A water-retaining method for a core drilling machine

A core drilling machine and core drilling technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of large beating, the cooling water is easy to get wet and dirty the operator's work clothes, and it is difficult to drill, so as to reduce the beating amplitude. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

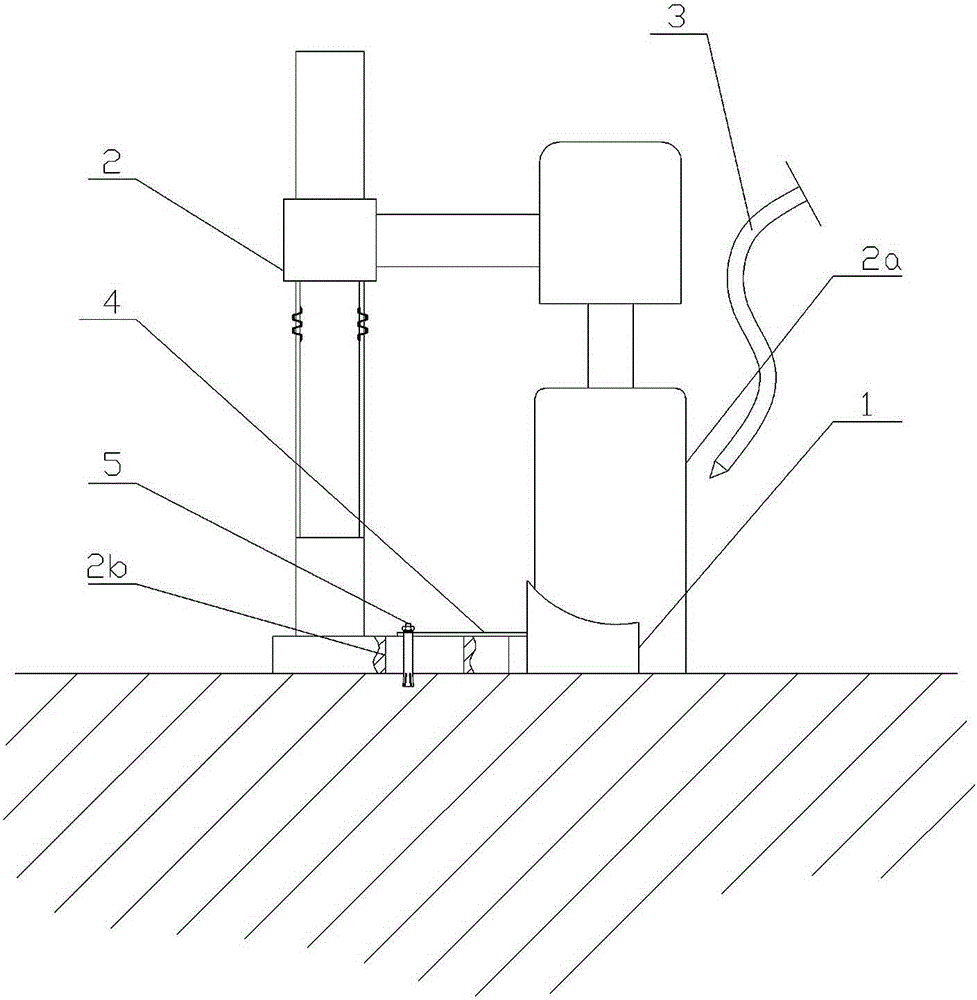

[0012] like figure 1 As shown, a water retaining method for a core drilling machine provided by the present invention includes that the base of the core drilling machine is provided with a chute 2b, and an expansion bolt 5 is arranged in the chute, and the expansion bolt 5 is in clearance fit with the chute 2b. There is a connecting rod 4, and the other end of the connecting rod is connected with a semicircular sleeve 1, and the inner wall of the semicircular sleeve 1 is in clearance fit with the thin-walled drill bit 2a.

[0013] work process

[0014] During on-site inspection, the core drilling machine 2 is first installed and adjusted to the core-taking position, and then the thin-walled drill bit 2a is installed, the gap between the thin-walled drill bit 2a and the inner wall of the semicircular sleeve 1 is adjusted, and the cooling water 3 is connected. Start the motor, and the thin-walled drill moves down along the inner wall of the semicircular sleeve. When it touches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com