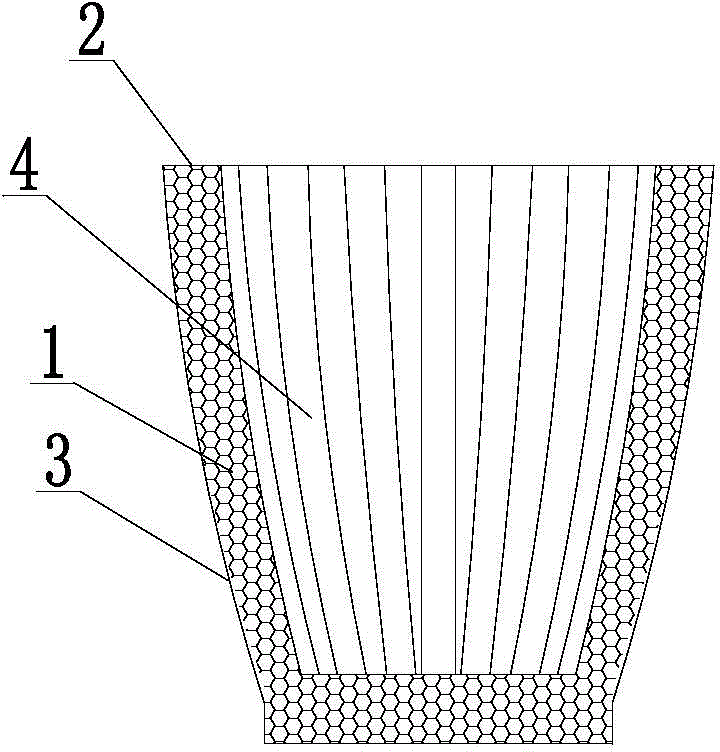

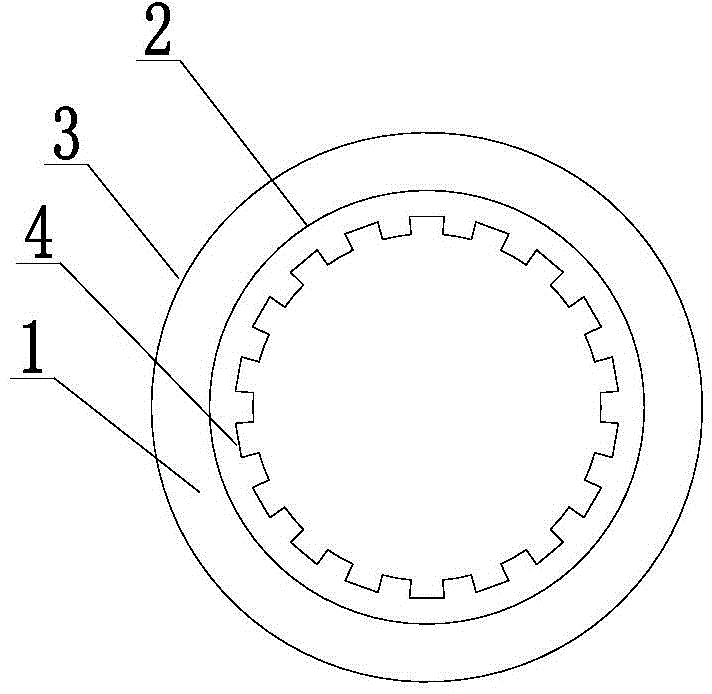

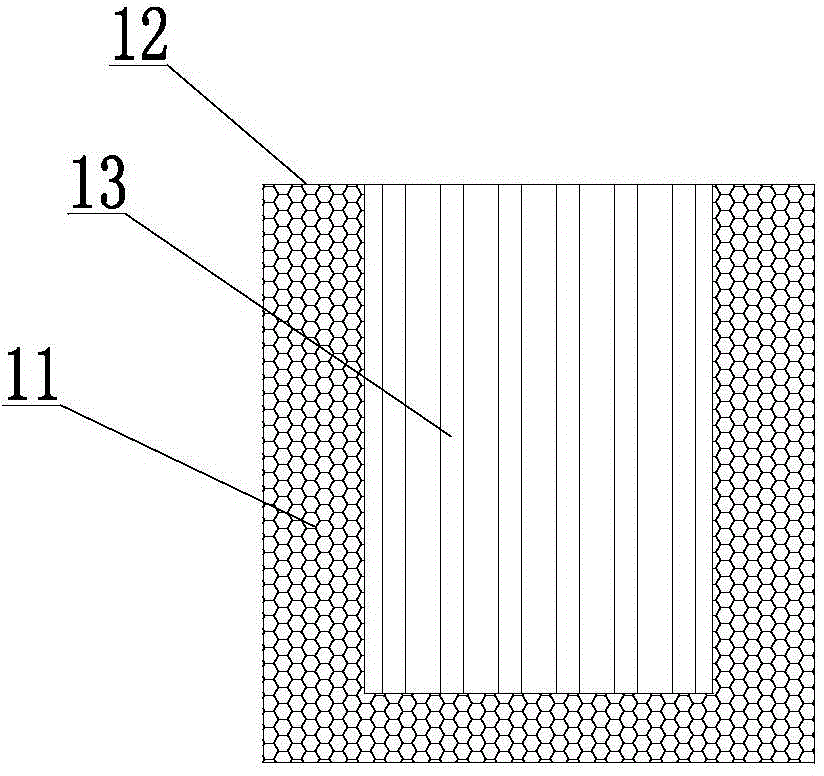

Inner liner material for industrial kiln furnace

An industrial kiln and lining technology, applied in the direction of integral lining, etc., can solve problems such as inability to be applied directly and conveniently, and achieve the effects of good hydrophobic exhaust performance, increased heat storage function, and improved elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The method for preparing the high-emissivity coating is: 15% silica sol, 10% zirconium silicate, 25% chromium oxide, 20% manganese dioxide, 15% iron oxide , 10% magnesium oxide and 5% rare earth are mixed and ground evenly and placed in a box-type high-temperature furnace at 1200 ° C for 2 hours, then poured into cold water to quench the material, and then wet ball milled in a planetary ball mill for 6 hours, adding distilled water Adjust the viscosity of the slurry to be moderate, stir for 3 hours to mix evenly, and age for 24 hours to obtain a high-emissivity coating.

Embodiment 2

[0028]The method for preparing the high-emissivity coating is: the mass percentage is 14% silica sol, 9% zirconium silicate, 24% chromium oxide, 21% manganese dioxide, 16% iron oxide , 11% magnesium oxide and 5% rare earth are mixed and ground evenly and placed in a box-type high-temperature furnace at 1200 ° C for 2 hours, then poured into cold water to quench the material, and then wet ball milled in a planetary ball mill for 6 hours, adding distilled water Adjust the viscosity of the slurry to be moderate, stir for 3 hours to mix evenly, and age for 24 hours to obtain a high-emissivity coating.

Embodiment 3

[0030] The method for preparing the high-emissivity coating is: the mass percentage is 16% silica sol, 11% zirconium silicate, 26% chromium oxide, 19% manganese dioxide, 14% iron oxide , 9% magnesium oxide and 5% rare earth are mixed and ground evenly, and then placed in a box-type high-temperature furnace at 1300 ° C for 2 hours, then poured into cold water to quench the material, and then wet ball milled in a planetary ball mill for 6 hours, adding distilled water Adjust the viscosity of the slurry to be moderate, stir for 3 hours to mix evenly, and age for 24 hours to obtain a high-emissivity coating.

[0031] Many high-efficiency and energy-saving prefabricated parts are installed on the furnace roof and furnace wall of the industrial furnace; the expansion of the furnace wall is greatly improved, and the heat transfer area is more than doubled; in addition, the inner wall of the cavity is coated with a high emissivity layer, so that The emissivity is between 0.92 and 0.96...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com