Variable inertia reaction flywheel

A technology of reactive flywheel and variable inertia, which is applied in auxiliary non-electrical speed/acceleration control, etc., can solve the problems of high energy consumption, difficult power supply of motors, and difficulty in detecting system mass distribution, and achieves the effect of simple structure and enlarged scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

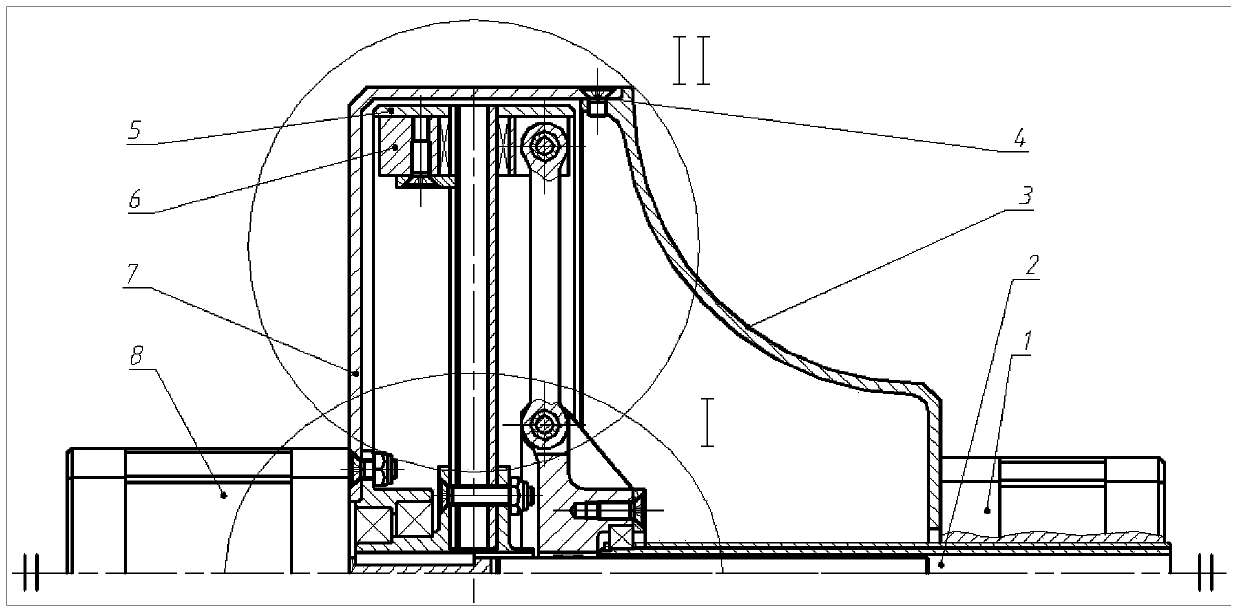

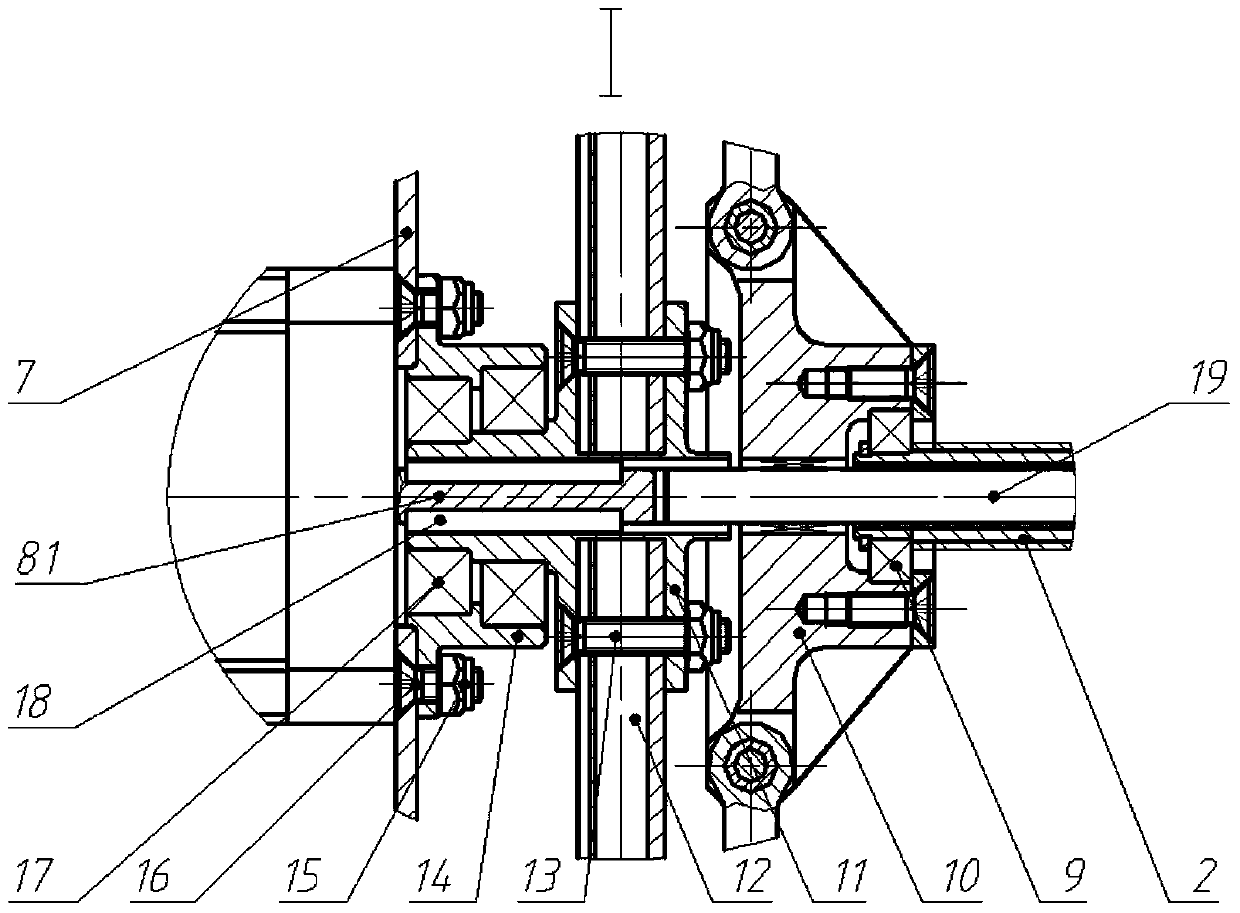

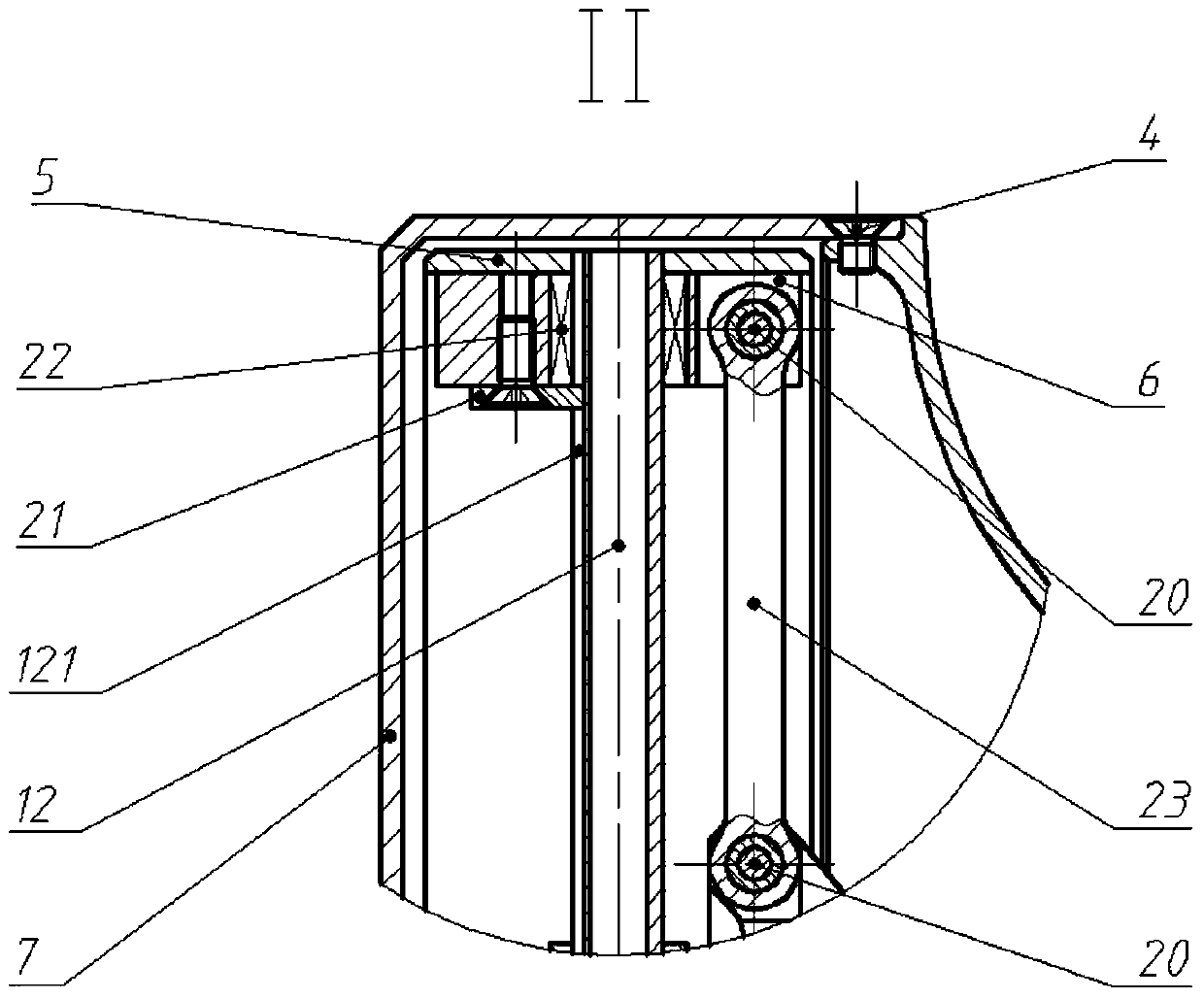

[0014] Such as figure 1 Shown is the structure diagram of the variable inertia reaction flywheel, figure 2 Partial enlarged view I for the variable inertia reaction flywheel, image 3 In order to change the inertia, use the flywheel to partially enlarge the view II. The variable inertia reaction flywheel includes the lead screw motor 1, the lead screw 2, the right housing 3, the screw a4, the wheel outer ring 5, the counterweight 6, the left housing 7, the drive Motor 8, deep groove ball bearing a9, slider 10, flywheel shaft 11, guide rod 12, screw b13, support 14, self-locking nut 15, screw c16, deep groove ball bearing b17, flat key 18, guide rod 19, Pin shaft 20, anti-twist block 21, sliding bearing 22 and connecting rod 23, wherein drive motor 8 is provided with drive motor shaft 81, and guide bar 12 is provided with anti-twist groove 121; The ring 5 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com