Multiparameter automatic control method of industrial furnace burner

A technology for industrial furnaces and burners, applied in the control of combustion, lighting and heating equipment, etc., can solve the problems of difficult to achieve the requirements of straight pipe sections, requirements of compact structure, large opening of the air door, etc., to achieve the best combustion effect, avoid Structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

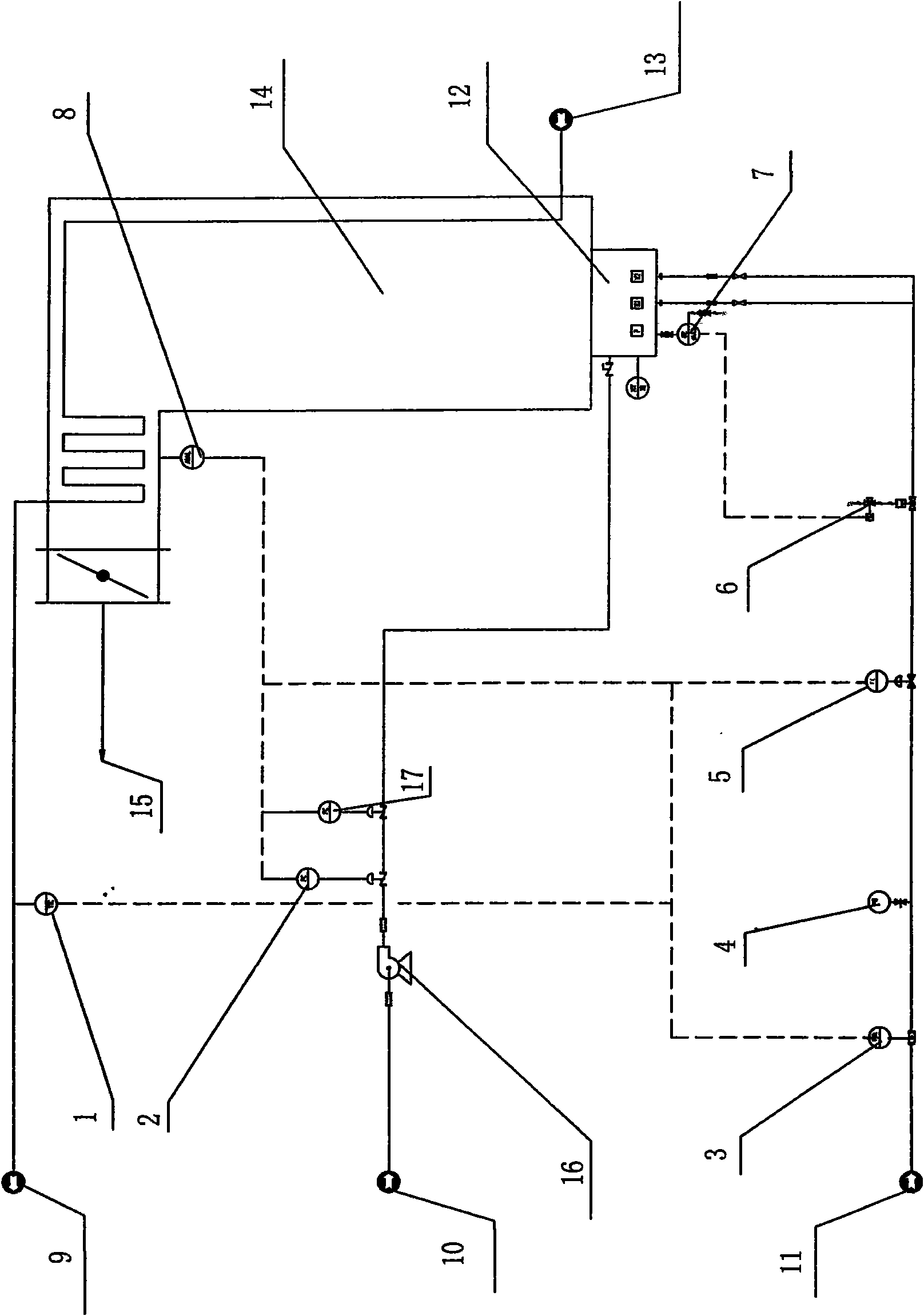

Embodiment 1

[0017] see figure 1 , figure 1 It is a schematic diagram of the multi-parameter automatic control method of the industrial furnace burner of the present invention. Depend on figure 1 It can be seen that the multi-parameter automatic control method of the industrial furnace burner of the present invention is that the fuel flow display control instrument 3, the fuel pressure control instrument 3, and the fuel pressure are sequentially installed on the fuel feed line 11 of the industrial furnace burner along the fuel feed direction. Table 4, fuel flow regulating valve 5 and flameout protection solenoid valve 6; a flame detector 7 is installed on the industrial furnace burner 12, and the flame detector 7 is connected with the control signal of the flameout protection solenoid valve 6; A furnace tube or furnace outlet temperature display control instrument 1 is installed on the outlet pipeline 9, and the furnace tube or furnace outlet temperature display control instrument 1 is r...

