Injection moulding machine servo energy-saving control system

An energy-saving control system and injection molding machine technology, applied in the field of servo energy-saving control systems, can solve the problems of poor control effect, poor applicability, and poor energy-saving effect, and achieve the effects of reduced heat generation, good applicability, and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

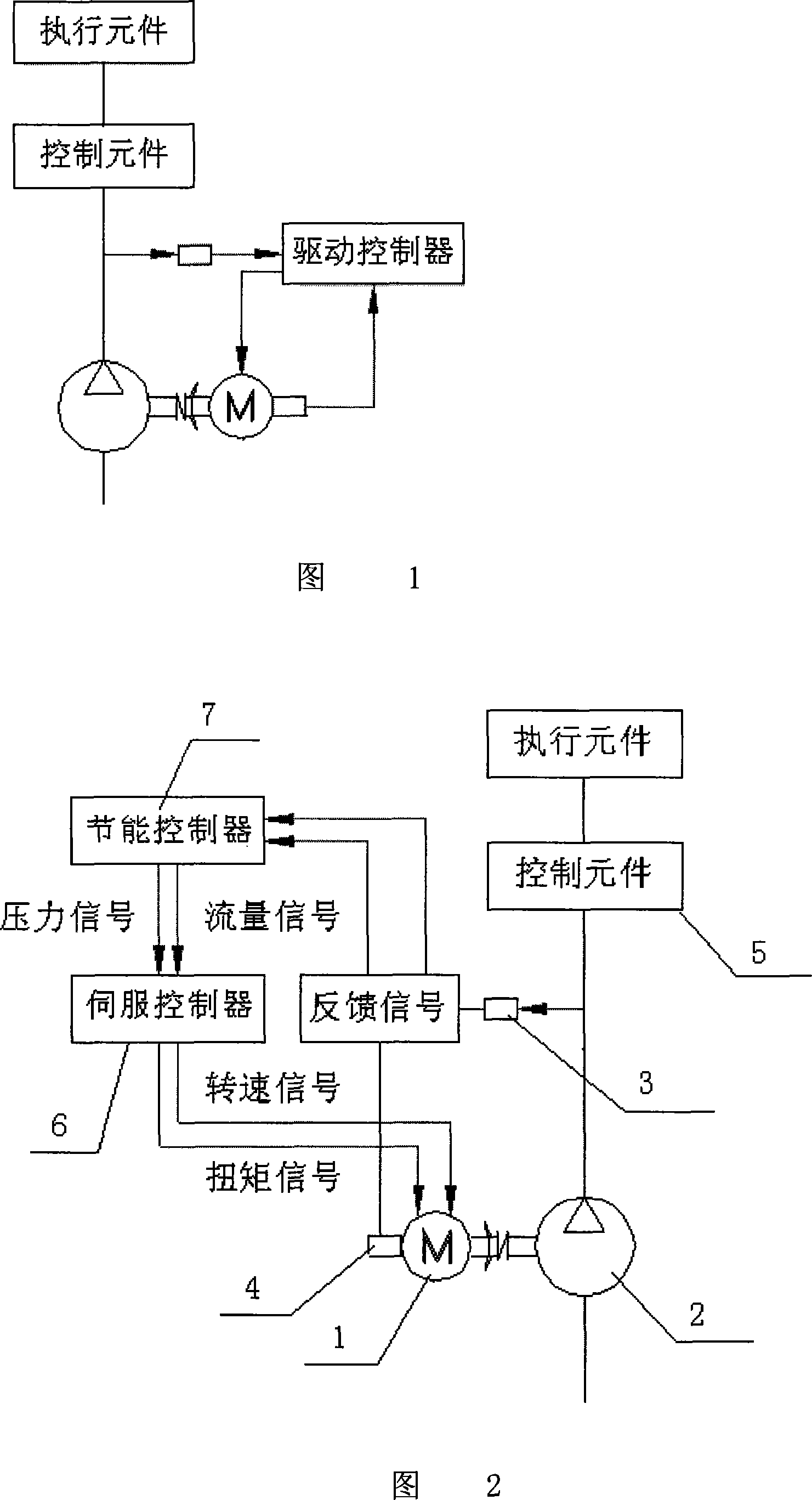

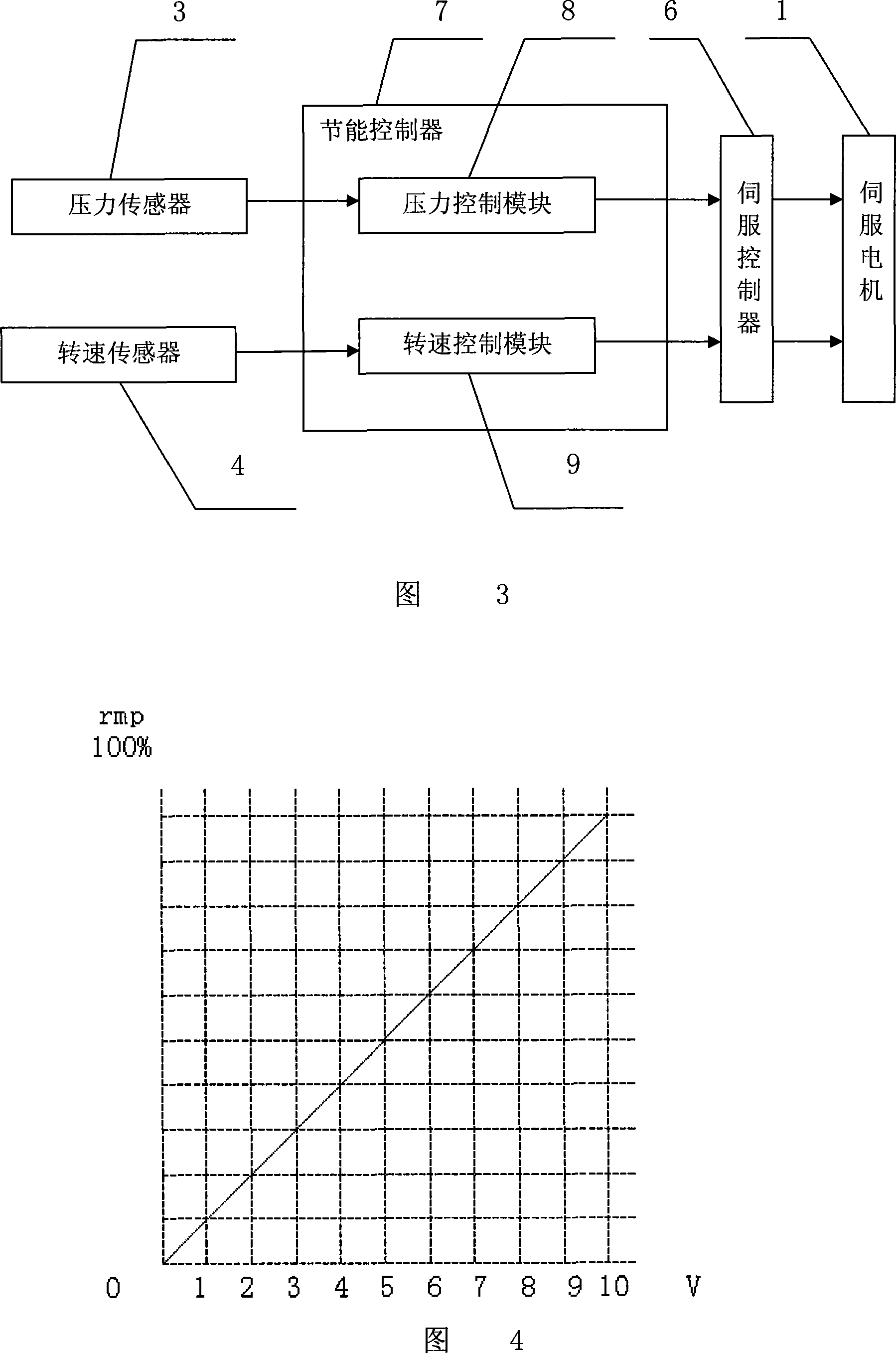

