Brushless DC motor direct torque control system and control method

A direct torque control, brushed DC motor technology, applied in control systems, vector control systems, motor generator control and other directions, can solve problems such as complex systems and unfavorable engineering implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

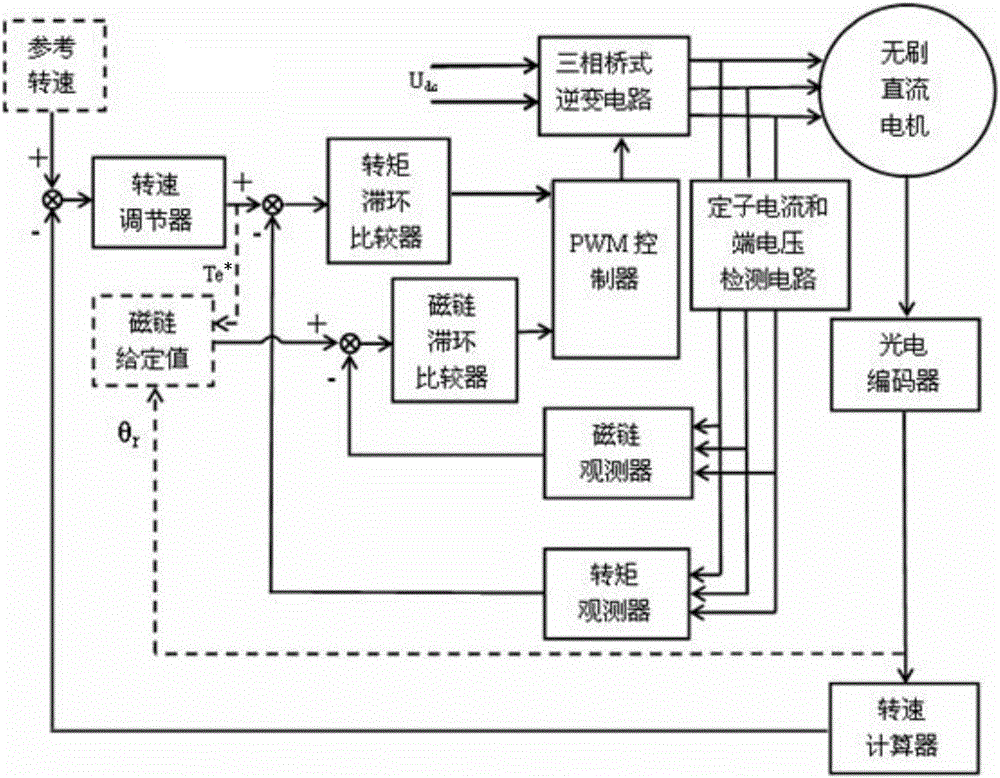

[0103] Such as figure 1 As shown, a brushless DC motor direct torque control system, including photoelectric encoder, stator current and terminal voltage detection circuit, speed calculator, speed error comparator, speed regulator, flux observer, flux error comparison device, flux hysteresis comparator, torque observer, torque error comparator, torque hysteresis comparator, PWM controller and three-phase bridge inverter circuit, the photoelectric encoder is installed in the brushless DC motor On the rotor, it is used to collect the position information of the rotor. The output end of the photoelectric encoder is connected to the input end of the speed calculator, the negative input end of the speed error comparator is connected to the output end of the speed comparator, and the positive input end of the speed error comparator Input the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com