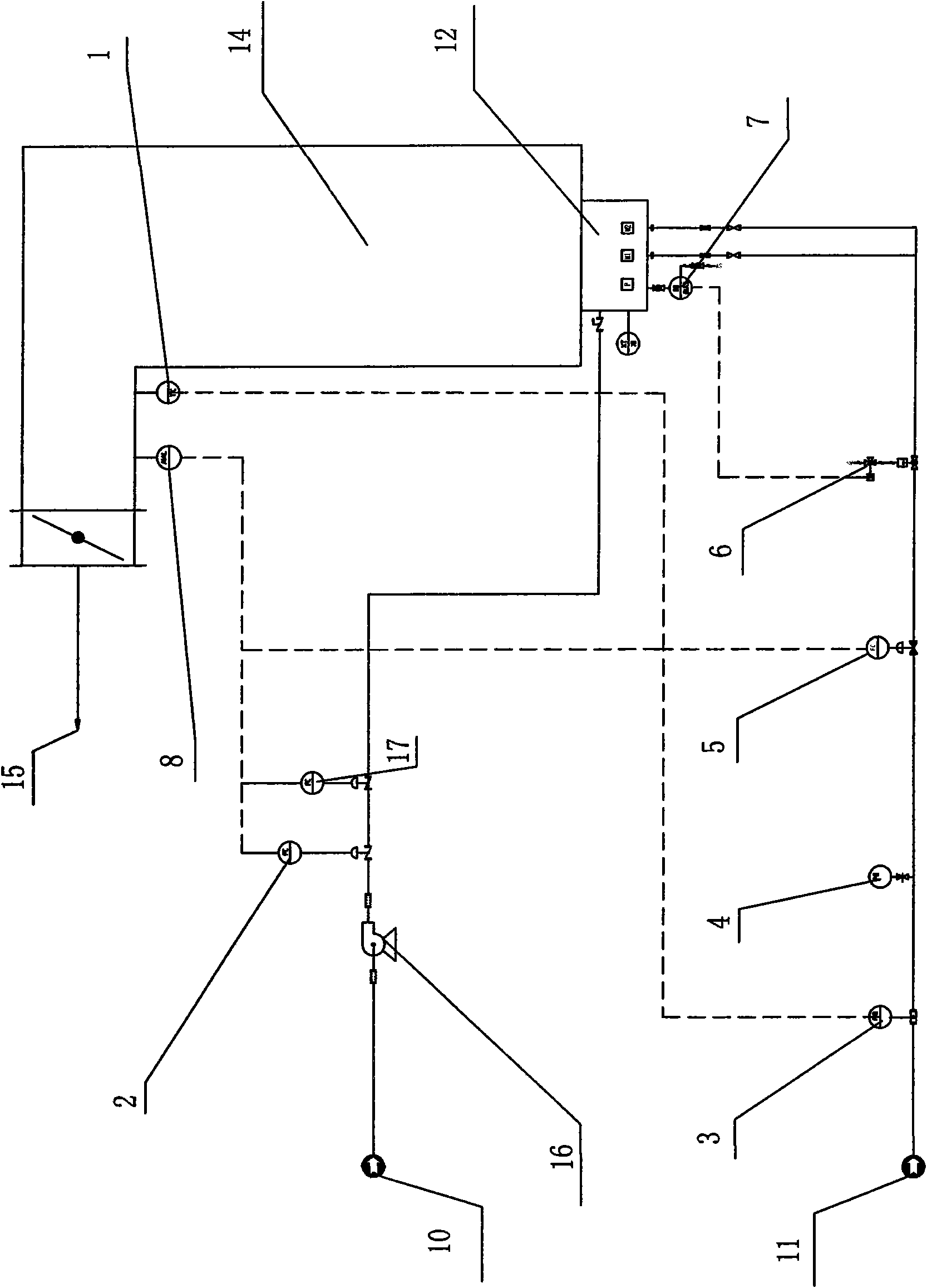

Embodiment 2

[0020] Example 2 as figure 2 As shown, it differs from Embodiment 1 only in that: the furnace tube or furnace outlet temperature display control instrument 1 is installed on the flue gas of the industrial furnace 14 from the furnace or its outlet.

