Large-sized industrial kiln lining anchoring piece and method of use thereof

A large-scale industry, anchoring technology, applied in furnaces, fluidized bed furnaces, integral linings, etc., can solve the problems of system-wide operation deviation, system oscillation out of control, etc., and achieve the effects of enhancing traction, enhancing toughness, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

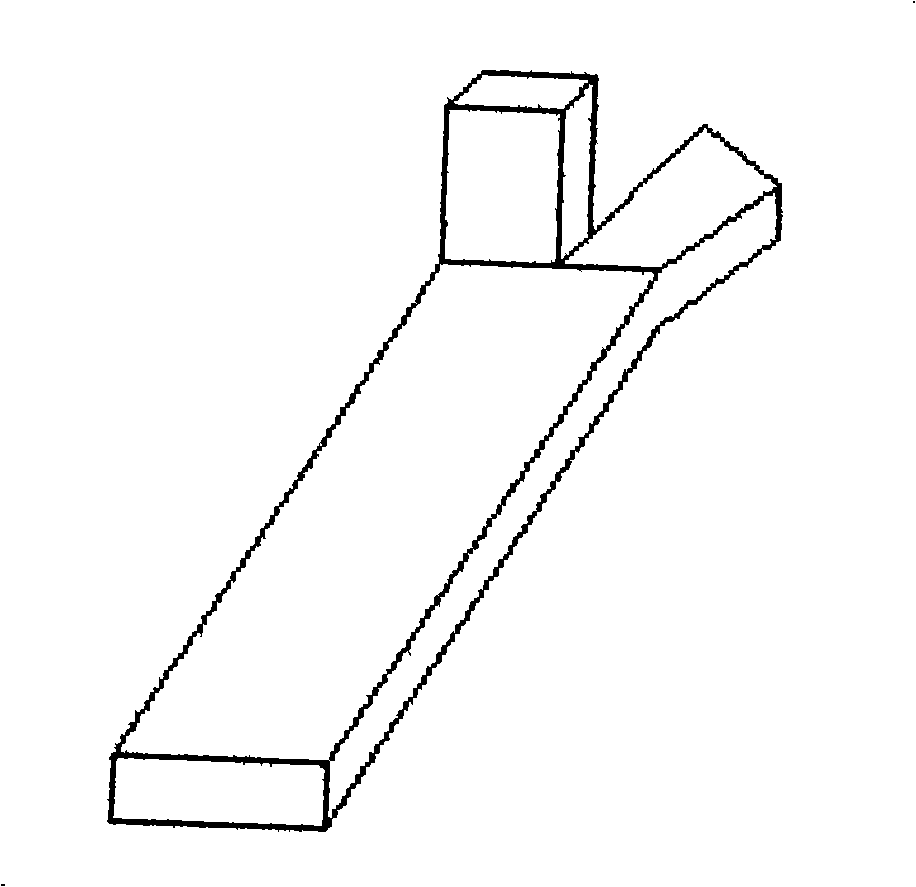

[0037] Furnace side wall anchor configuration

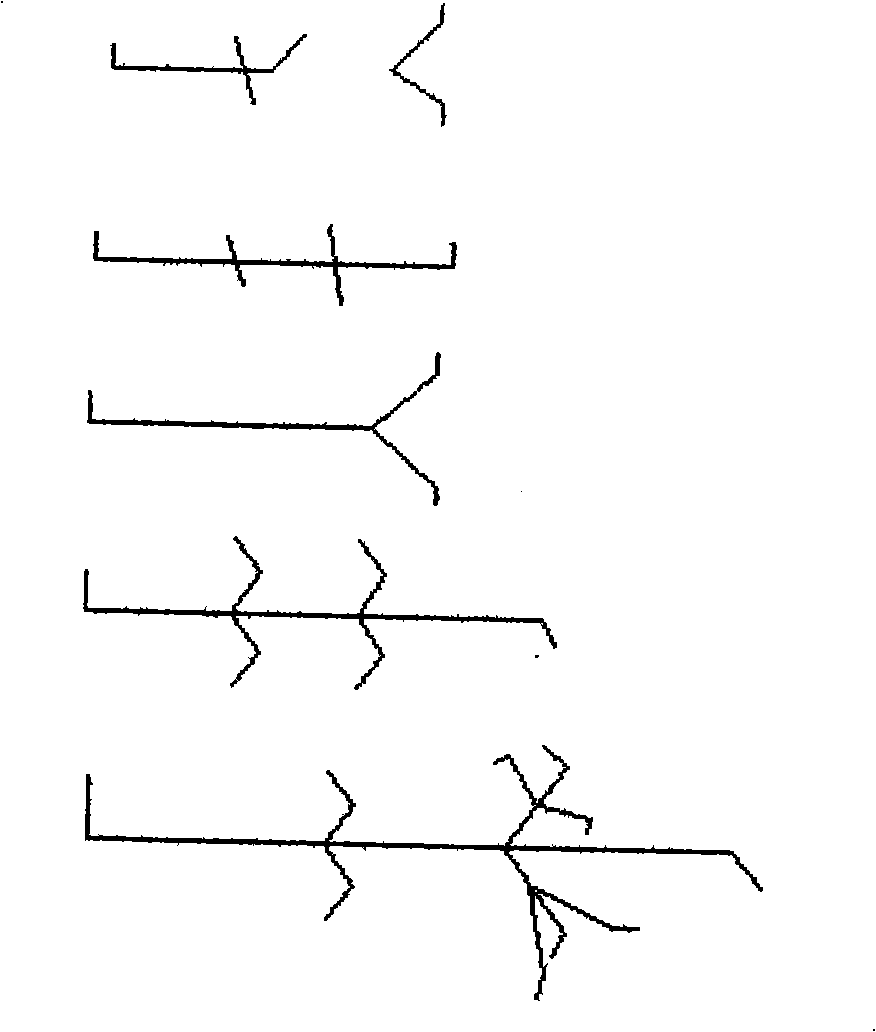

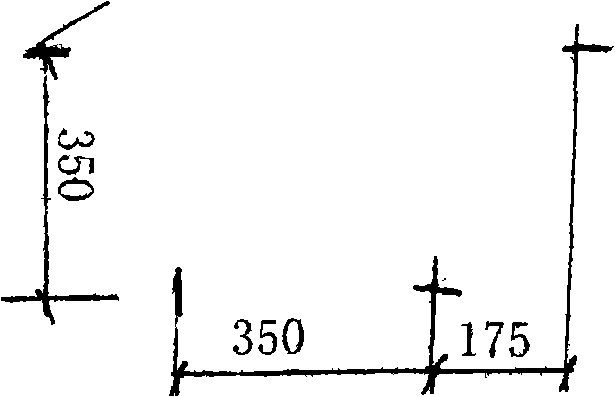

[0038] The uniformly welded rigid thrust anchor bricks on the outer steel shell of the side wall of the furnace body are changed to heat-resistant alloy anchors, and the fixed anchor force of the side wall is changed to a pulling force to adapt to the changing direction of the thermal expansion force of the furnace wall. The "V" shape at the front end of the metal anchor is "Y" shape as a whole, and the angle between the anchor walls of the front beam is > 60°C. The metal anchor is used as the skeleton to separate the amorphous refractory castable layer and the heavy refractory castable The inner layer composed of two layers is combined with the steel outer shell to form a composite side wall structure. The principle of the anchor points of the side fireplace wall is to adopt the method of uniform spacing, horizontal and vertical intervals, and staggered arrangement, and the same is true for the inclined section of the side wall....

Embodiment 2

[0041] Reinforce anchors at turning, critical and slack parts

