Bypass valve while drilling

A bypass valve, while drilling technology, applied in the field of drilling, can solve the problems of troublesome operation, short service life, many wearing parts, etc., and achieve the effects of easy operation, reducing the number of trips and downhole accidents, and reducing downhole accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

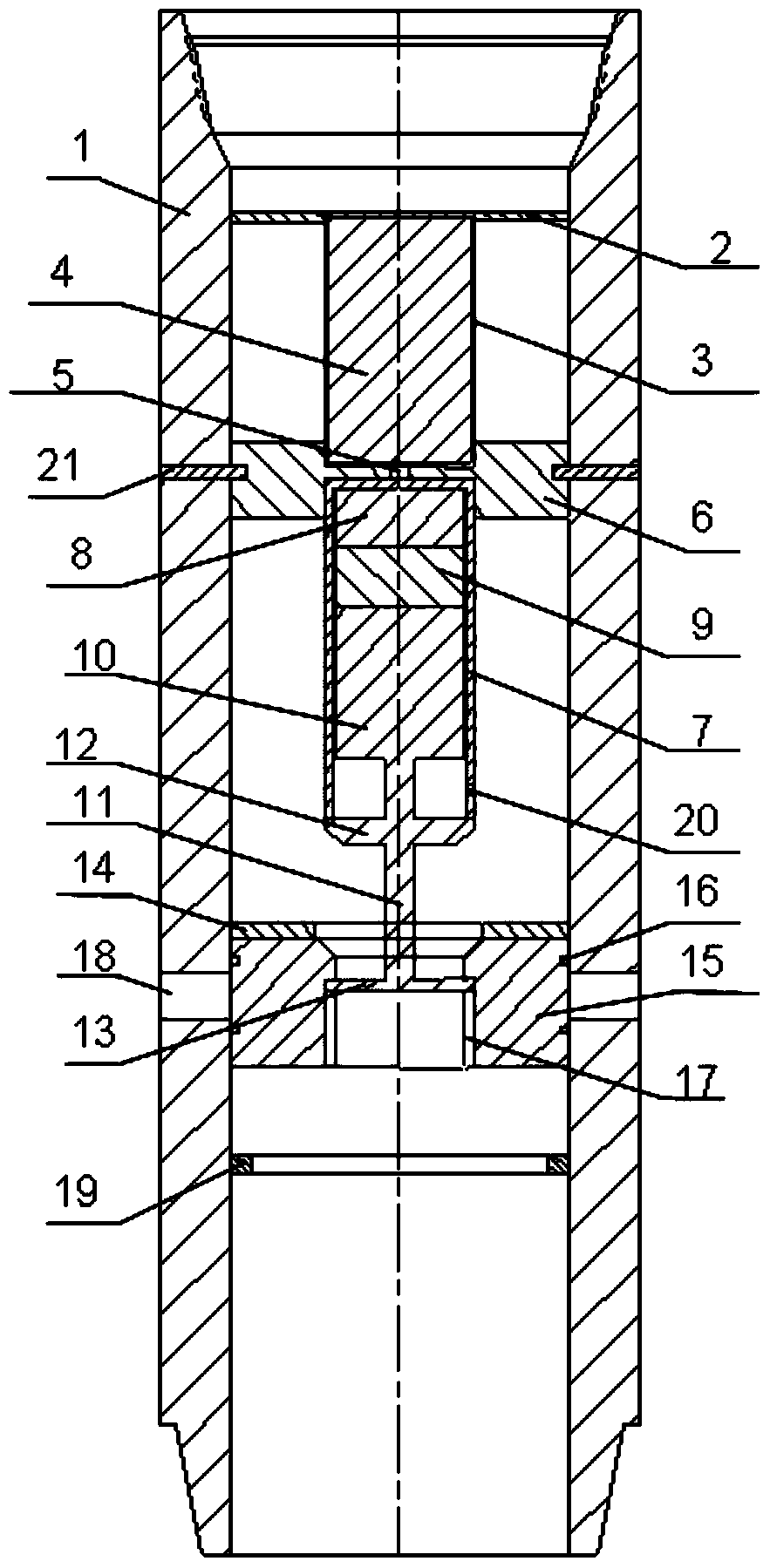

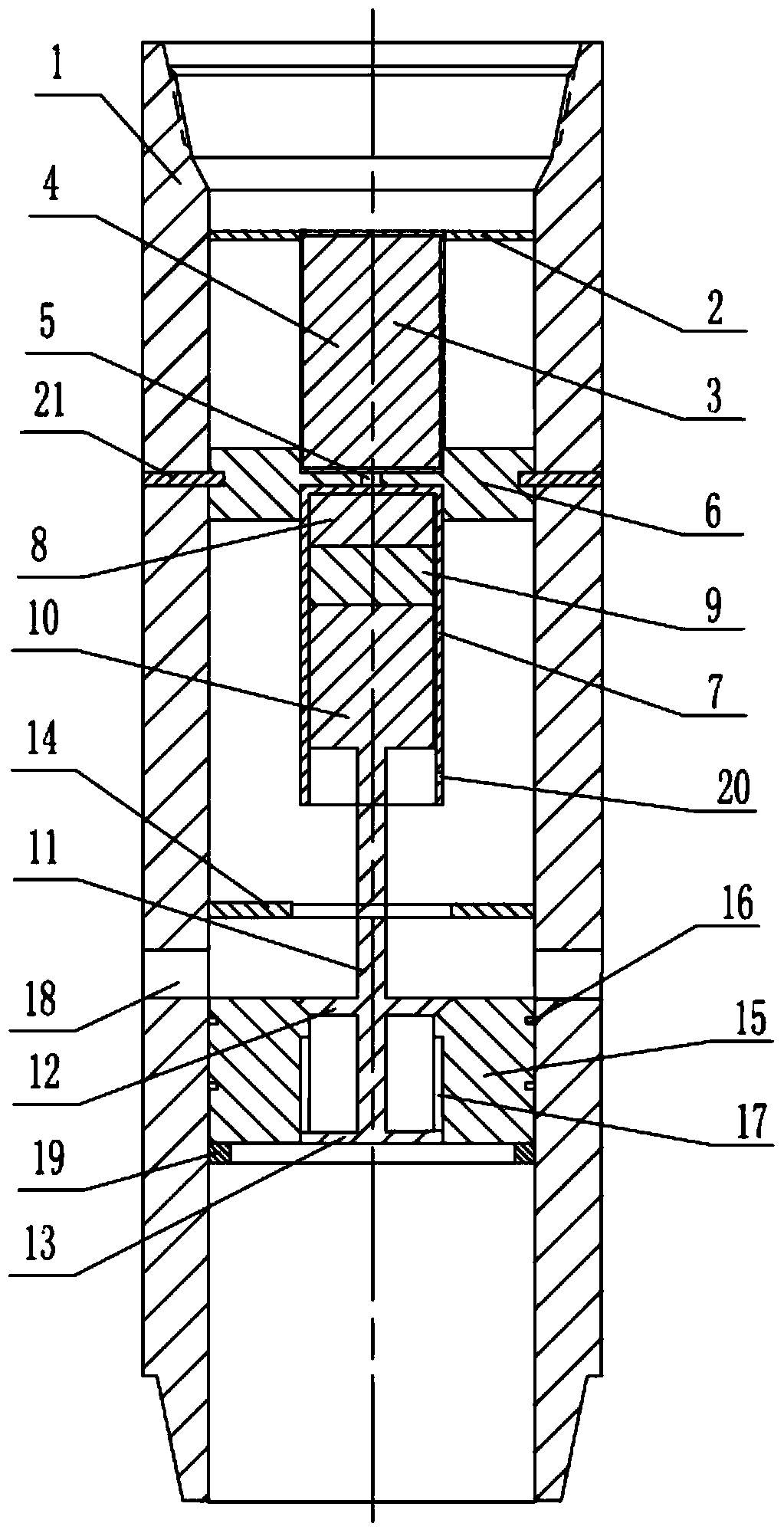

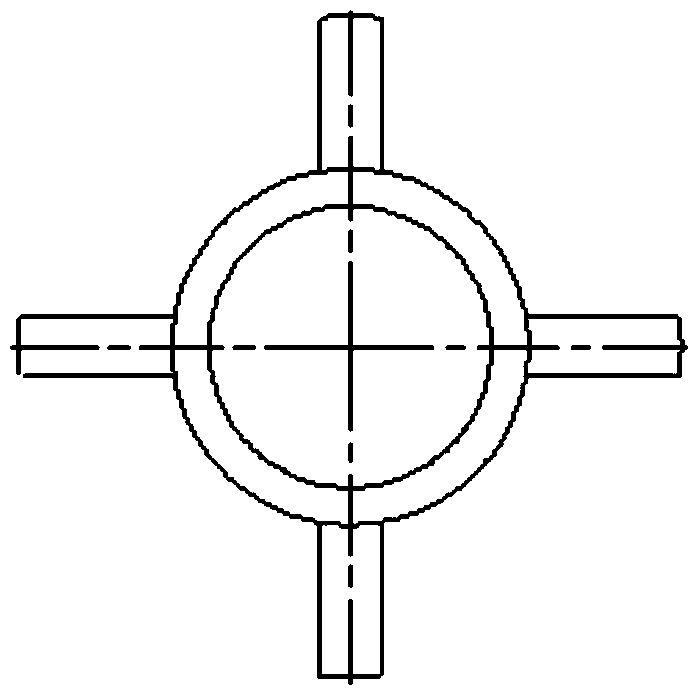

[0028] Such as figure 1 Shown is a specific embodiment of the MWD bypass valve of the present invention. In this embodiment, the bypass valve while drilling mainly includes four parts: a valve body 1 , a control unit, a power unit and an execution unit. Wherein, the valve body 1 is in the shape of a cylinder, and its upper and lower ends are provided with threads for connecting with drilling tools, and the middle part is a through hole. In addition, the control unit, power unit and execution unit are all installed in the valve body 1 .

[0029] In one embodiment, the power unit mainly includes a battery 4 , a battery can 3 , a motor 9 and a transmission assembly 10 . Wherein, the transmission assembly 10 is a screw transmission mechanism. The battery 4 is sealed in the battery can 3, the upper end of the battery can 3 has a centralizing blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com