Crankshaft for Equal Distribution Angle Hydraulic Cylinder Motor

A hydraulic cylinder, equal distribution technology, applied in the crankshaft and other directions, can solve the problems of large diesel consumption, potential safety hazards, and potential safety hazards of high temperature hot gas, so as to achieve stable output speed and torque, reduce accident rates, and reduce beating amplitude. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

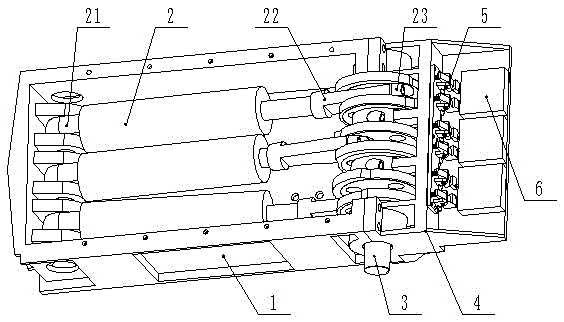

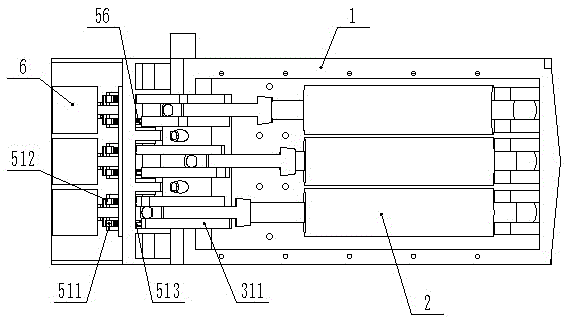

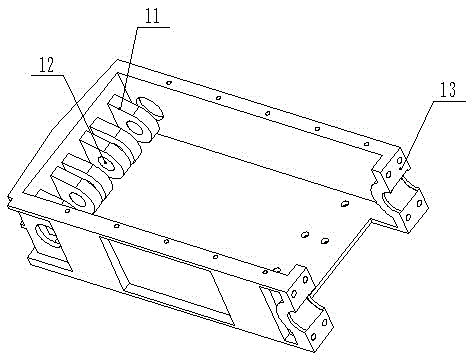

[0031] Such as figure 1 — image 3 As shown, the equal distribution angle hydraulic cylinder motor includes a box body 1, three hydraulic cylinders 2, a crankshaft 3, a front end assembly of the box body 4, and a control system 5. The box body 1 is a shell structure as a whole, and the inside of the box body 1 Three earrings 11 for installing the hydraulic cylinder 2 are arranged side by side at the rear end of the box. The earrings 11 are provided with a hydraulic cylinder installation hole 12. The front end of the box body 1 is provided with a box semicircular seat 13 for installing the crankshaft 3. The box The body semicircular seat 13 is provided with a threaded hole connected with the box front end assembly 4; The internal hydraulic cylinder installation hole 12 is fixedly connected, and the hydraulic cylinder piston end 22 is connected to the crankshaft 3 through the piston end cover 23. The reciprocating motion of the hydraulic cylinder 2 drives the crankshaft 3 to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com