprising:

[0038] Ultrasonic atomizer 1, used to atomize standard industrial-grade concentrated sulfuric acid into fine particles through ultrasonic vibration;

[0039] Evaporation tank 2 is used to heat and evaporate the concentrated sulfuric acid atomized into fine particles to form sulfuric acid vapor;

[0040] Condensation tank 3 is used to condense sulfuric acid vapor into sulfuric acid liquid;

[0041] The liquid storage tank 4 is used to store the condensed sulfuric acid liquid;

[0042] The radiator 5 is used to reduce the heat of the steam sulfuric acid in the condensation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com