Comprehensive energy-saving method for boiler or industrial furnace and kiln

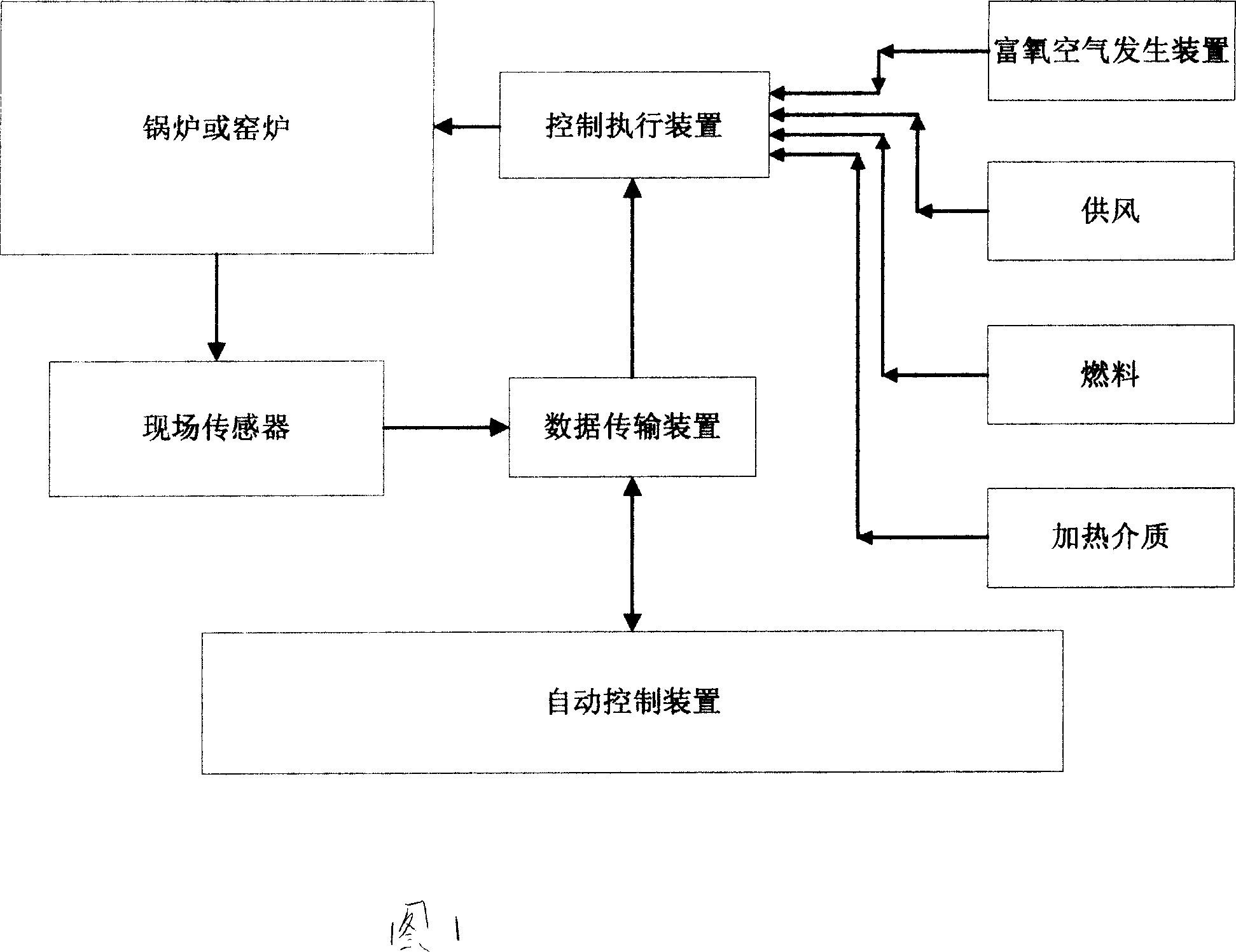

An industrial and kiln technology, applied in the field of comprehensive energy saving, can solve the problems of oxygen-enriched air combustion that cannot achieve energy saving effect, large blast and induced air volume, and inability to accurately adjust the air volume coordination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] The present invention is implemented in the boiler, and the control system is designed and installed according to the present invention. When the combustion-supporting oxygen-enriched air is added to the boiler furnace, the intelligent control system starts to adjust the combustion-supporting air volume and the original blower and induced draft fan, and detects the furnace temperature, heated medium (such as steam) temperature, flow, pressure, and exhaust gas temperature and other parameters. When the heat load increases and the amount of fuel increases, the intelligent control system will automatically increase the pressure of the combustion-supporting air, increase the linear velocity of the combustion-supporting air to make it greater than the smoke overnight, and use a frequency converter to properly adjust the induced air volume, and at the same time use the exhaust gas temperature The parameter is used as the second reference quantity for the adjustment of the ind...

Embodiment 2

[0011] The present invention is implemented in the chemical raw material sodium silicate molten pool furnace, and an automatic control system is designed and installed according to the present invention. When the combustion-supporting oxygen-enriched air is added to the hearth of the molten pool furnace, the intelligent control system detects the field parameters, and then starts to adjust the combustion-supporting air volume and the original blower, and detects parameters such as the furnace temperature, the temperature of the heated medium, and the exhaust gas temperature. When the heat load increases, the amount of fuel increases, and the intelligent control system automatically increases the combustion-supporting oxygen-enriched air pressure by 1.6KPa according to the amount of fuel increase. The parameter is used as the second reference quantity for adjusting the blast volume, so that the melting pool furnace can work in the optimal energy-saving area. Conversely, when th...

Embodiment 3

[0013] Implement the present invention in the cement rotary kiln, design and install the control system according to the present invention. In this system, according to the established adjustment model of the combustion conditions of the rotary kiln, under the adjustment of the automatic control system, the combustion-supporting oxygen-enriched air is added to the pulverized coal burner of the cement rotary kiln to reduce the original air volume of pulverized coal injection, so that The powdered coal sprayed out by the burner accelerates the combustion speed and burnout degree, improves the combustion intensity of the flame, and also reduces the formation of nitrogen oxides and reduces the NOx component in the exhaust gas of the rotary kiln. In the application of the new dry-process cement rotary kiln, the burner of the precalciner kiln must also be adjusted, and the secondary and tertiary air volumes are adjusted by the intelligent control system to ensure the special flame co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com