Medium/low-temperature core-shell denitration catalyst and preparation method and application thereof

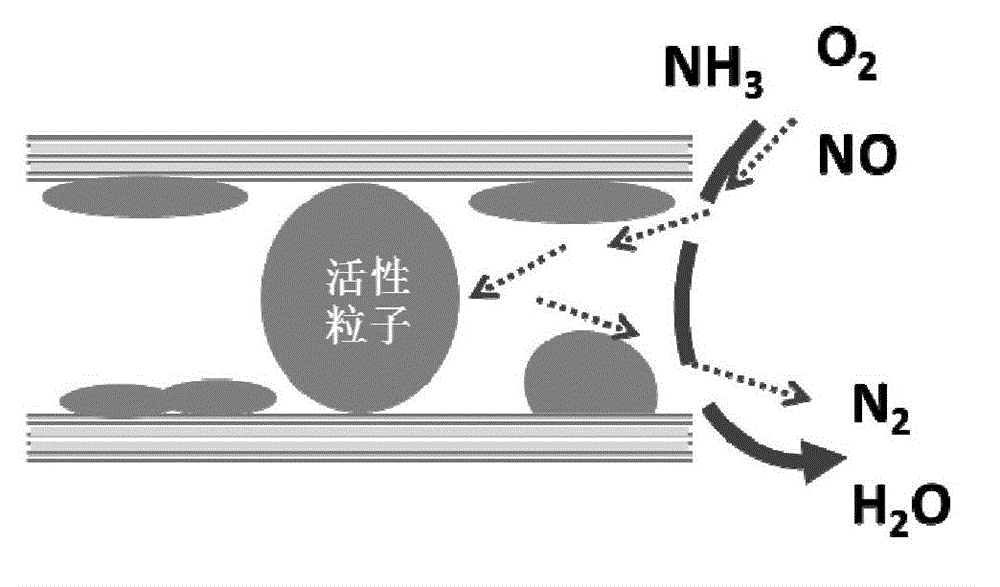

A denitrification catalyst, core-shell type technology, applied in the field of medium and low temperature core-shell type denitrification catalyst and its preparation, can solve the problems of solid poison poisoning, etc., and achieve the effect of maintaining stability, good selectivity, and simple and effective preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

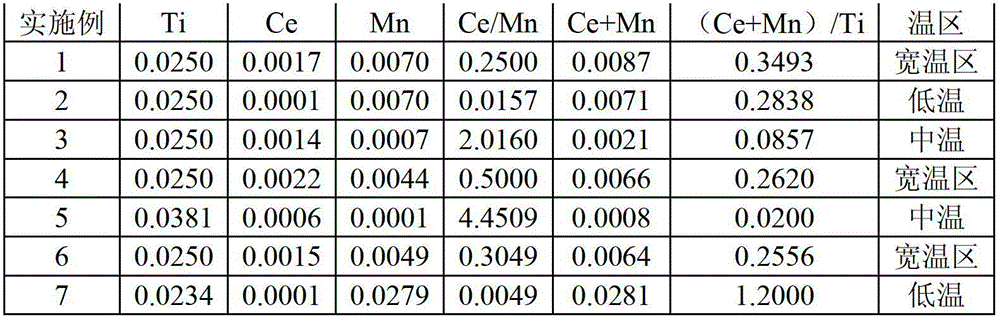

Embodiment 1

[0036] Pretreatment of titanium-based nanotubes: titanium-based nanotubes are hydrotitanic acid nanotubes prepared by strong alkali hydrothermal method, with an inner diameter of 3-5nm, an outer diameter of 7-15nm, and a length of 50-300nm; Soak in excess acetone solution at room temperature for 12 hours, filter with suction and set aside.

[0037] Preparation of wide-temperature core-shell denitration catalyst: Take 2g of pretreated hydrogen titanate nanotubes, add 2.5mL of manganese nitrate solution with a mass fraction of 50%, 0.7583g of cerous nitrate (dissolved in 50mL of water), and Stir and impregnate for 12 hours, then dry at 60°C, heat up to 400°C at a rate of 5°C per minute and bake for 2 hours to obtain a wide temperature core-shell denitration catalyst.

[0038] Catalyst activity and selectivity test: put 0.5g of the prepared catalyst into a fixed bed reactor for activity and selectivity test, the test reaction temperature is 80-450°C, and the space velocity is abo...

Embodiment 2

[0041] Pretreatment of titanium-based nanotubes: titanium-based nanotubes are sodium titanate nanotubes prepared by strong alkali hydrothermal method, with an inner diameter of 3-5nm, an outer diameter of 7-15nm, and a length of 50-300nm; Soak in excess ethanol solution at room temperature for 12 hours, filter with suction and set aside.

[0042] Preparation of low-temperature core-shell denitration catalyst: Take 2g of pretreated sodium titanate nanotubes, add 2.5mL of manganese nitrate solution with a mass fraction of 50%, 0.06g of cerium ammonium nitrate (dissolved in 50mL of water), and stir at room temperature Immerse for 4 hours, then dry at 60°C, heat up to 400°C at a rate of 10°C per minute and bake for 4 hours to obtain a low-temperature core-shell denitration catalyst.

[0043] Catalyst activity and selectivity test: put 0.5g of the prepared catalyst into a fixed bed reactor for activity and selectivity test, the test reaction temperature is 80-450°C, and the space v...

Embodiment 3

[0046] Pretreatment of titanium-based nanotubes: titanium-based nanotubes are sodium titanate nanotubes prepared by strong alkali hydrothermal method, with an inner diameter of 3-5nm, an outer diameter of 7-15nm, and a length of 50-300nm; Put it in excess xylene solution and soak it at room temperature for 6 hours, then filter it with suction and set aside.

[0047] Preparation of medium-temperature core-shell denitration catalyst: Take 2g of pretreated sodium titanate nanotubes, add 0.12g of manganese sulfate (dissolved in 25mL of water), 0.51g of cerium sulfate (dissolved in 25mL of water), stir and impregnate at room temperature 16 hours, then dried at 80°C, and then heated to 450°C at a rate of 15°C per minute and calcined for 5 hours to obtain a medium-temperature core-shell denitration catalyst.

[0048] Catalyst activity and selectivity test: put 0.5g of the prepared catalyst into a fixed bed reactor for activity and selectivity test, the test reaction temperature is 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com