Winding machine

A technology of winding machine and unwinding mechanism, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc. It can solve the problems of small number of transport wheels, tight or too loose mica tape, and exceeding the winding range, etc. Achieve the effects of reducing the jumping range, improving the stress condition, the fit condition and the flatness of the end surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

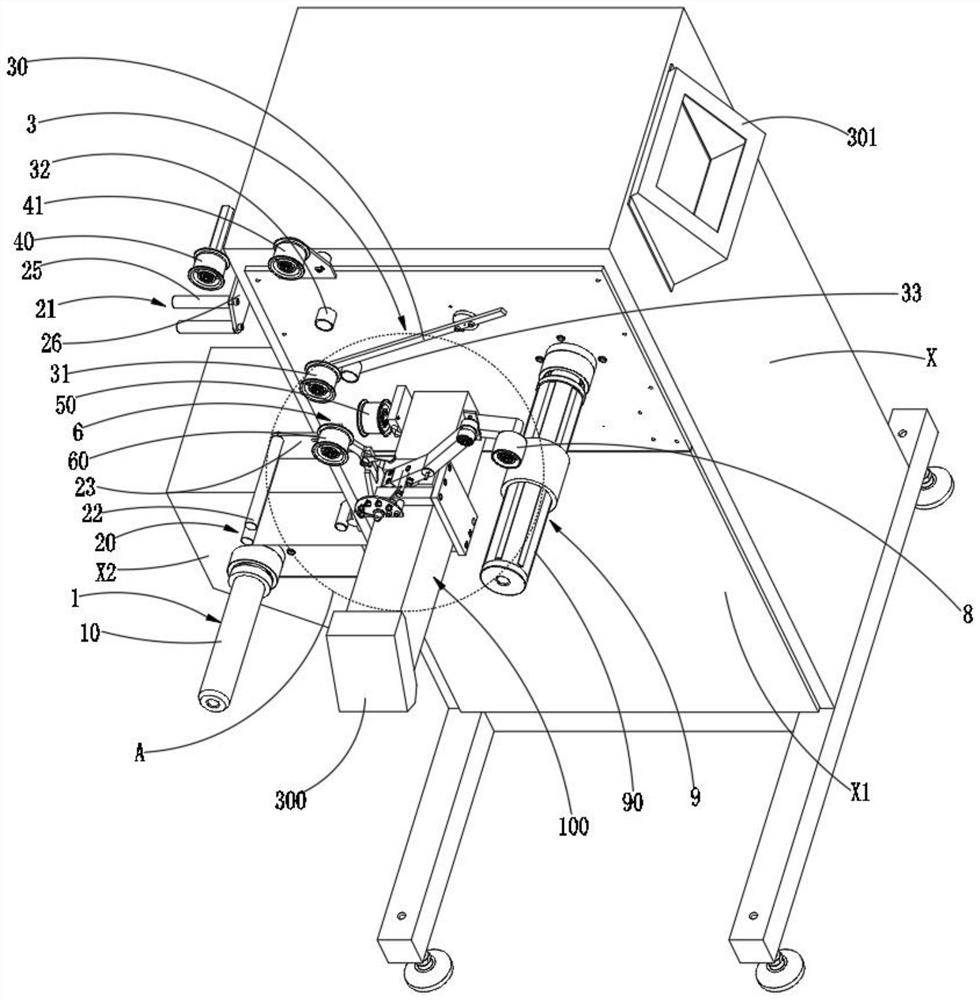

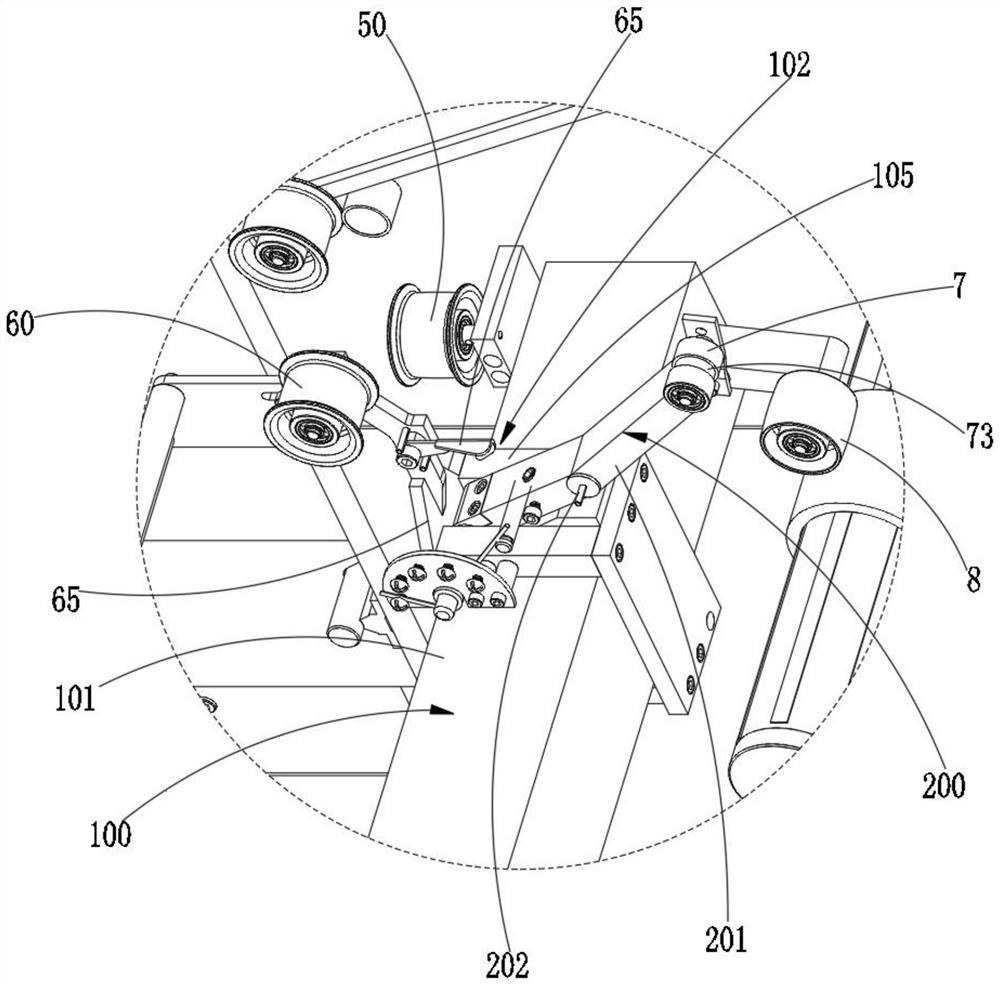

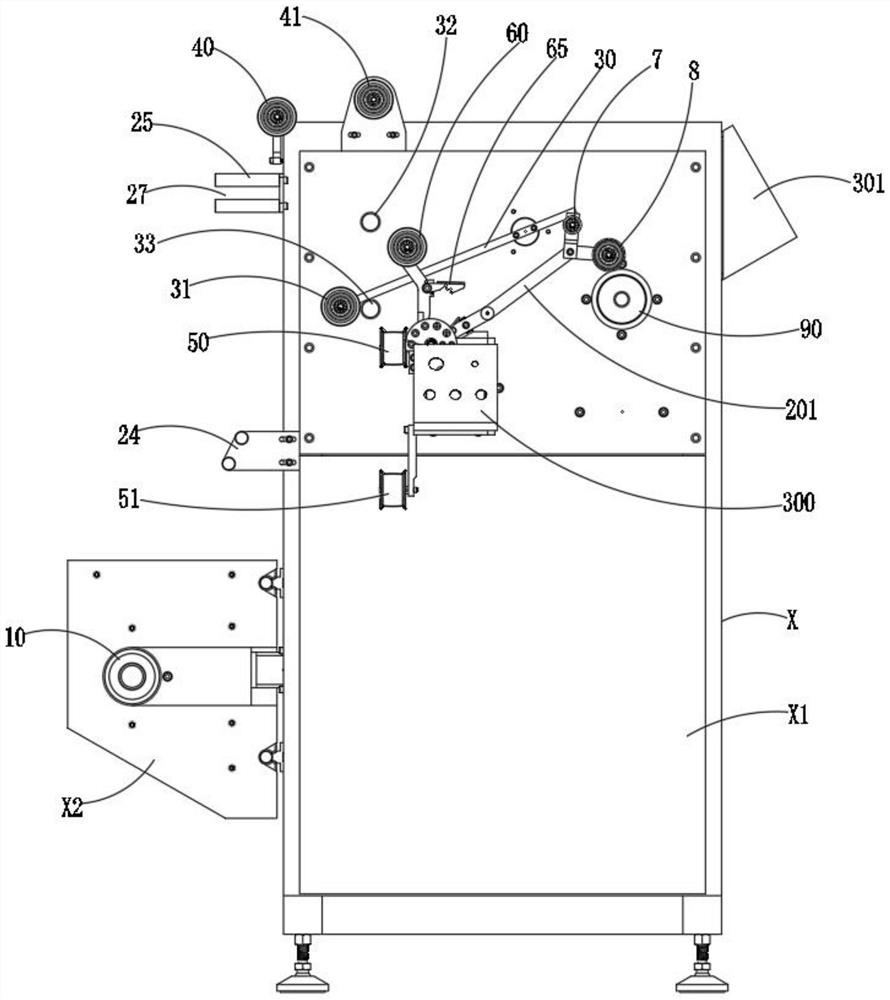

[0041] As an optimization scheme of the embodiment of the present invention, please refer tofigure 1 , figure 2 and image 3 , the unwinding mechanism 1 includes a placement shaft 10 for placing raw materials and a locking member 11 for locking raw materials on the placement shaft 10, and the placement shaft 10 is installed on the vertical installation surface of the machine body X On X1, the locking member 11 is installed on the installation shaft 10 . In this embodiment, the locking of the raw material can be ensured by arranging the shaft 10 and the locking member 11, so as to avoid the problem that the raw material is detached during the working process, which will affect the feeding.

