Combined control arm bushing with reinforcing mechanism

A strengthening mechanism and combined technology, which is applied to the cantilever mounted on the pivot, suspension, transportation and packaging, etc., can solve the large force between the body and the bushing of the control arm, and the rubber deformation of the original structural bushing Large size, unqualified durability of control arm bushing, etc., to achieve the effect of enhancing rigidity, increasing service life and reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

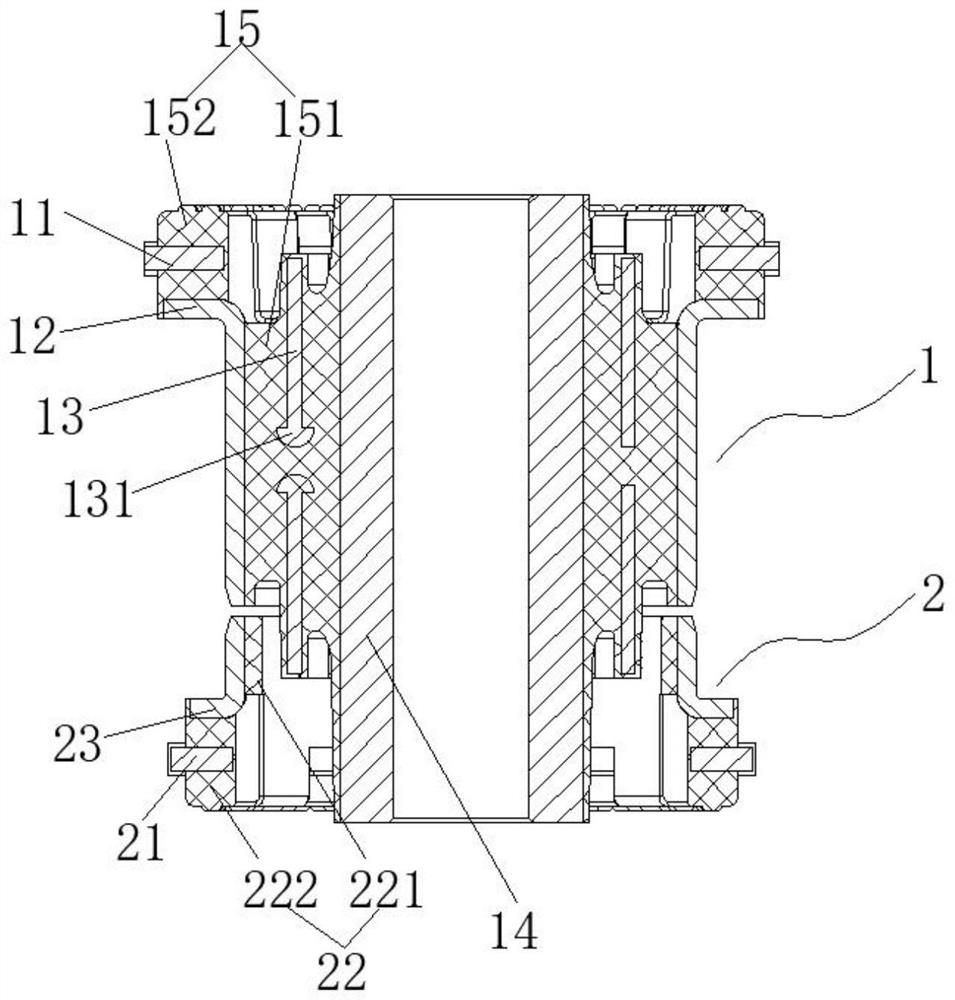

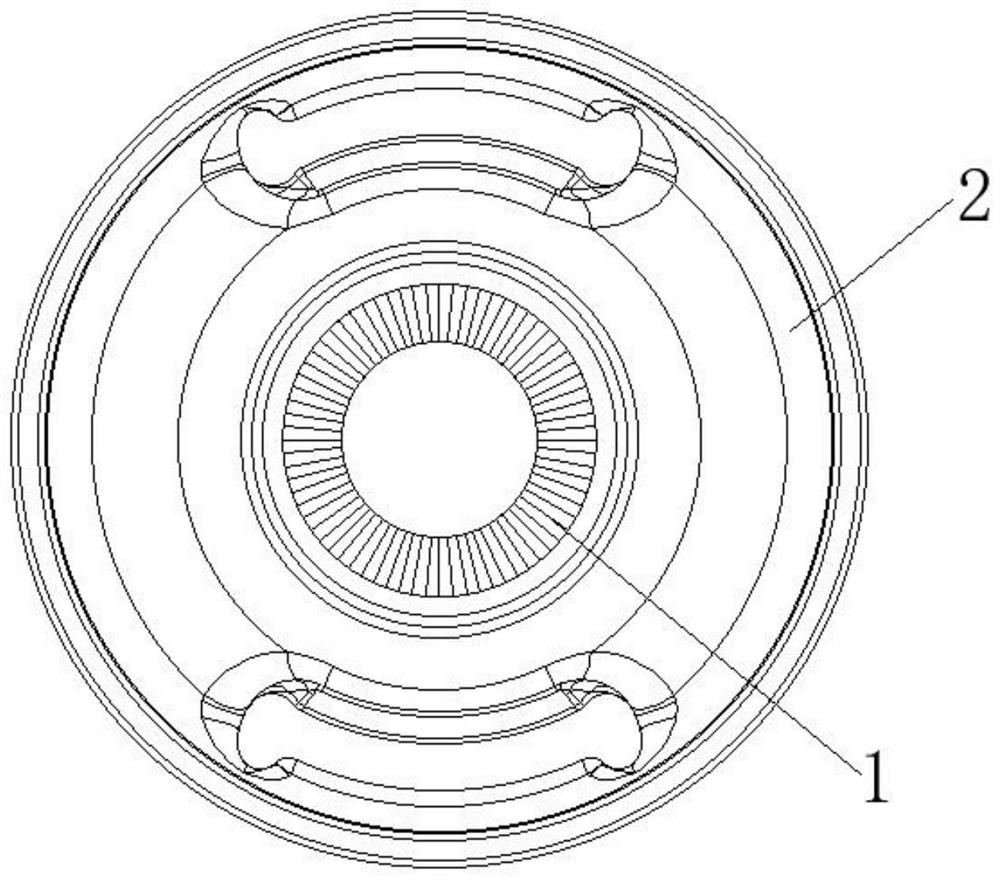

[0023] Such as figure 1 , figure 2 As shown, the combined control arm bushing with reinforcing mechanism includes a first component 1 and a second component 2, and the first component 1 is assembled with the second component 2;