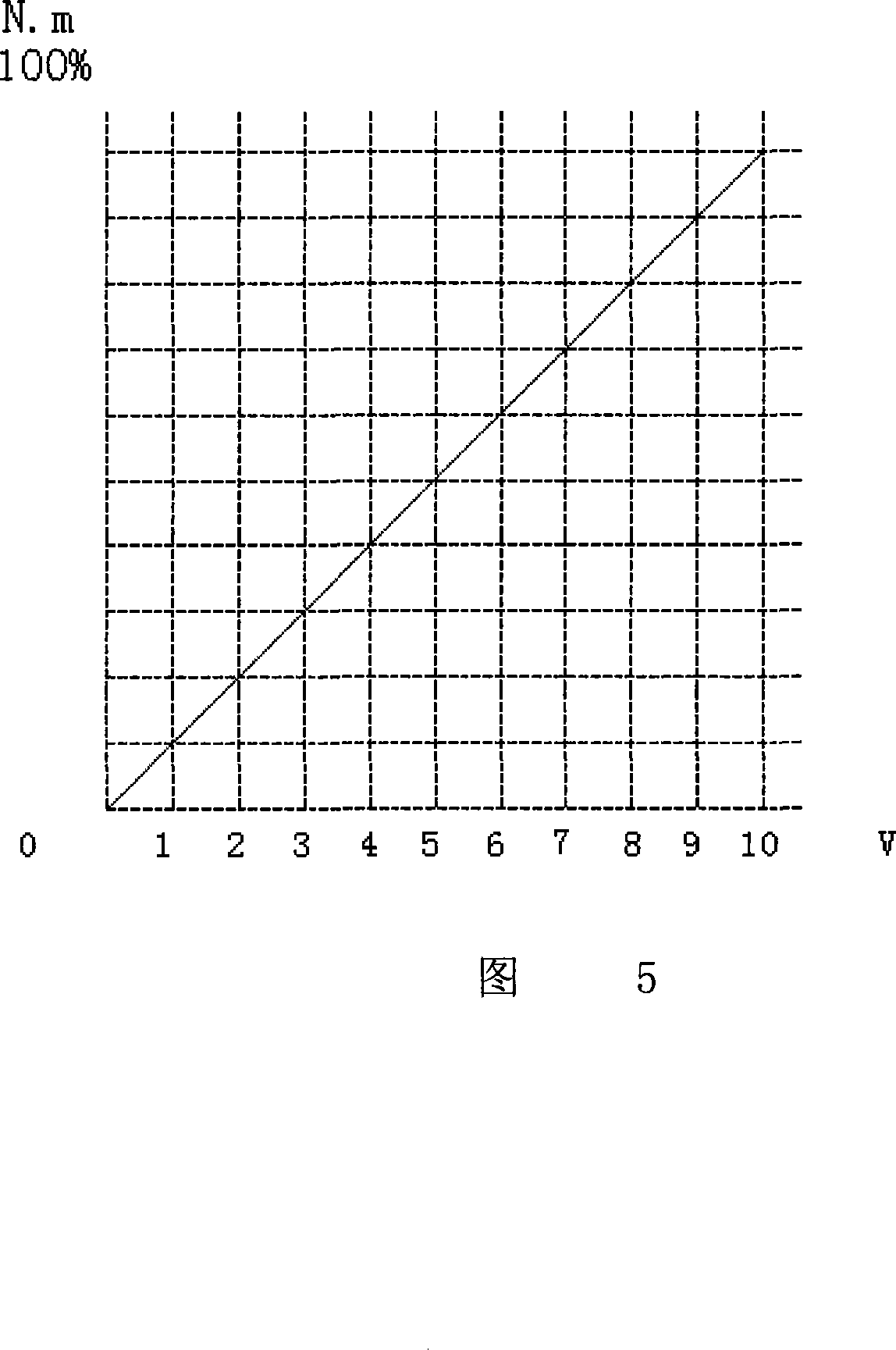

[0020] Referring to Figures 2 to 5, a servo energy-saving control system for an injection molding machine includes a servo motor 1, a quantitative oil pump 2 for providing pressure to a hydraulic system, a pressure detection sensor 3, a rotational speed sensor 4, and a control element 5. The servo motor 1 With a servo controller 6, the output of the servo motor 1 is connected to the quantitative oil pump 2, the output of the quantitative oil pump 2 is connected to the control element 5, the pressure detection sensor 3 is installed on the oil circuit output by the quantitative oil pump, and the rotational speed The sensor 4 is installed in the servo motor 1, and the control system also includes an energy-saving controller 7 for realizing automatic closed-loop adjustment of pressure and flow, and the output of the pressure detection sensor 3 and the rotational speed senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com