Infrared radiation coating and use method thereof

A technology of infrared radiation coating and infrared radiation powder, which is applied in the field of infrared radiation energy-saving materials, can solve the problems of insufficient stability of the infrared radiation performance of the coating, and the combination of the coating and the substrate is not strong enough, so as to improve the energy utilization efficiency and achieve excellent high temperature stability. Sex, the effect of promoting bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

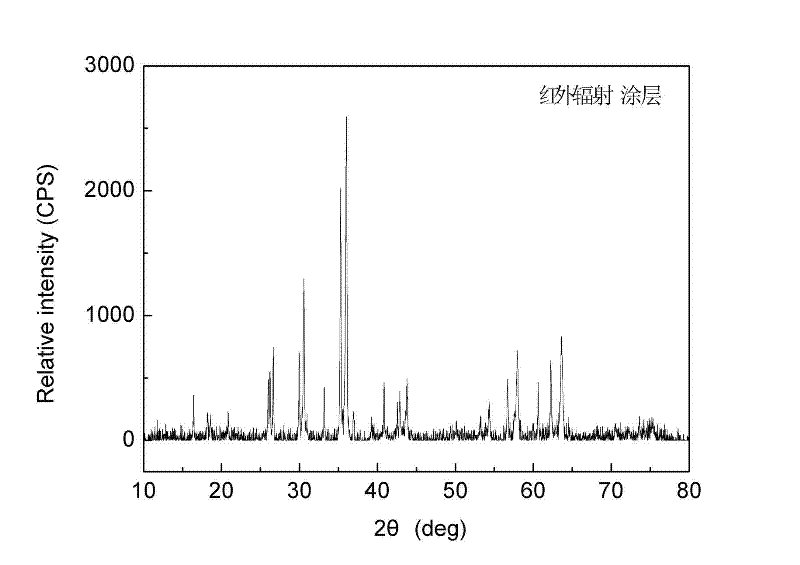

[0047]Embodiment 1: According to the formula of 55% spinel-silicate multi-phase composite system infrared radiation powder, 5% inorganic binding aid, 39.8% binder, 0.2% defoamer by mass ratio, the above-mentioned each The components are weighed according to the proportion, stirred and mixed for 7 hours, and dispersed by a colloid mill to obtain a viscous suspension fluid infrared radiation coating.

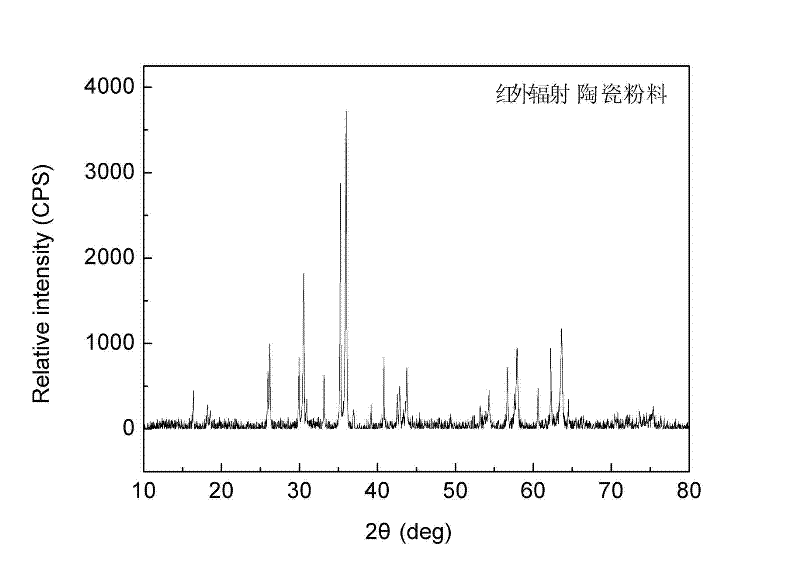

[0048] Among them, the mass ratio of each component in the infrared radiation powder of the spinel-silicate multiphase composite system is: 10% Fe 2 o 3 , 14%MnO 2 , 9%CuO, 2%Mo 2 o 3 , 50%Al 2 o 3 , 12%SiO2 2 , 1.5%MgO, 0.5%TiO 2 and 1% BaO.