[0042] To further optimize the above scheme, please refer to figure 1 , figure 2 , image 3 and Figure 4 , the placement shaft 10 includes a shaft body for the raw material sleeve, the shaft body is installed on the body X, and the end of the shaft body far away from the body X is p...

Embodiment 2

[0047] As an optimization scheme of the embodiment of the present invention, please refer to figure 1 and image 3 , the clipping mechanism includes a first clipping assembly 20 for the first clipping, the first clipping assembly 20 includes two parallel first optical axes 22 and two first optical axes 22, the first mounting plate 23 is installed, and the first mounting plate 23 is fixed on the body X. The interval between the two first optical axes 22 is the first limit for the mica tape to pass through. Range 24. In this embodiment, the limiting method is limited by the distance between the two first optical axes 22, so as to limit the swing amplitude of the mica tape within this range. Preferably, the two first optical axes 22 are parallel to the shaft body of the installation shaft 10 .

[0048] As an optimization scheme of the embodiment of the present invention, please refer to figure 1 and image 3 , the limiting mechanism also includes a second limiting component ...

Embodiment 3

[0053] As an optimization scheme of the embodiment of the present invention, please refer to figure 1 and image 3 , the buffer device 3 includes a movable rod 30 that can swing back and forth and a buffer roller 31 that is partially wrapped by the mica tape, and the position that the mica tape is wrapped on the buffer roller 31 is located Below, and the buffer roller 31 is installed on one end of the movable rod 30, the other end of the movable rod 30 is hinged on the body X, and the movable rod 30 is installed on the buffer roller 31 The swing track at one end is consistent with the direction in which the mica tape is transported. In this embodiment, the mica tape will lift the buffer roller 31 upwards, and it will sink due to gravity, so it can play a buffering effect and play the function of real-time tensioning of the mica tape. Preferably, the buffer device 3 further includes a driving member for driving the movable rod 30 to move. The driving method can be gravity si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com