System and method for on-line detection of operating junction temperature of IGBT module

A detection system, a technology for working junction temperature, applied in the direction of single semiconductor device testing, etc., can solve the problems of difficult extraction, inapplicable IGBT module online monitoring, delay in junction temperature monitoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

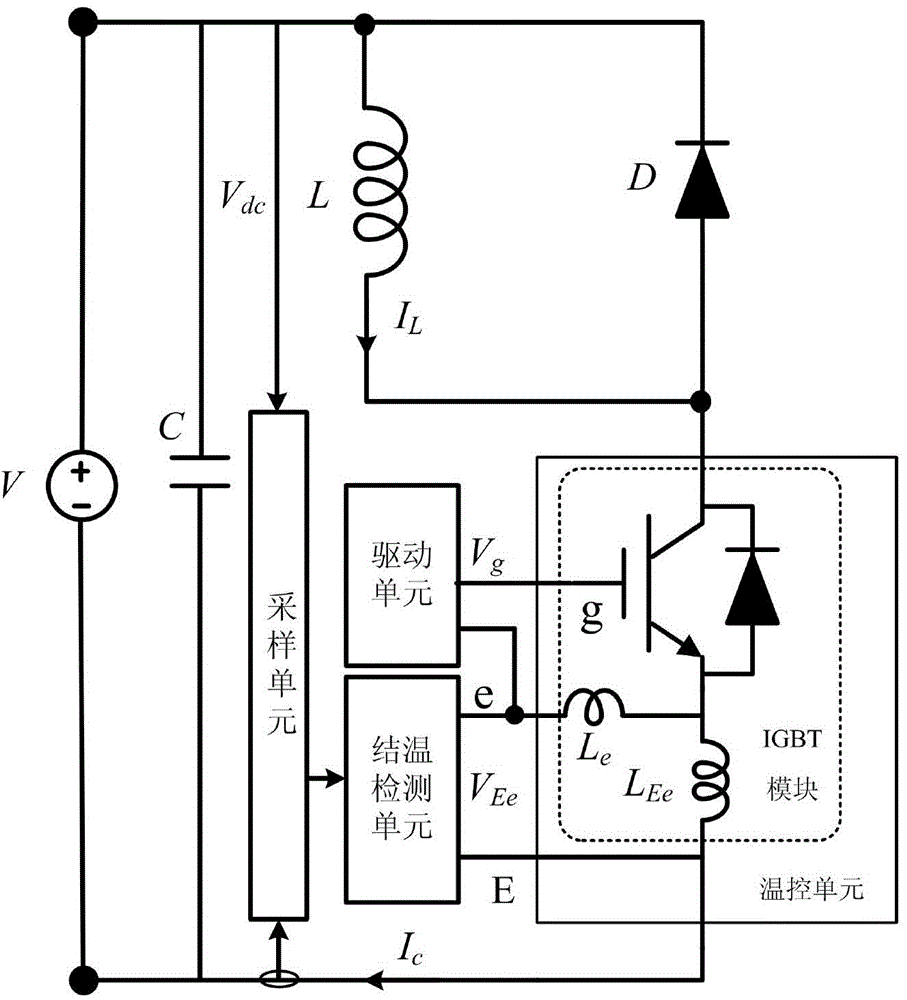

[0044] figure 1 The circuit structure of the online test system for the IGBT module working junction temperature of the inductive load is shown. The test system includes a temperature control unit, a drive unit, a sampling unit, a DC power supply V, a DC capacitor group C, a load inductance L, a high-power IGBT module, a high-power diode module D and a junction temperature detection unit, of which: power diode module D The cathode of the load inductor L is connected to the positive pole of the DC capacitor bank C and the positive pole of the DC power supply V, one end of the load inductance L is connected to the power collector terminal of the high-power IGBT module, and the other end is connected to the positive pole of the DC capacitor bank C and the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com