Double-aggregate composite polymer, and pouring method and application thereof

A composite, high-polymer technology, used in earth-moving drilling, wellbore lining, tunnel lining, etc., to achieve the effect of enhancing antistatic and flame retardancy, low price and reducing use cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

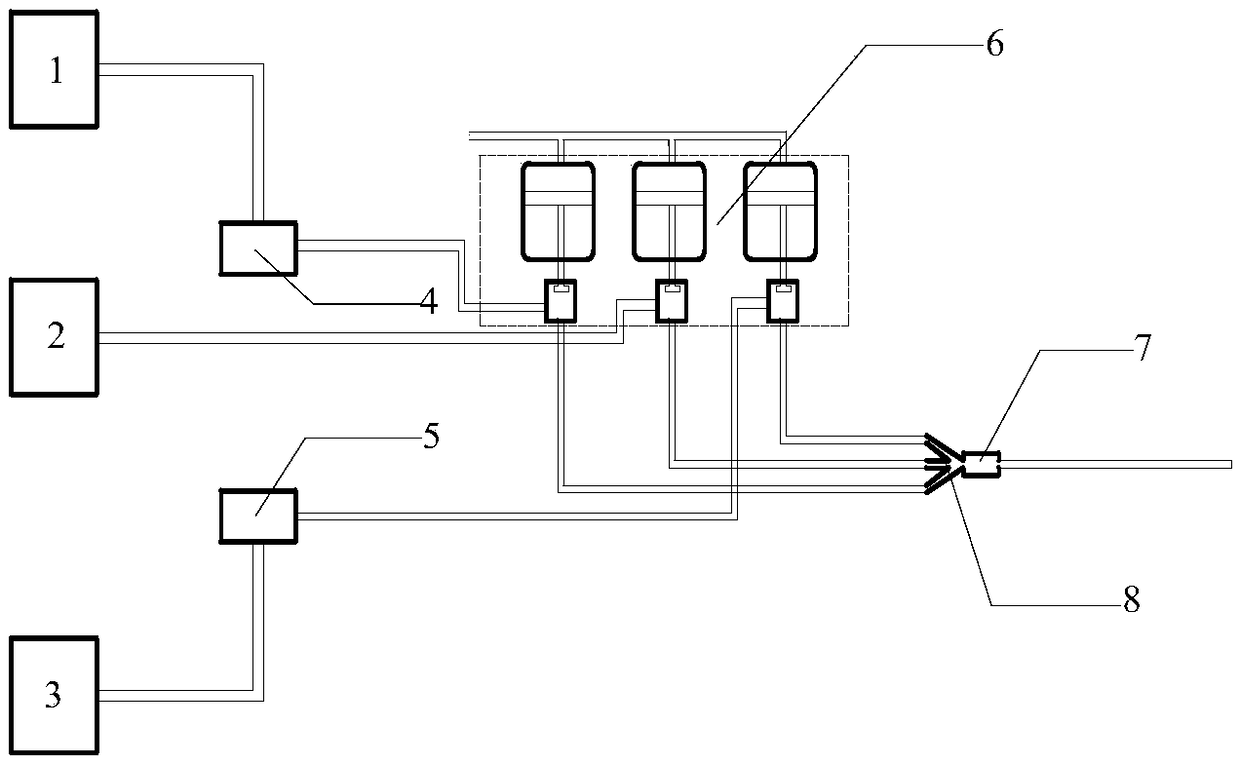

[0035] A kind of grouting method of double-aggregate composite high polymer for coal seam reinforcement, such as figure 1 As shown, the steps are as follows:

[0036] (1) Select 7 parts of pebbles with a particle size of 6 mm and 35 parts of stone powder with a particle size of 2 mm to measure the bulk density and apparent density of the pebbles and stone powder.