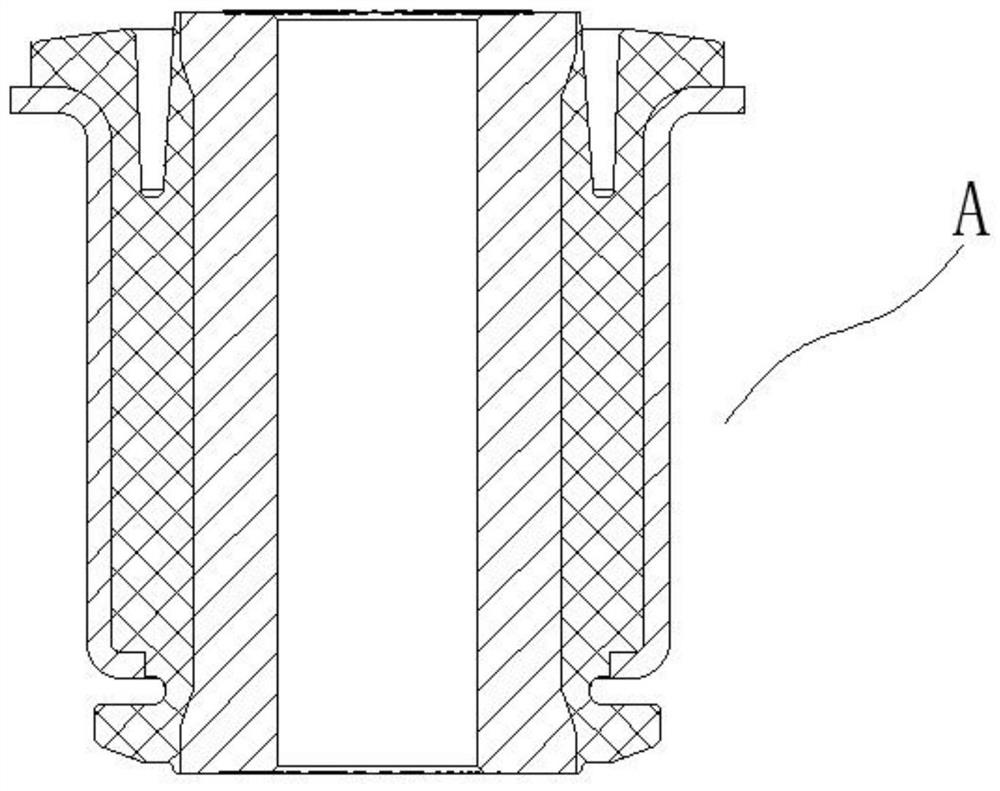

[0024] The first assembly 1 includes: a first outer casing 12, a first rubber layer 15, and an inner sleeve 14 disposed from the outer to the inner, and the first outer casing 12, the first rubber layer 15, and the inner sleeve 14 are provided as a cylindrical shape. The first rubber layer 15 includes a first long side 151 and a first short side 152, the first long side 151 and the first short side 152, which is set, and the first long side 151 The outer wall of the sleeve 142 is disposed at the first long side 151 away from the second component 2; the first short side 152 is provided with a first reinforcing gasket 11 for enhancing the first short side 152. The rigidity at the time of axial force; a medium sleeve 13 is provided in the first long side 151...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com