Dynamic performance and active damping method in web winding machine tension control system

A tension control and control system technology, applied in the field of tension systems, can solve problems such as crossover frequency limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]Embodiments of the present invention relate to systems and methods for controlling tension in a continuous web of material, and more particularly, to systems and methods for controlling tension in a continuous web of material in which a System damping is improved and thus better tension response is achieved. The primary and secondary drive units in the web winding system operate in speed mode and modified torque-regulated closed-loop tension control mode, respectively, and the speed feedback loop is integrated into the torque-regulated closed-loop tension control mode to improve the system Damping and enabling faster response times when controlling tension in a continuous web of material.

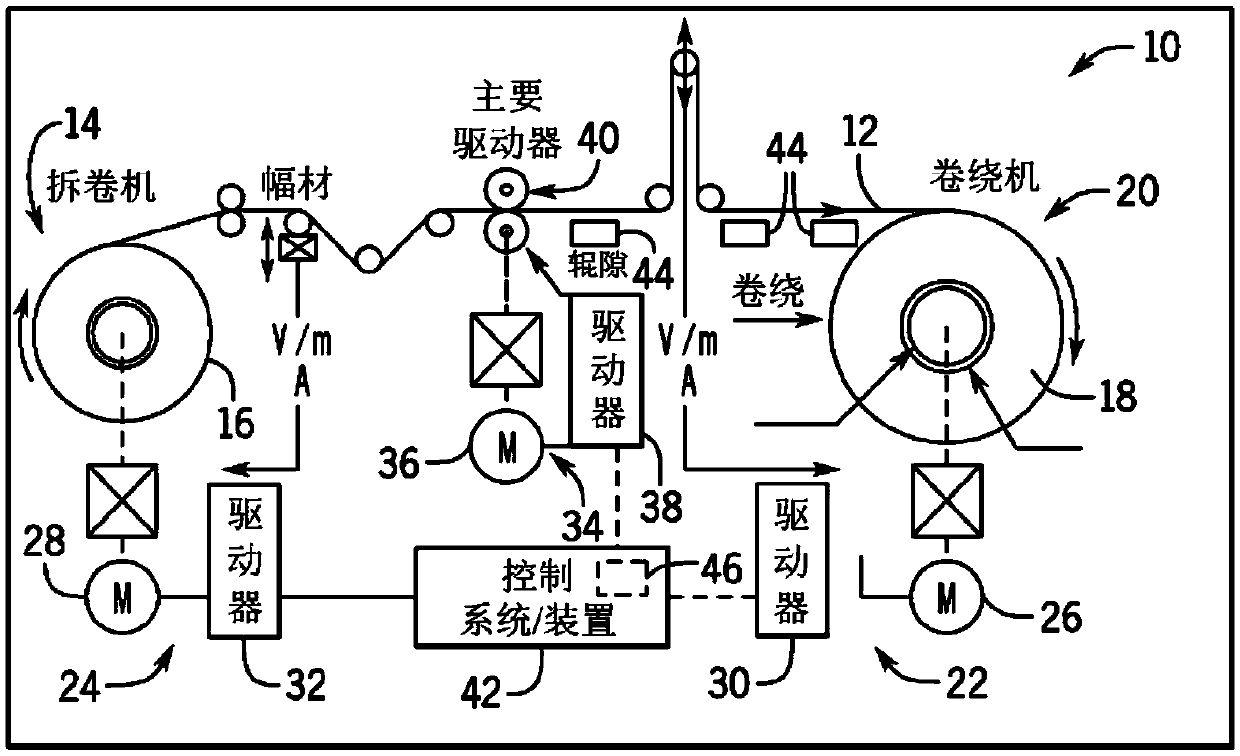

[0027] figure 2 is a diagram showing a system 10 for winding and unwinding a product film or web material, ie, a "web winder system", such winding and unwinding being performed in a tension-controlled manner to ensure Integrity of the web material 12 . figure 2 The system can be, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com