Single spiral spin micro-seismic emitter

A technology of micro-seismic and transmitter, which is applied in drilling equipment, earth-moving drilling, driving device for drilling in wellbore, etc., can solve the problems of inability to meet the speed-up and development of drilling, increase the time of drilling down, and the working life is not long. , to achieve the effect of simple structure, low processing cost and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings and specific embodiments.

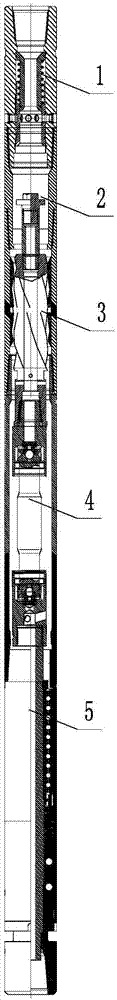

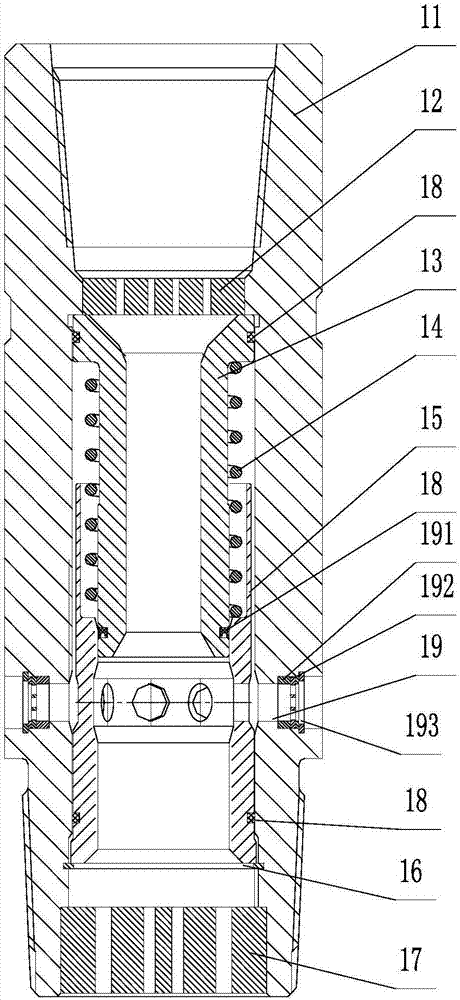

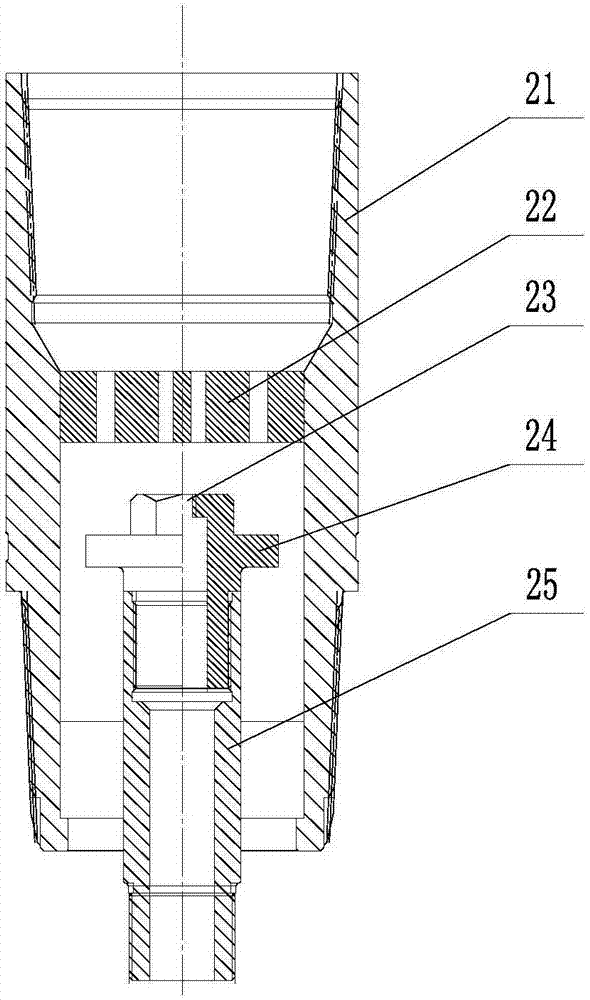

[0026] Such as figure 1 As shown, a single-screw rotary impact microseismic transmitter includes a filter bypass assembly 1, a filter safety assembly 2, a hydraulic assembly 3, and a transmission assembly connected by self-locking tapered threads from top to bottom. Into 4 and rotary micro seismic launcher assembly 5, the launcher uses drilling fluid to remove solid particles harmful to the motor in the filter bypass assembly 1. The filter safety assembly 2 ensures that the launcher can work safely and efficiently. At the same time, the nozzle split method is used to reduce the pressure drop of the motor. At the same time, the jet method assists in breaking the rock. The hydraulic assembly 3 converts the kinetic energy of the water into mechanical energy to form the eccentric movement of the hydraulic core 32 through the transmission assembly 4 The eccentric m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com