Parallel-in converter for directly-driving wind power generation system

A technology of converters and power grids, which is applied in the direction of conversion equipment for intermediate conversion to DC, conversion of AC power input to AC power output, electrical components, etc., which can solve the problems that hinder the promotion of direct-drive wind turbines, and the price is expensive , Difficulty in manufacturing energy storage inductors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

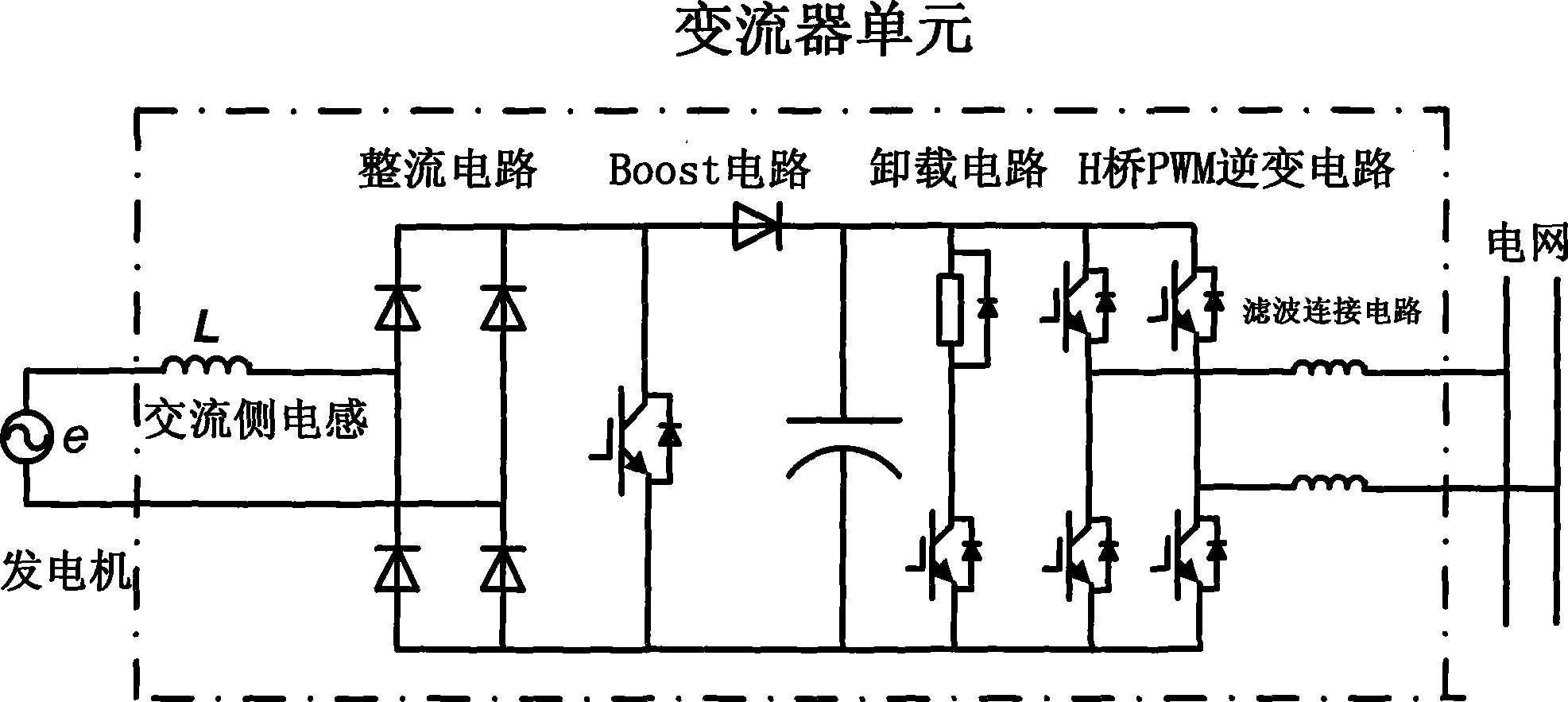

[0045] Example 1: 20kW direct drive wind power converter (diode rectification mode)