[0049] The mass ratio of each component in the inorganic bonding aid is: 20%Al 2 o 3 , 25%SiO2 2 , 8%MgO, 2%TiO 2 , 10%NiO, 7%Cr 2 o 3 , 3%B 2 o 5 And 25% Ti powder.

[0050] The binder is prepared according to the mass ratio of 80% water glass and 20% water.

[0051] When the above-mentioned infrared radiation coating is ...

Embodiment 2

[0053] Example 2: According to the mass ratio, 30% spinel-silicate multiphase composite system infrared radiation powder, 10% inorganic bonding aid, 57.5% binder, 1% anti-settling agent, 0.5% dispersant, For the formula of 0.5% defoamer and 0.5% leveling agent, the above-mentioned components are weighed and compounded according to the proportion, stirred and mixed for 1 hour, and dispersed by a colloid mill to prepare a viscous suspension fluid infrared radiation coating.

[0054] Among them, the mass ratio of each component in the infrared radiation powder of the spinel-silicate multiphase composite system is: 28%MnO 2 , 12%CuO, 6%Mo 2 o 3 , 5%V 2 o 5 、5%WO 3 , 5%Al 2 o 3 , 20%SiO2 2 ,

[0055] 10%MgO, 6%TiO 2 and 3% CaO.

[0056] The mass ratio of each component in the inorganic bonding aid is: 40%Al 2 o 3 , 27%SiO2 2 , 2%MgO, 10%TiO 2 , 5%NiO, 10%Cr 2 o 3 And 6% Zn powder.

[0057] The binder is prepared according to the mass ratio of 80% water glass, 1% et...

Embodiment 3

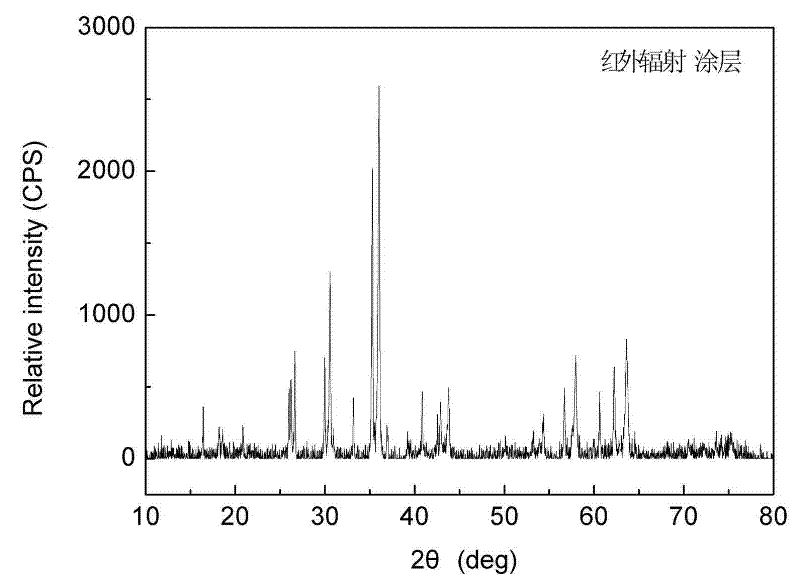

[0059] Embodiment 3: 60% spinel-silicate multi-phase composite system infrared radiation powder, 1% inorganic binding aid, 36% binder, 1% dispersant, 1% defoamer and For the formula of 1% leveling agent, the above-mentioned various components are weighed according to the proportion, stirred and mixed for 3 hours, and dispersed by a colloid mill to obtain a viscous suspension fluid infrared radiation coating.

[0060] Among them, the mass ratio of each component in the infrared radiation powder of the spinel-silicate multiphase composite system is: 9%Fe 2 o 3 , 60%MnO 2 , 4%CuO, 4%Co 2 o 3 , 3%NiO, 2%WO 3 , 8%Al 2 o 3 , 5%SiO2 2 ,

[0061] 3% BaO and 2% CaO.

[0062] The mass ratio of each component in the inorganic bonding aid is: 20%Al 2 o 3 , 20%SiO2 2 , 6%MgO, 2%TiO 2 , 2%NiO, 50%Ti powder.

[0063] The binder is prepared according to the mass ratio of 90% water glass and 10% water.

[0064] When the above-mentioned infrared radiation coating is used on a met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com