Method and system for controlling rotary tray flexible torque of electric drill

A torque control and turntable technology, applied in the automatic control system of drilling, drilling equipment, earthwork drilling, etc., can solve the problems of accelerating the damage of drilling tools, affecting the drilling speed, and fatigue of the drill string, so as to reduce the degree of fatigue damage, The effect of reducing the probability of downhole accidents and reducing the amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

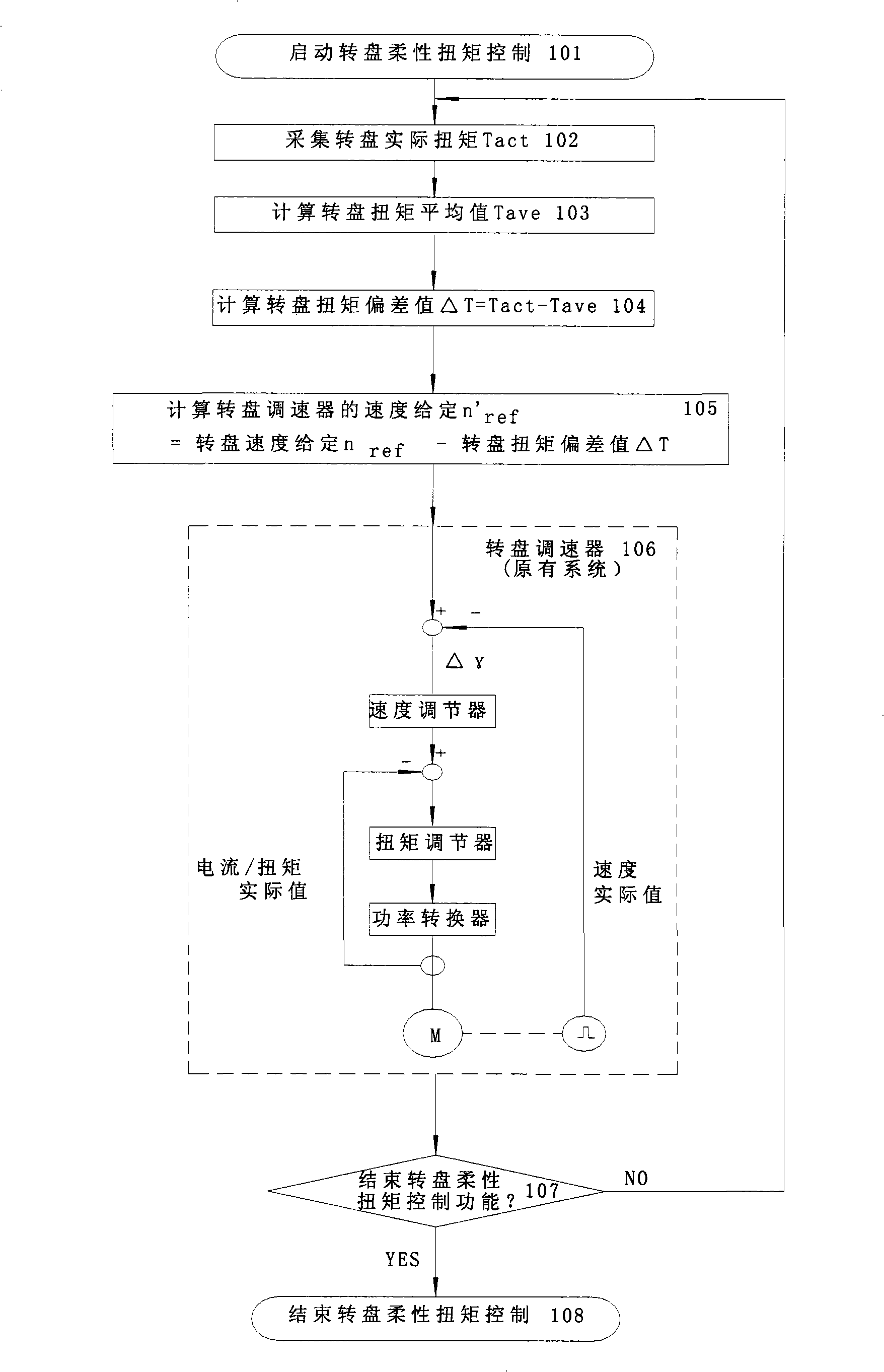

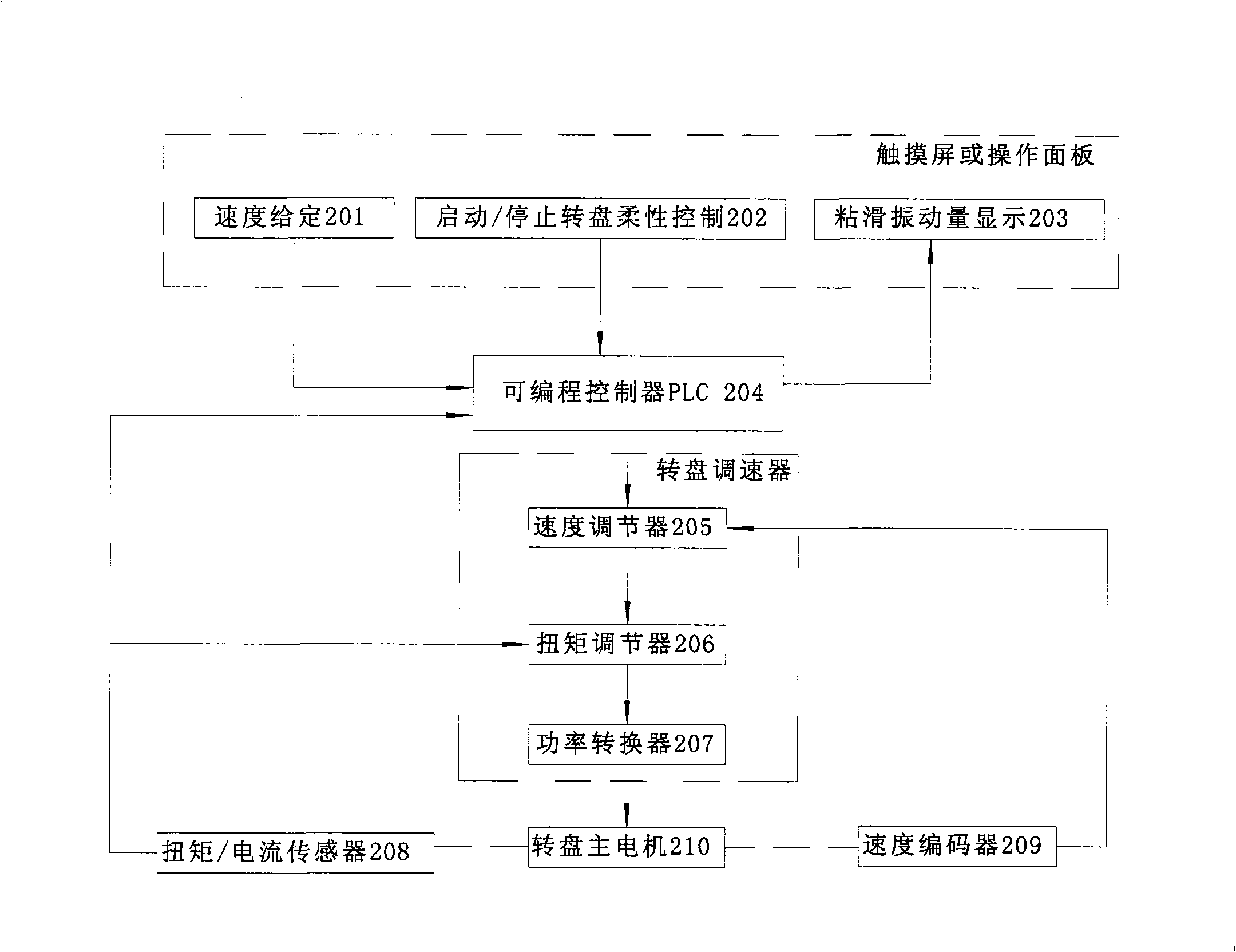

[0023] Such as figure 1 As shown, in step 101, the actual torque value of the turntable is collected by the torque sensor in real time, and transmitted to the programmable controller PLC, and the stick-slip vibration amount is calculated and displayed by the programmable controller PLC, and the stick-slip vibration amount=(Tmx-Tmin) / Tave, where: Tmax is the maximum value among the 15 recently collected torque value data, Tmin is the minimum value among the 15 recently collected torque value data, and Tave is the average value of the recently collected 15 torque value data. According to the characteristics of the geological bottom layer, generally when the display value of the stick-slip vibration on the touch screen is ≥ 15%, after 10 seconds, if the stick-slip vibration is still greater than 15%, the system will give a question of "whether to start the flexible torque control function of the turntable" information, the driller timely presses the start / stop turntable flexible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com