Biological waste treatment plant

A technology of biological treatment and treatment tank, applied in the direction of bio-organic part treatment, chemical/physical process, educts, etc., can solve the problems of screw propeller elevation, correction, difficult temperature control, etc., and achieve the effect of reducing air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

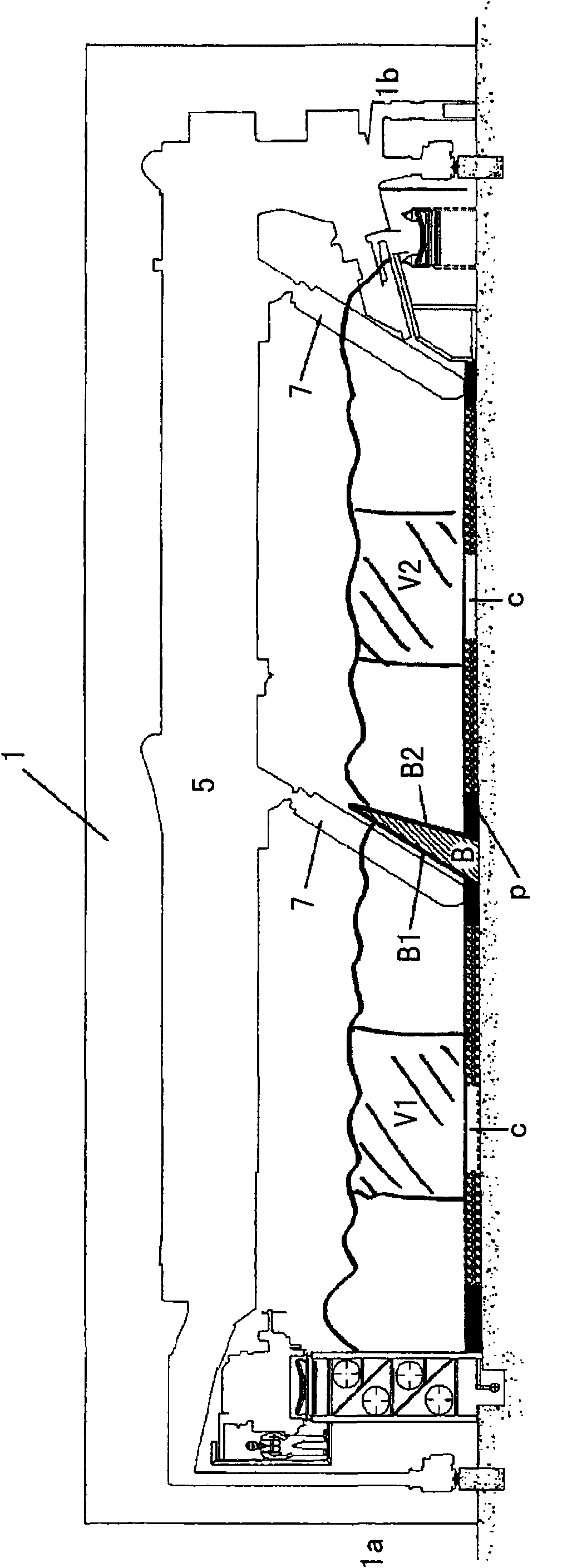

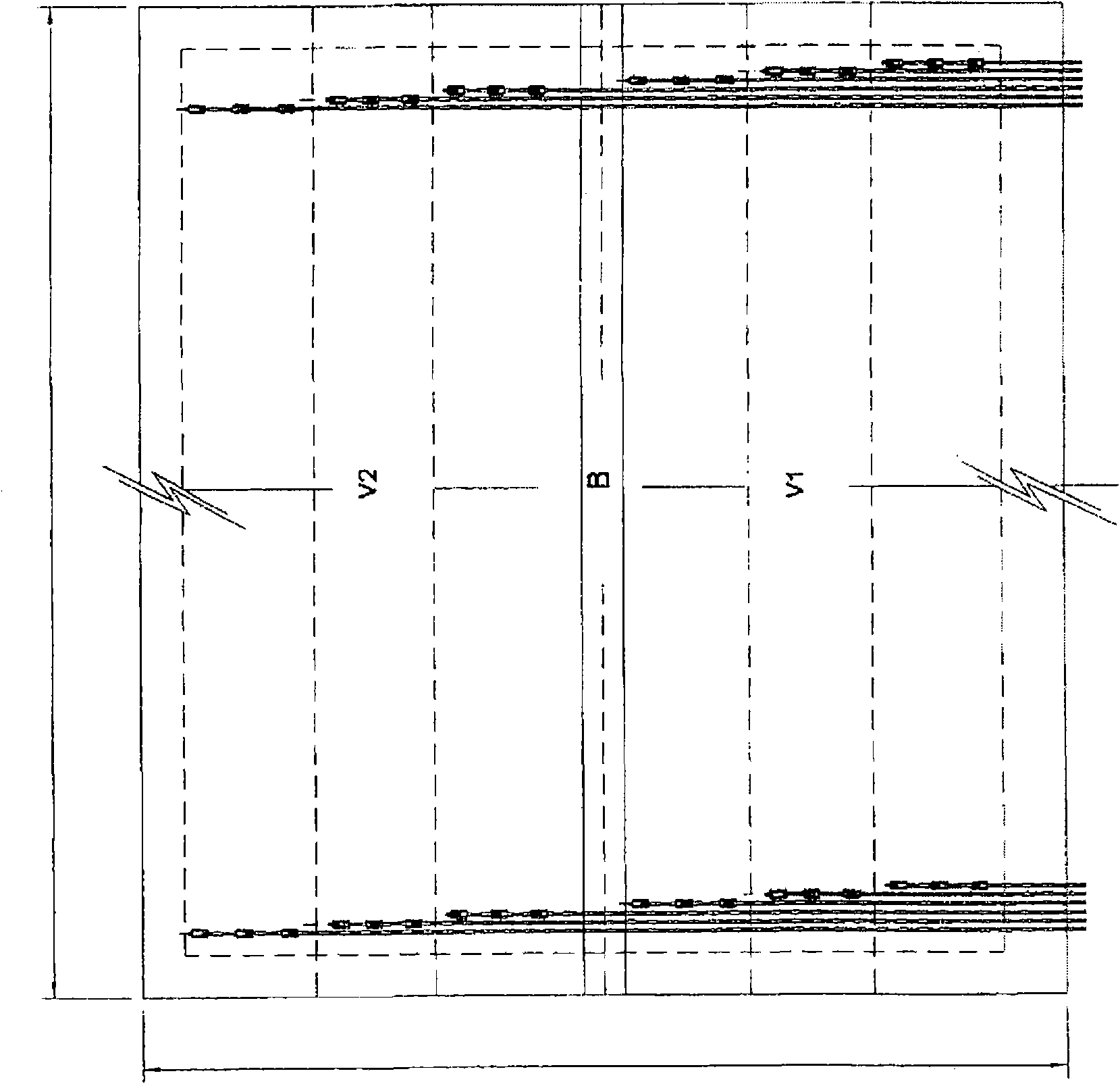

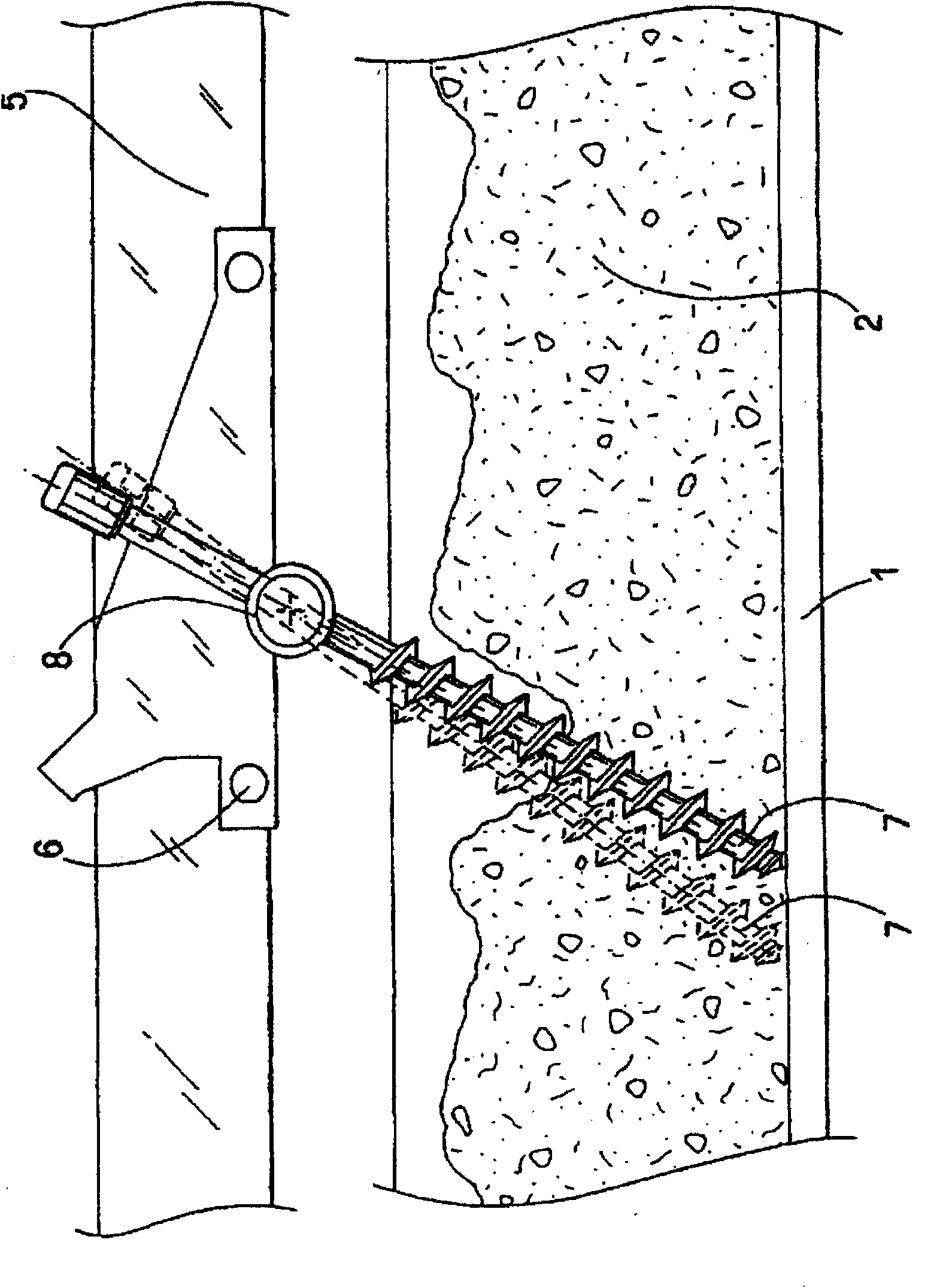

[0038] Reference is now made to the accompanying drawings and in particular to the figure 1 , organic matter 2( figure 1 (not shown in ) is fed into the treatment tank 1 by means of a conveyor belt or the like, preferably in a continuous manner. Above the treatment tank 1 is a bridge 5 along which two or more trolley wheels run, on which a set of one or more screw pushers 7 are mounted, characterized in that: (i) they wind around themselves axis of rotation, and are carried by the bridge 5 to move from the end of the treatment tank 1 to the opposite end; (ii) they move along the bridge 5 across the treatment tank 1 from one end to the opposite end; (iii) they can pass around their Axis of rotation 8 ( figure 1 (not shown in ) are turned over so that they can be drawn out of the organic matter when required.

[0039] image 3 A preferred embodiment of the working position of the screw propellers 7 is shown, which, although they all sweep the bottom of the treatment tank, ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com