[0042] Such as Figure 7 As shown, the top flue gas outlet corners of the GSC furnace PO2, PO3, CO1, the rising section of the PO2, PO3, CO1 flue gas inlet and the flue gas outlet of the top grid, these turning points, critical points, and loose connections between the two units are all Al (OH) 3 or Al 2 o 3 The key point for the reverse operation of the high-temperature air flow of the material. The original structural design and material setting of refractory materials have congenital defects, resulting in serious erosion, leaking and tearing of the joints at these key points. In this embodiment, the figure 2 For example, in this anchoring structure, the hoop of the rising flue at the corner is made of a plate-shaped anchor 16 and connecting rib 15 with a larger heat-resistant stainless steel rod to fix the lower edge of the rising flue at a variable angle, and two thrusts are used to anchor the brick beam...

Embodiment 3

[0044] Anchor Configurations in High Wear Areas

[0045] Such as Figure 5 Figure 6 As shown, in the GSC furnace, whether it is the feeding system, Venturi flash drying Al(OH) 3 System, PO1, PO2 cyclone preheating system and key PO3, PO4 roasting separation system and cooling separation system, in the reverse movement of materials and high temperature air flow, especially Al(OH) 3 Convert to Al 2 o 3 In the high-temperature separation parts such as PO3 and PO4, the unbalanced thrust of the volute inlet is very large, which is the most severely worn area in the system. Find the origin O on the upper part of the cyclone (taking the top of the cylinder as the reference plane), and find the parallel at the origin O. At the three reference points of the flue gas inlet and the parallel and inlet flue gas, the three points are respectively welded with vertical ribs, and the three points are respectively welded with three rows of metal anchors downwards (the vertical interval is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com