A robot-based deicing method for overhead transmission lines

A technology for overhead transmission lines and robots, which is applied to overhead lines/cable equipment, overhead installation, electrical components, etc., can solve problems such as low efficiency, hidden safety hazards, construction difficulties, and threats to the life safety of electric workers, so as to prevent safety accidents and ensure De-icing efficiency, the effect of reducing the runout amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

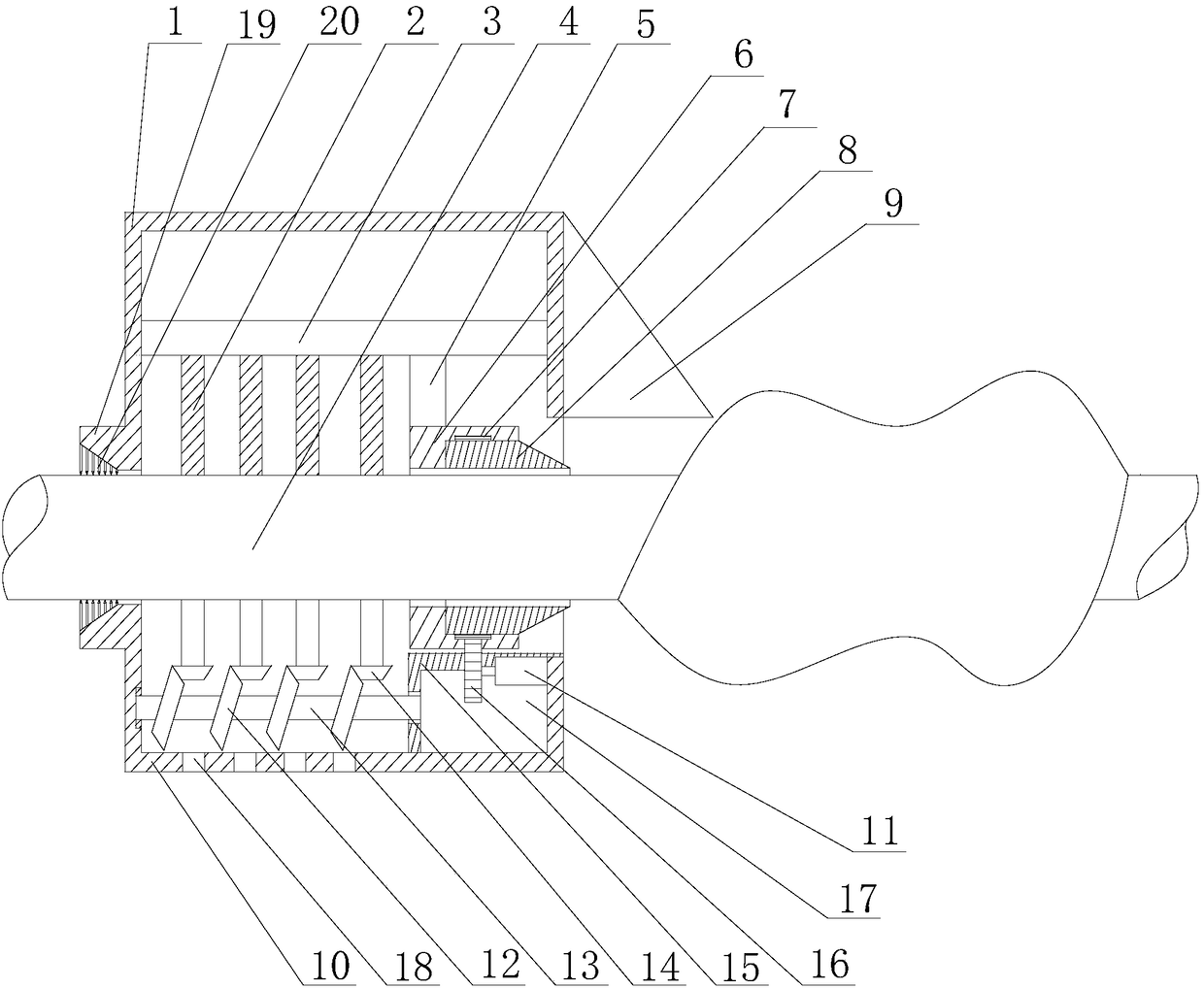

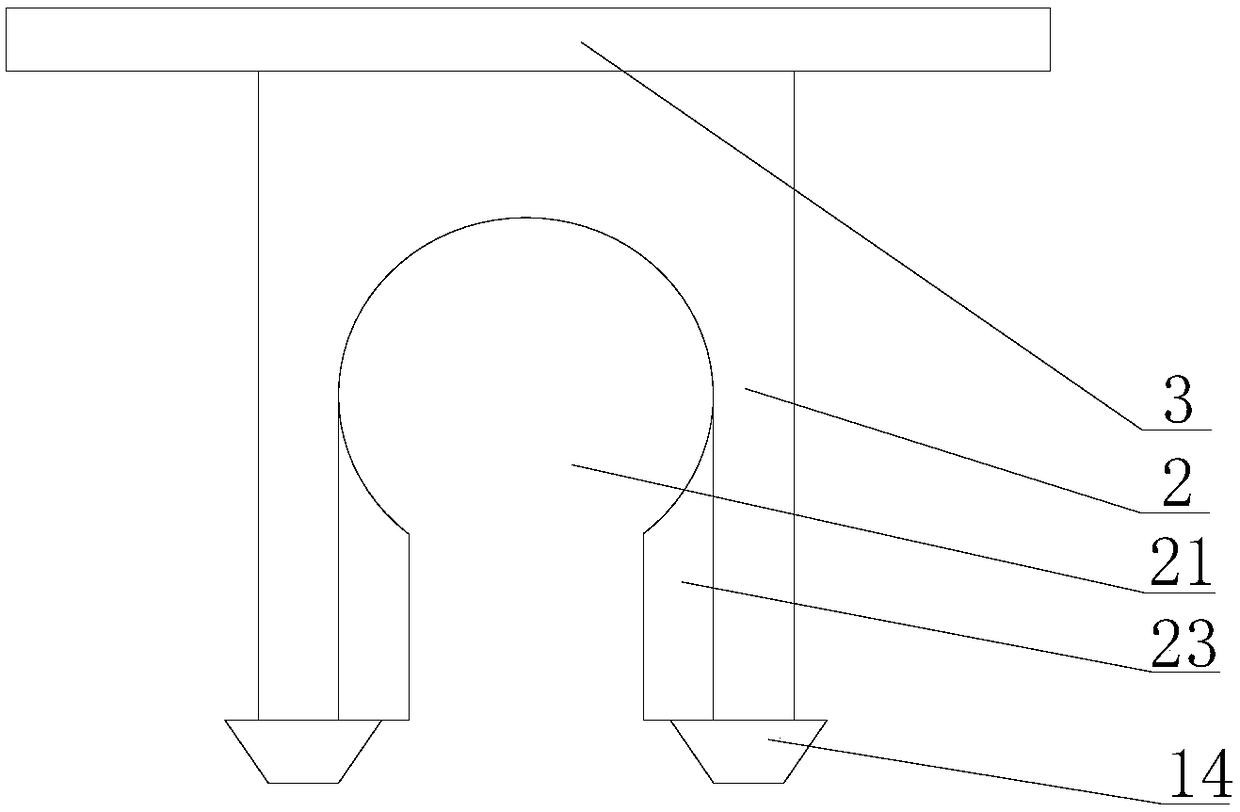

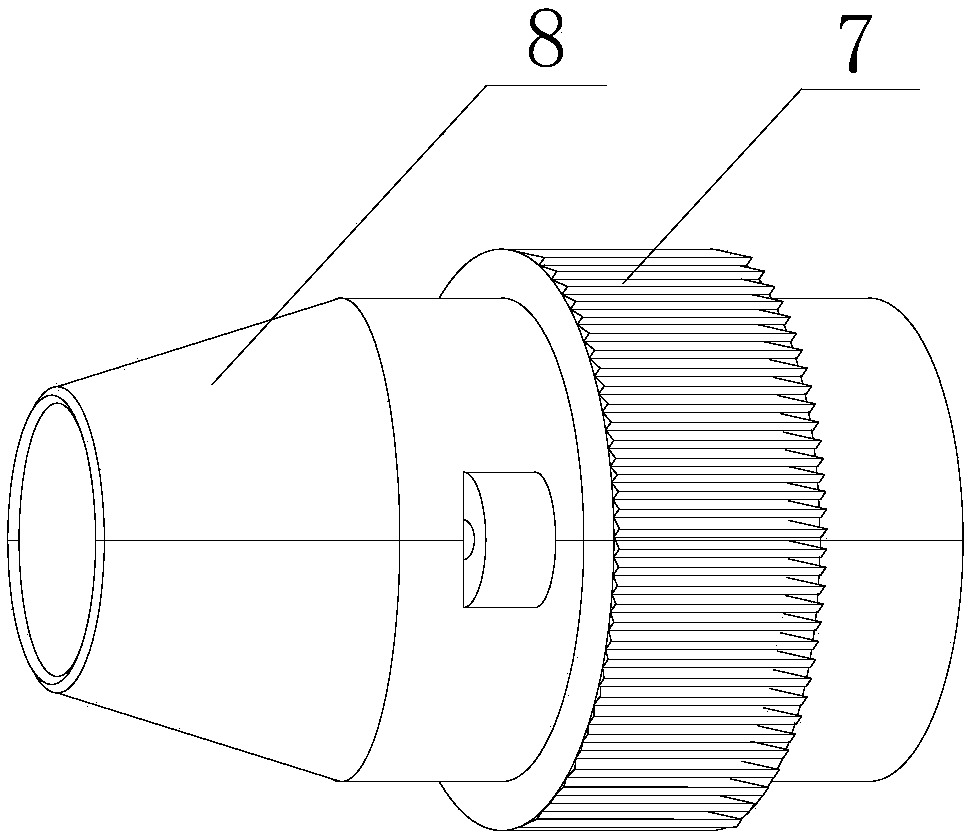

[0031] Such as Figure 1~5 As shown, this embodiment includes the following steps: firstly, two semi-circular de-icing plates are sleeved on the outer wall of the cable, and then the non-hinging ends of the two de-icing plates are connected by a snap connection to form a ring De-icing head, then snap the upper shell onto the cable so that the U-shaped openings on the multiple clamping plates directly contact the cable, then close the lower shell and the upper shell, and use bolts to The upper shell and the ear plate on the side wall of the lower shell are connected and fixed, the upper ring and the lower ring are aligned and form a closed columnar area. At the same time, the stepper motor and the drive motor are started to drive the gear at the output end of the motor After passing through the connecting hole, it is matched with the toothed belt to drive the de-icing head to make a circular motion. The de-icing head starts to rotate rapidly in the columnar area. At the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com