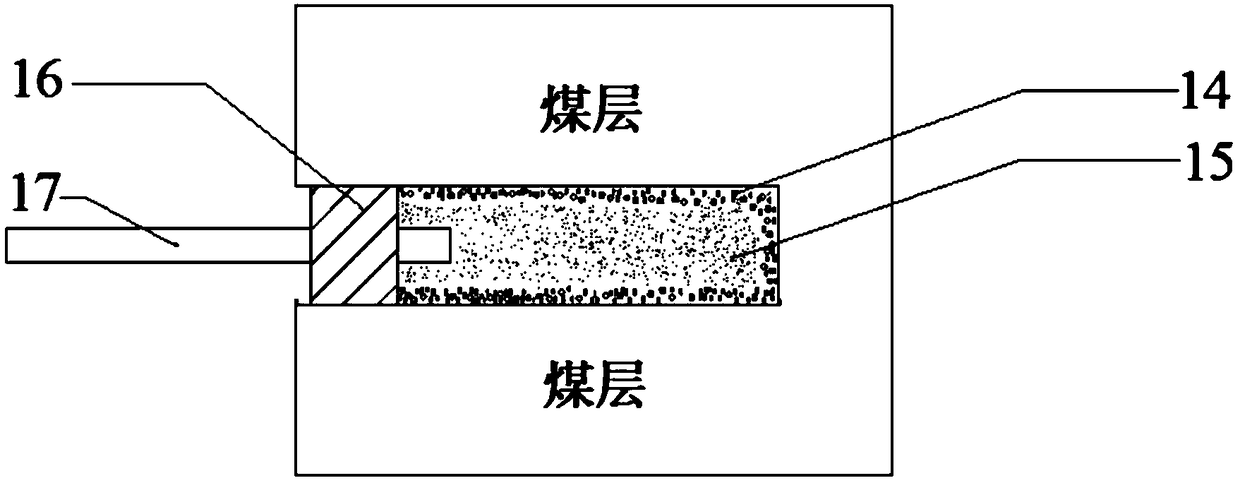

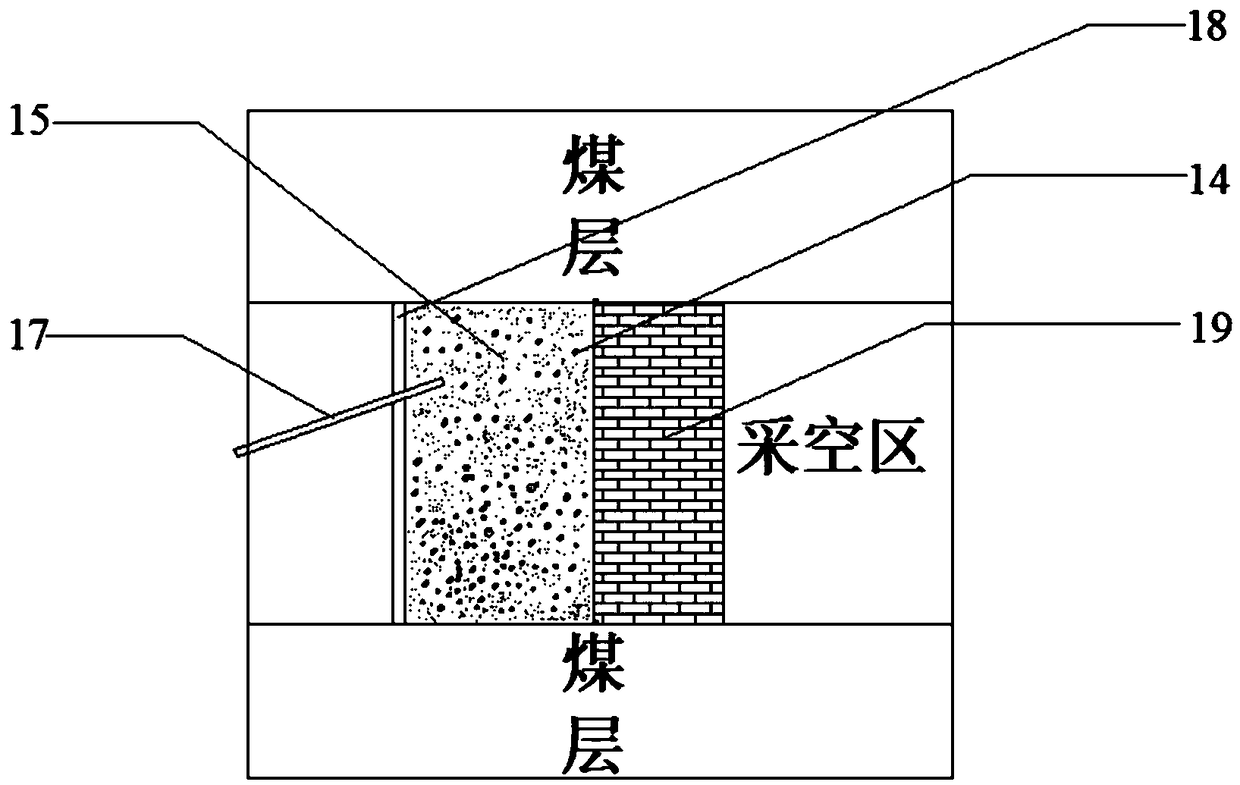

[0037] (2) Modify the screened coarse aggregate 14 and fine aggregate 15 with a modifier, treat with a modifier, and transport 30 parts of polyoxypropylene polyol in container I1 through a pneumatic lifting pump Go to the mixing chamber I4 and mix and stir 7 parts of modified pebbles for 3 minutes, add 5 parts of barium stearate for dispersion treatment until the outer layer is evenly distributed, then add 3 parts of dimethylthiotoluenediamine in sequence, 3 parts of triphenyl phosphate and 3 parts of stannous octoate were stirred in the mixing chamber I4 for 3 minutes and then sent to the grouting pump 6, and the ...

example 2

[0045] A kind of grouting method of double-aggregate composite high polymer for air plugging in coal seam, such as figure 1 As shown, the steps are as follows:

[0046] (1) Select 35 pieces of crushed stone with a particle size of 7mm and 7 pieces of silicon powder with a particle size of 3mm, and measure the bulk density and apparent density of the crushed stone and silicon powder.

[0047] (2) Modify the screened coarse aggregate 14 and fine aggregate 15 with a modifier respectively. After treating with the modifier, pass 18 parts of polyoxypropylene polyol in container I1 through a pneumatic lifting pump Transport to the mixing chamber I4 and mix with 35 parts of modified gravel for 3 minutes, add 5 parts of barium stearate for dispersion treatment until the outer layer is evenly distributed, then add 3 parts of dimethylthiotoluenediamine in turn , 3 parts of triphenyl phosphate and 3 parts of stannous octoate were stirred in the mixing chamber I4 for 3 minutes and then se...

Embodiment 3

[0055] A kind of grouting method of double-aggregate composite high polymer for coal mine roof filling, such as figure 1 As shown, the steps are as follows:

[0056] (1) Select 40 parts of coarse waste residue with a particle size of 8 mm and 8 parts of fly ash with a particle size of 4 mm to measure the bulk density and apparent density of the coarse waste residue and fly ash.

[0057] (2) The screened coarse aggregate 14 and fine aggregate 15 are respectively modified with a modifier. After the modifier is used, 45 parts of polyoxypropylene polyol in the container I1 are passed through a pneumatic lifting pump Transport to the mixing chamber I4 and mix and stir 40 parts of the modified coarse waste residue for 0.5min, add 5 parts of barium stearate for dispersion treatment until the outer layer is evenly distributed, then add 4 parts of dimethylthiotoluene in sequence Diamine, 4 parts of triphenyl phosphate and 4 parts of stannous octoate were stirred in the mixing chamber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com