Load torque control system and load torque control method

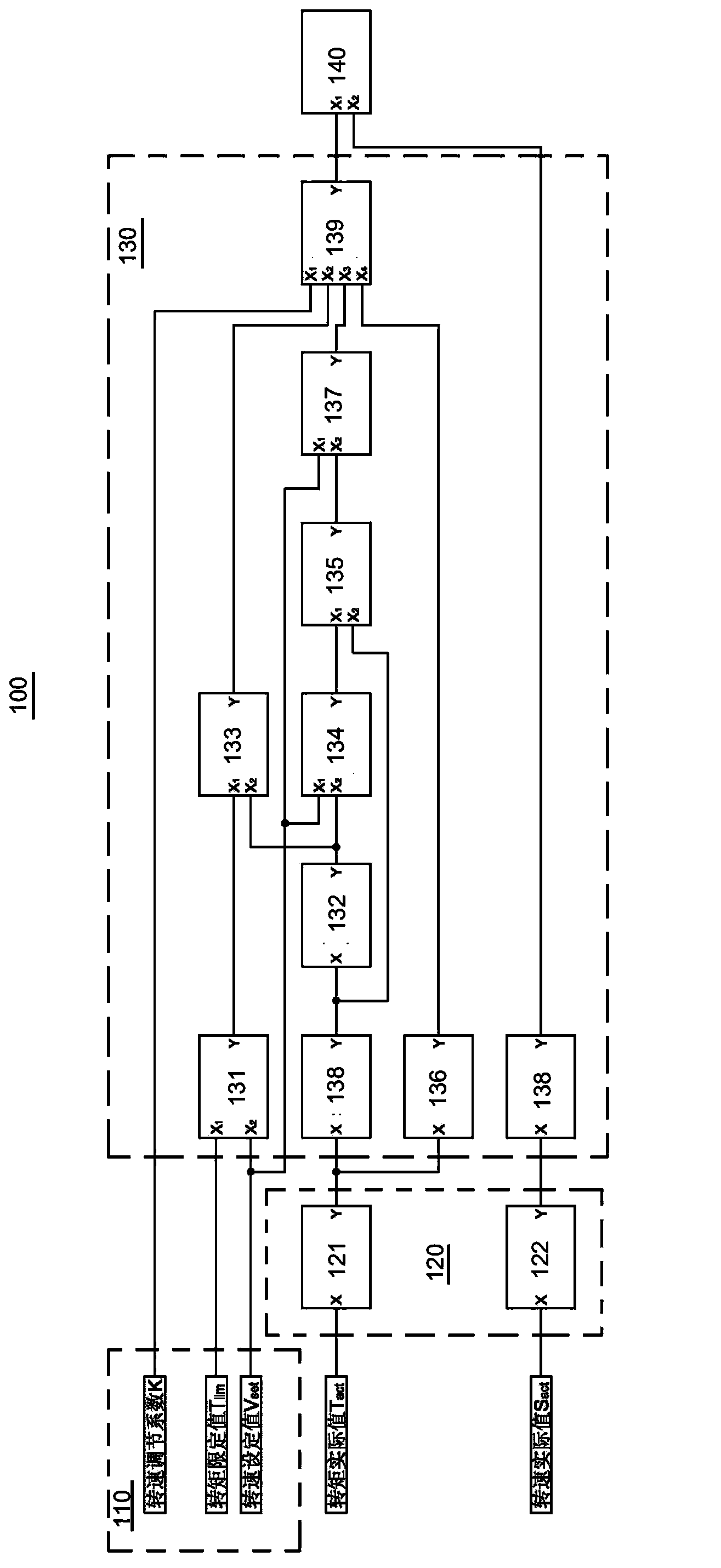

A load torque and control system technology, which is applied in the load torque control system to control the load torque of long shafting or elastic load mechanical equipment, and can solve problems such as twisting, mechanical equipment wear, and transverse cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the purpose, technical solution and advantages of the present invention clearer, the following examples are given to further describe the present invention in detail. In the following embodiments, the present invention is described by taking drilling as an example, but it should be understood that the present invention is by no means limited to the application of such drilling, but can be applied to any long shaft system.

[0045] For example, in the process of oil drilling, the drill bit is several thousand meters underground, and the middle is connected by the drill pipe, which is very elastic. Due to the reason of the formation, the drill bit may be stuck and cause a stall. Due to the length and elasticity of the drill pipe, so This problem cannot be found immediately on the ground, and the top drive motor will continue to rotate at the set speed; this part of the energy is absorbed and stored by the drill pipe, and will eventually be transmitted to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com