Optimal distribution method of uniaxial batch reaction flywheel torque based on angular momentum margin

A reaction flywheel, optimized distribution technology, applied in the torque distribution of flywheel, torque optimization field of single-axis reaction flywheel, can solve the problem of flywheel torque saturation, low efficiency, complex solution of quadratic programming method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

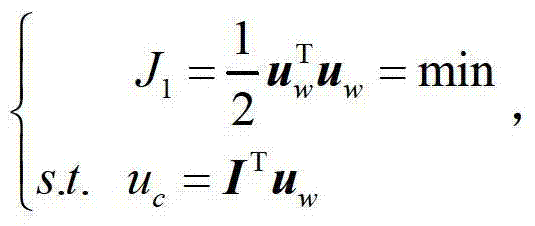

[0040] 1. Establish a mathematical model for torque distribution of uniaxial batch reaction flywheels. Assuming that there are n reaction flywheels installed on a certain axis of the aircraft, the installation matrix of the flywheel set can be written as The desired torque of the system on this axis is denoted as u c , the command torque assigned to each flywheel is denoted as Then the relationship between the expected torque and the command torque should satisfy u c = I T u w , and this formula is also the constraint condition of the derivation optimization problem.

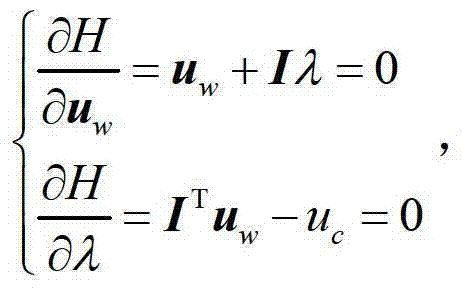

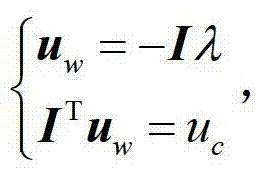

[0041] 2. Deduce the energy optimal allocation method. Since the energy consumption of the flywheel system is closely related to the output torque of each reaction flywheel, the following energy index function is constructed by using the flywheel torque vector Then the energy optimal allocation strategy can be expressed as the following optimization problem:

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com