Intelligent control system for automatic cutting formation of tunneling

An intelligent control system and automatic technology, applied in cutting machinery, electrical program control, auxiliary non-electrical speed/acceleration control, etc., can solve the problem that the automatic control system of the roadheader cannot be realized at the same time and cannot guarantee the constant power operation of the cutting motor. , It is impossible to realize the automatic stepless speed regulation of the cutting head, etc., to achieve the effect of convenient execution of commands and timely modification, convenient control of parameter values, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

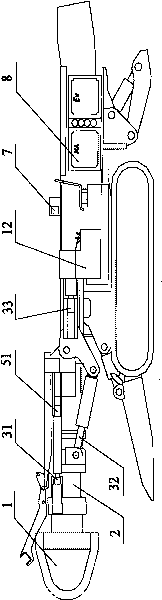

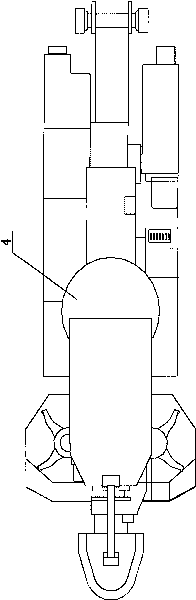

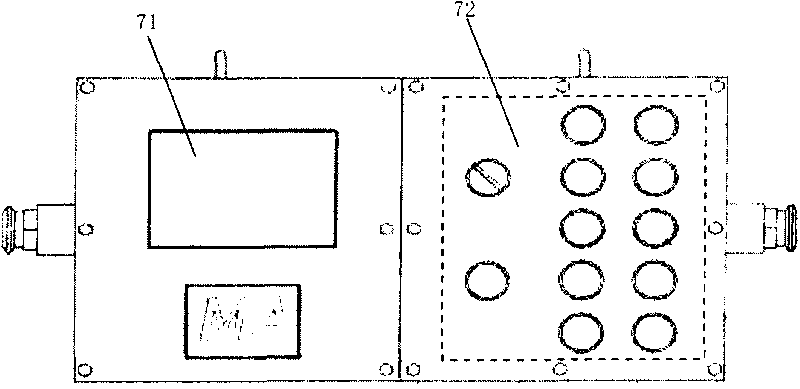

[0088] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, its specific implementation, structure, Features and their functions are described in detail below.

[0089] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the drawings. Through the description of specific implementation methods, the technical means and effects of the present invention to achieve the intended purpose can be understood more deeply and specifically, but the attached drawings are only for reference and description, and are not used to explain the present invention limit.

[0090] The intelligent control system for driving automatic cutting and forming in a preferred embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com