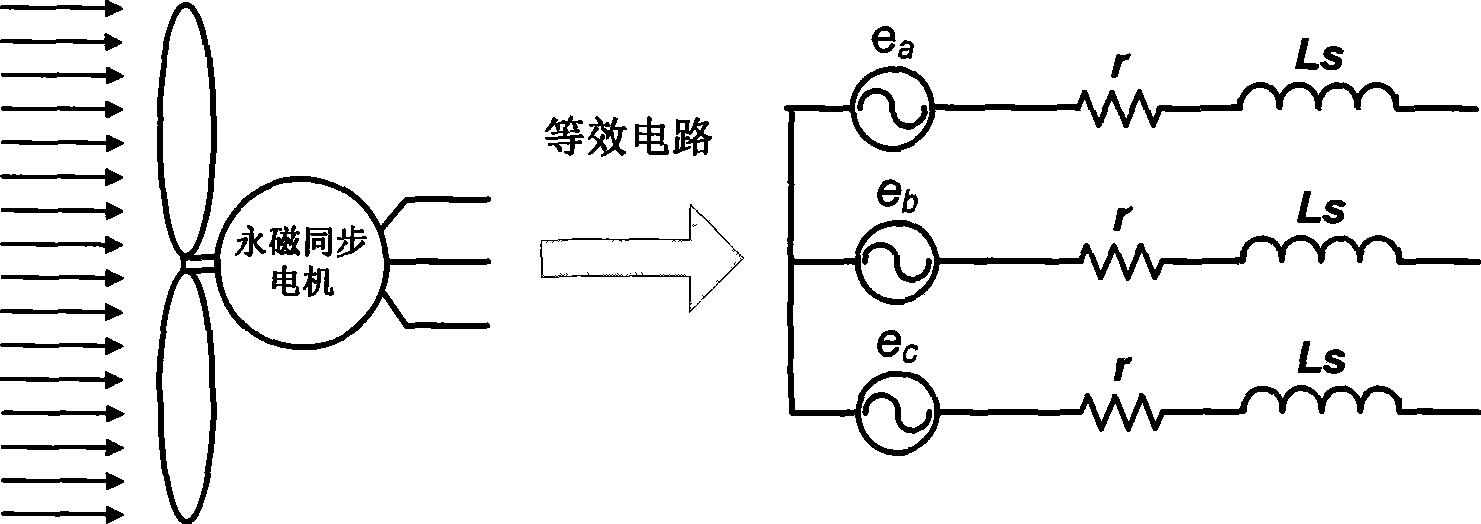

[0046] as attached Figure 11 The direct-drive wind power generation system composed of 20kW converter is shown. The input side of the converter works in diode rectification mode. The wind turbine directly drives the three-phase permanent magnet synchronous generator, and its output terminal is connected to the three-phase diode full bridge Rectifier circuit, the output terminal of the rectifier circuit is connected with the power switching device (IGBT or IGCT, etc.) The AC side of the inverter is connected to the three-phase grid through an LCL filter connection circuit and a transformer. The rated power of the permanent magnet synchronous generator in the system is 20kW, the equivalent inductance of the motor stator winding is 7.5mH, the rectification circuit adopts the three-phase rectification module of Fuji 1600V / 100A, and the boost circuit and inverter circuit adopt Mitsubishi CLA ser...

Embodiment 2

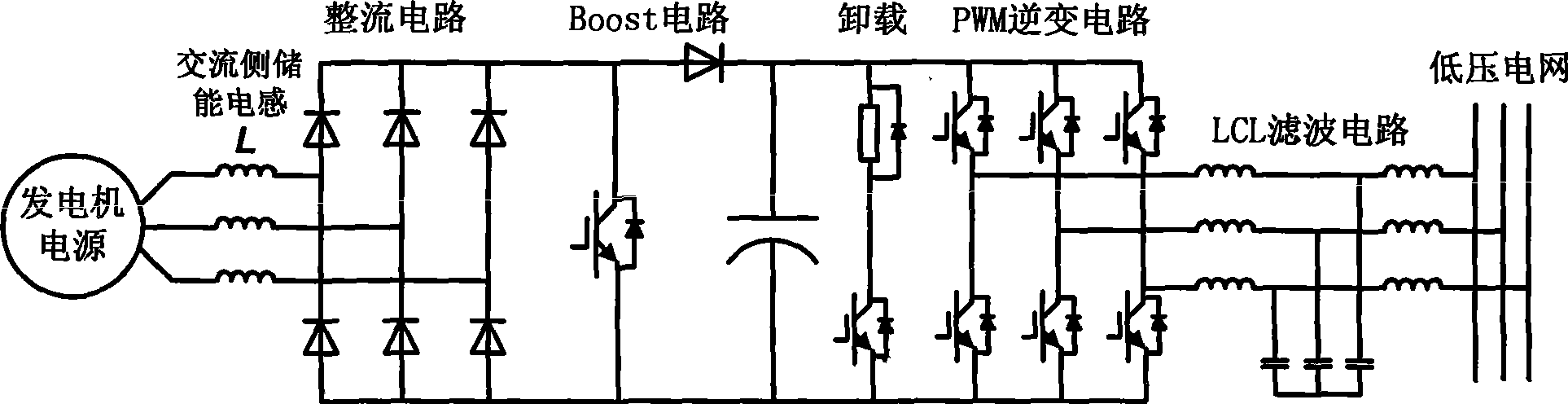

[0049] Embodiment 2: 30kW~500kW direct drive wind power converter (diode rectification mode)

[0050] On the basis of the first embodiment, by selecting large-capacity power electronic devices, the rectification side adopts the attached Figure 5 The multiple structure of the Boost circuit shown in the inverter side adopts the attached Image 6 The parallel structure of the power devices shown can increase the capacity of the converter device, as shown in the attached Figure 12 And attached Figure 13 shown. attached Figure 12 The structure of multiple Boost circuits is adopted on the rectification side; Figure 13 On the basis of multiple Boost circuits on the rectifier side, devices are connected in parallel on the inverter side. After adopting this scheme, the capacity of the converter device can reach 500kW.

Embodiment 3

[0051] Embodiment 3: 1.5MW direct drive wind power converter (diode rectification mode)

[0052] attached Figure 14 And attached Figure 15 Shown is a schematic structural diagram of a 1.5MW direct-drive wind power generation system. attached Figure 14 The medium converter is composed of four units, and each converter unit contains a Boost circuit; the stator winding of the 1.5MW permanent magnet synchronous generator is designed as 12 phases, and every 3 phases are divided into groups and connected to four transformers respectively. input side of the converter unit. Each converter unit includes an independent rectifier circuit, Boost circuit, DC bus capacitor and H-bridge inverter circuit. Each converter unit is in parallel structure, connected together by H-bridge cascading at the output end, and then through The LCL filter connection circuit and transformer are connected to the grid. attached Figure 15 The medium converter is composed of three units, and each conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com