Real-time monitoring and safety warning device for temperature of furnace tube of tubular industrial furnace

A technology of real-time monitoring and safety warning, applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as difficulty in achieving the best effect of combustion control, failure to detect in time, hidden safety hazards, etc., and achieve the goal of eliminating the environment and emissivity impact, comprehensive and accurate recording and analysis, and accurate real-time monitoring of the effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

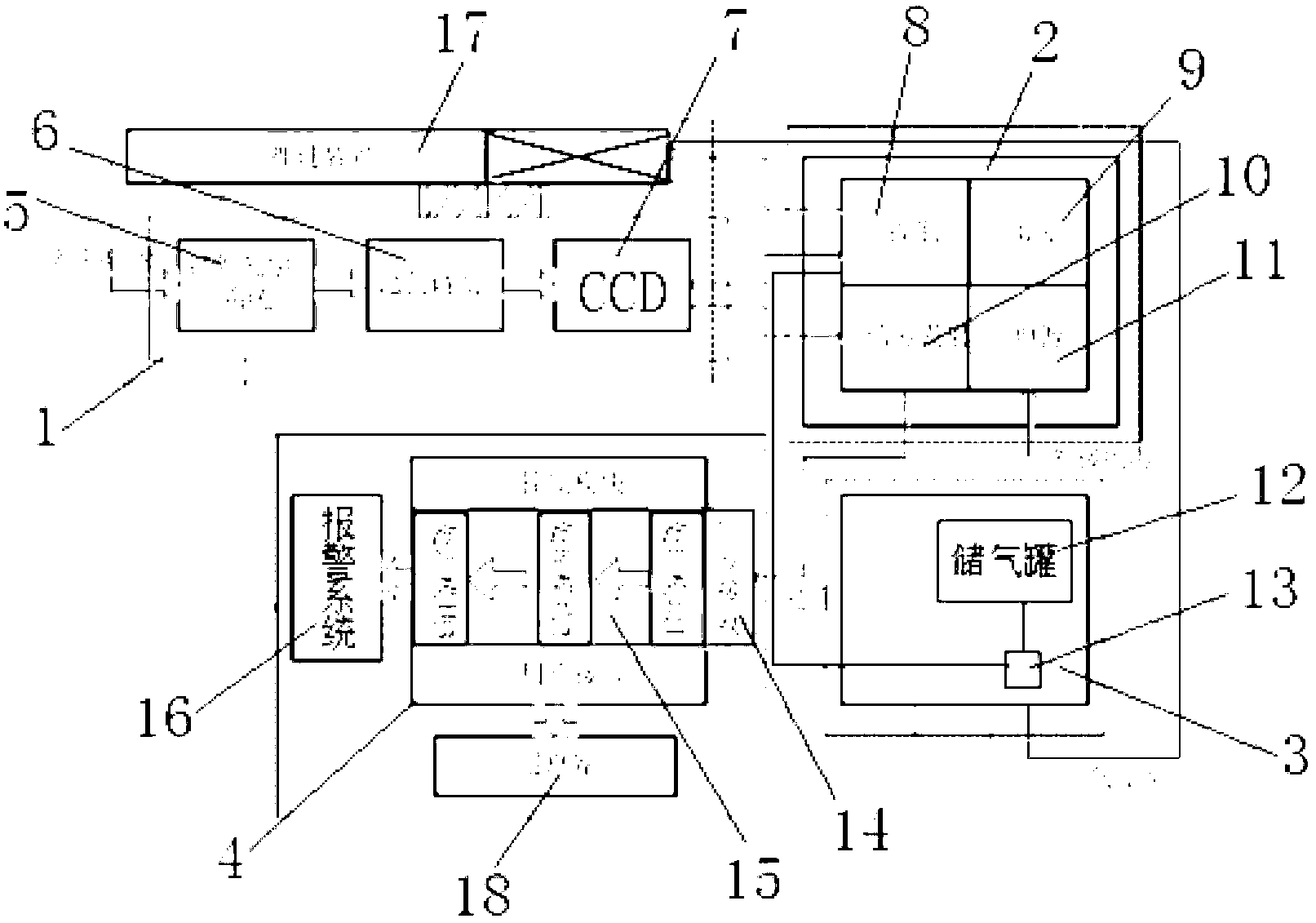

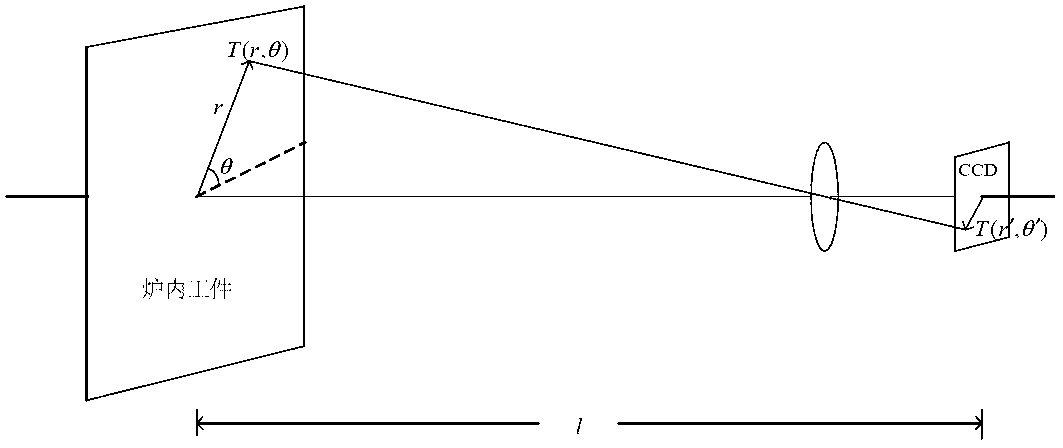

[0026] Such as figure 1 As shown, the tube-type industrial furnace tube temperature real-time monitoring and safety warning device mainly includes four parts: detection equipment 1, electrical control equipment 2, gas source control cabinet 3, and computer processing and control equipment 4. The detection equipment 1 includes High temperature monitoring probe, pneumatic propulsion device 17, high temperature monitoring probe includes infrared optical imaging system 5, colorimetric modulation 6, CCD imaging system 7, the outer side of high temperature monitoring probe is provided with cooling protection device and placed on the pneumatic propulsion device 17, high temperature The monitoring probe has a built-in temperature sensor. The electrical control equipment includes a digital controller 8, a status display module 9, a signal transmitter 10 and a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com