Piston type speed controller

A speed controller, piston-type technology, applied in auxiliary non-electrical speed/acceleration control, shock absorber, shock absorber, etc., can solve the problems of high manufacturing cost and difficult parts processing, and achieve low manufacturing cost , the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

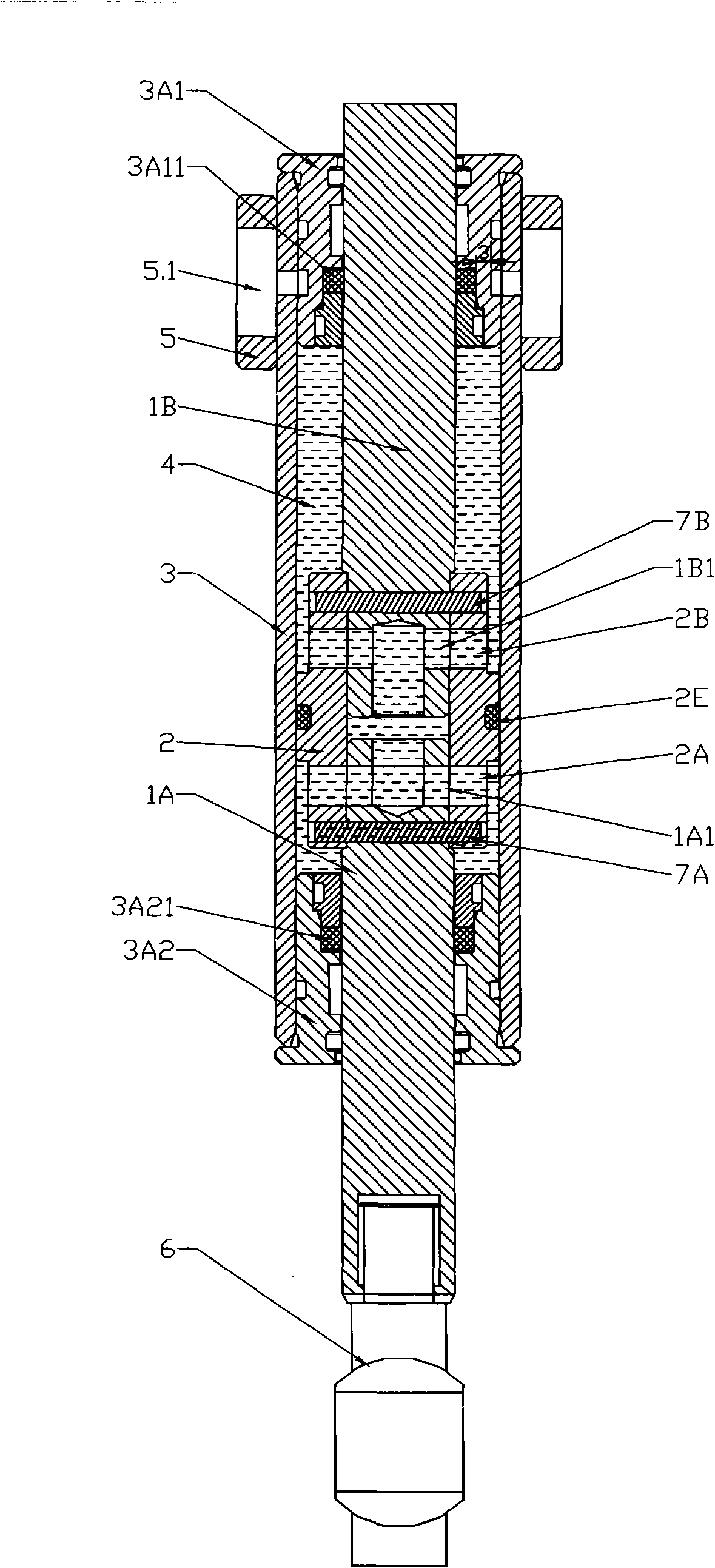

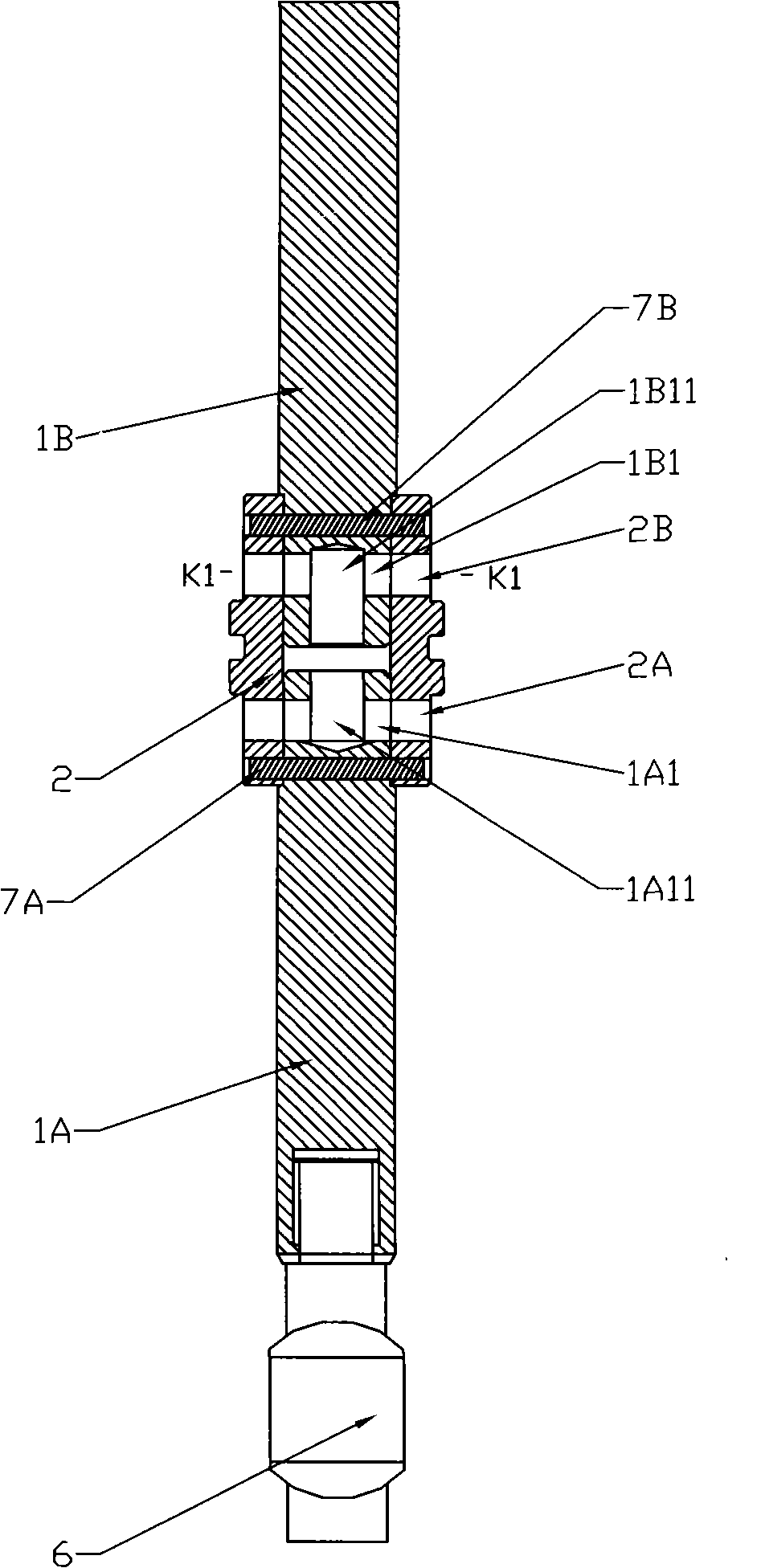

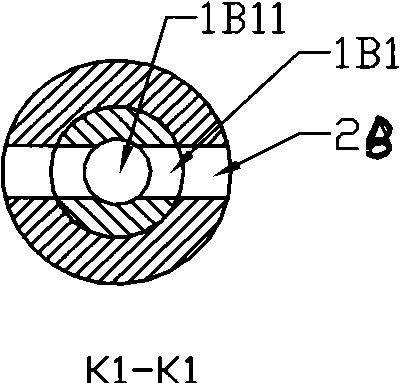

[0018] figure 1 , figure 2 , image 3 is a structural schematic diagram of the first embodiment of the present invention, figure 1 is a schematic diagram of the structure of this embodiment, figure 2 is a partial view of this embodiment, image 3 yes figure 2 The sectional view of the figure shows that, unlike the first embodiment, the piston speed controller of this embodiment mainly includes a flow medium 4, a piston 2, piston rods 1A and 1B, a piston cylinder 3, and a piston cylinder end 3A1 and 3A2, fixed seat 5, rod end connector 6 and seals 3A11, 3A21, 2E, seals 2E are arranged on piston 2, and piston 2 is connected and fixed to piston rods 1A and 1B respectively through pin shafts 7A and 7B, The piston cylinder 3 seals the flow medium 4 inside the cylinder body 3 through the two piston cylinder ends 3A1 and 3A2 arranged at both ends, the piston 2 is arranged inside the piston cylinder 3 and the piston rods 1A and 1B pass through the ends of the piston cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com