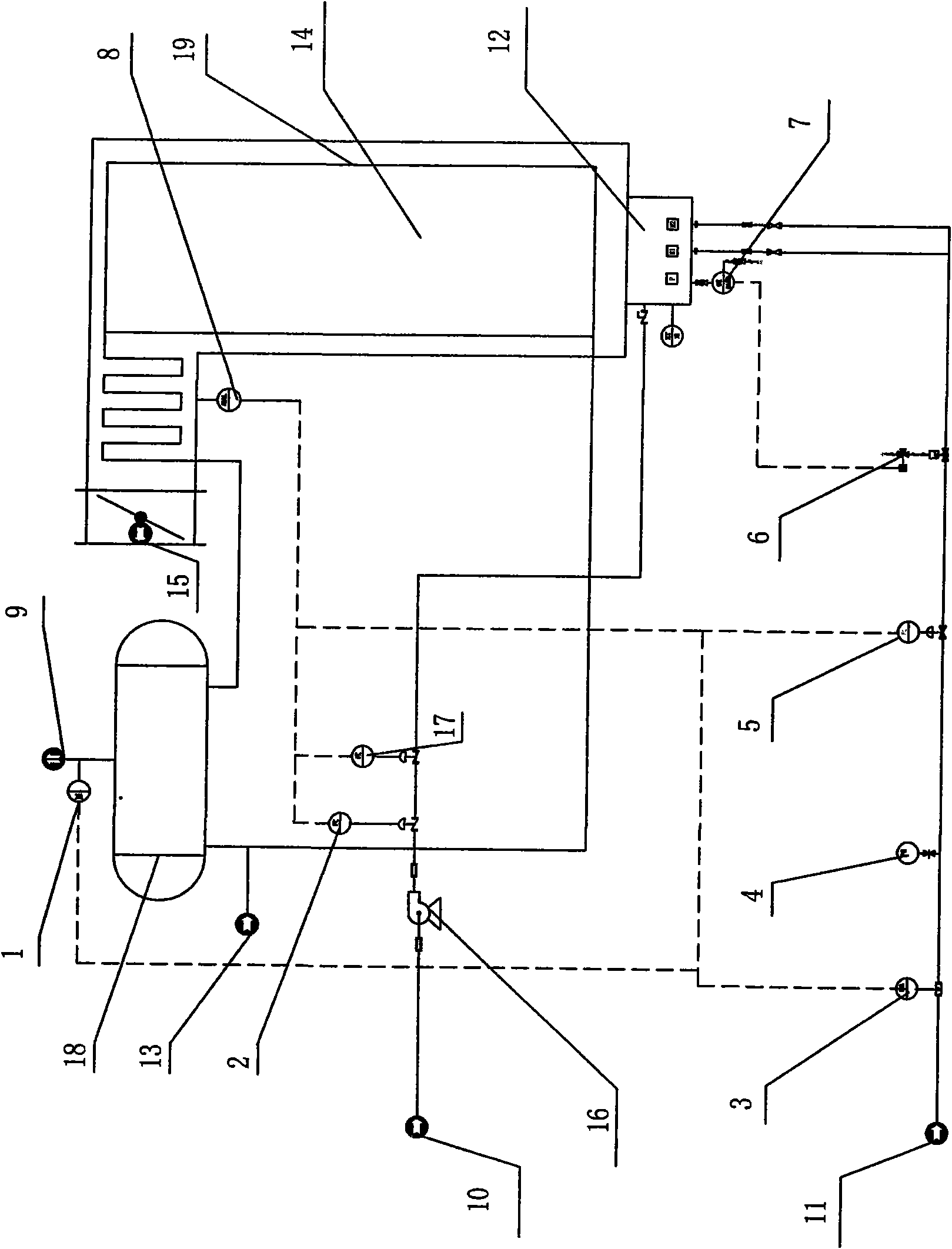

Embodiment 3

[0022] Example 3 as image 3 As shown, it differs from Embodiment 1 only in that: the furnace tube or furnace outlet temperature display control instrument 1 is installed on the steam or hot water outlet pipeline where the boiler tube of the industrial furnace 14 communicates with the steam drum 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com