Heat resisting vacuum heat insulating material

A vacuum insulation and heat-resistant technology, applied in heat exchange equipment, lighting and heating equipment, and pipeline protection through heat insulation, etc., can solve problems such as failure to maintain vacuum state, rupture, and melting of bag-shaped containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

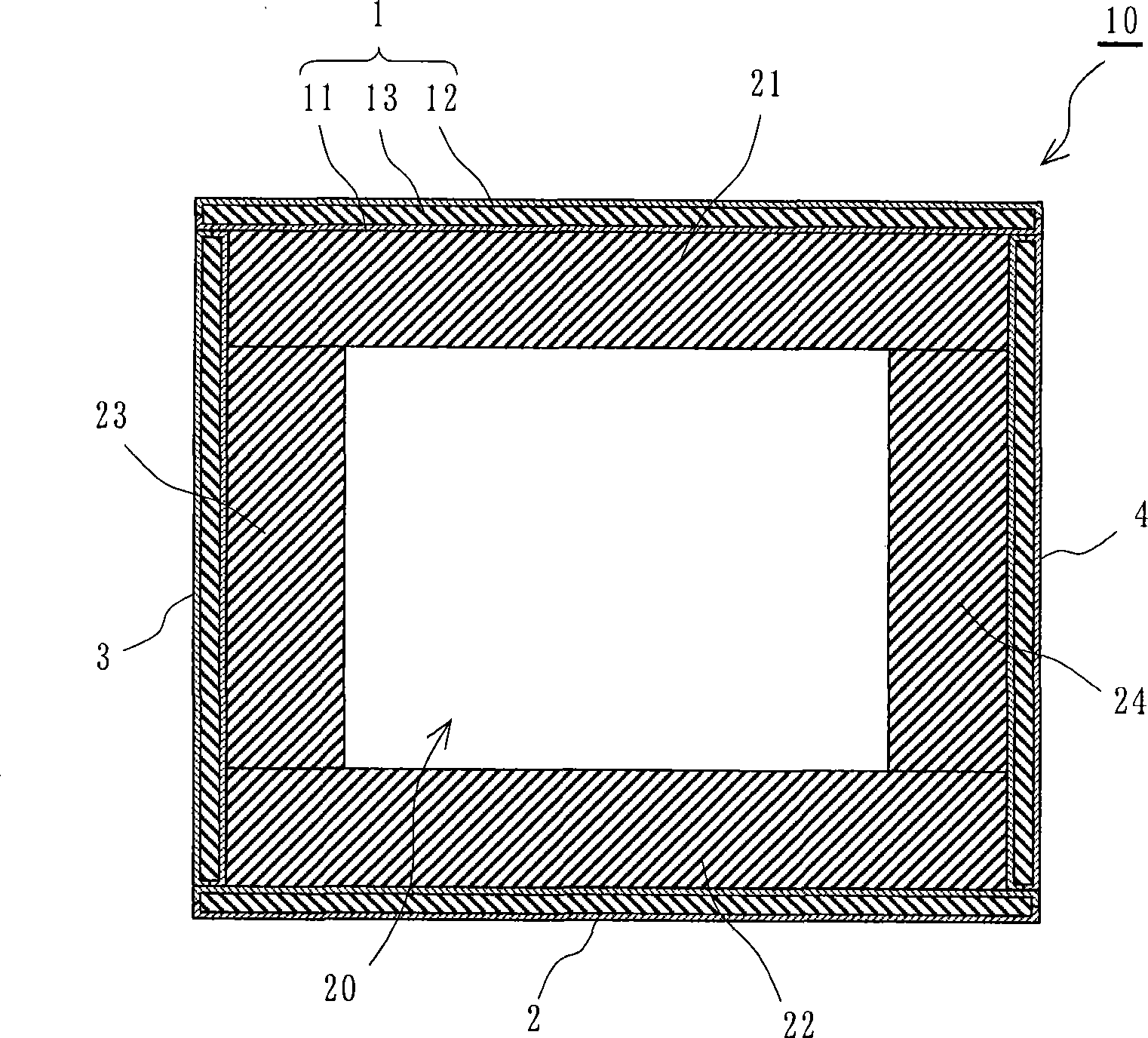

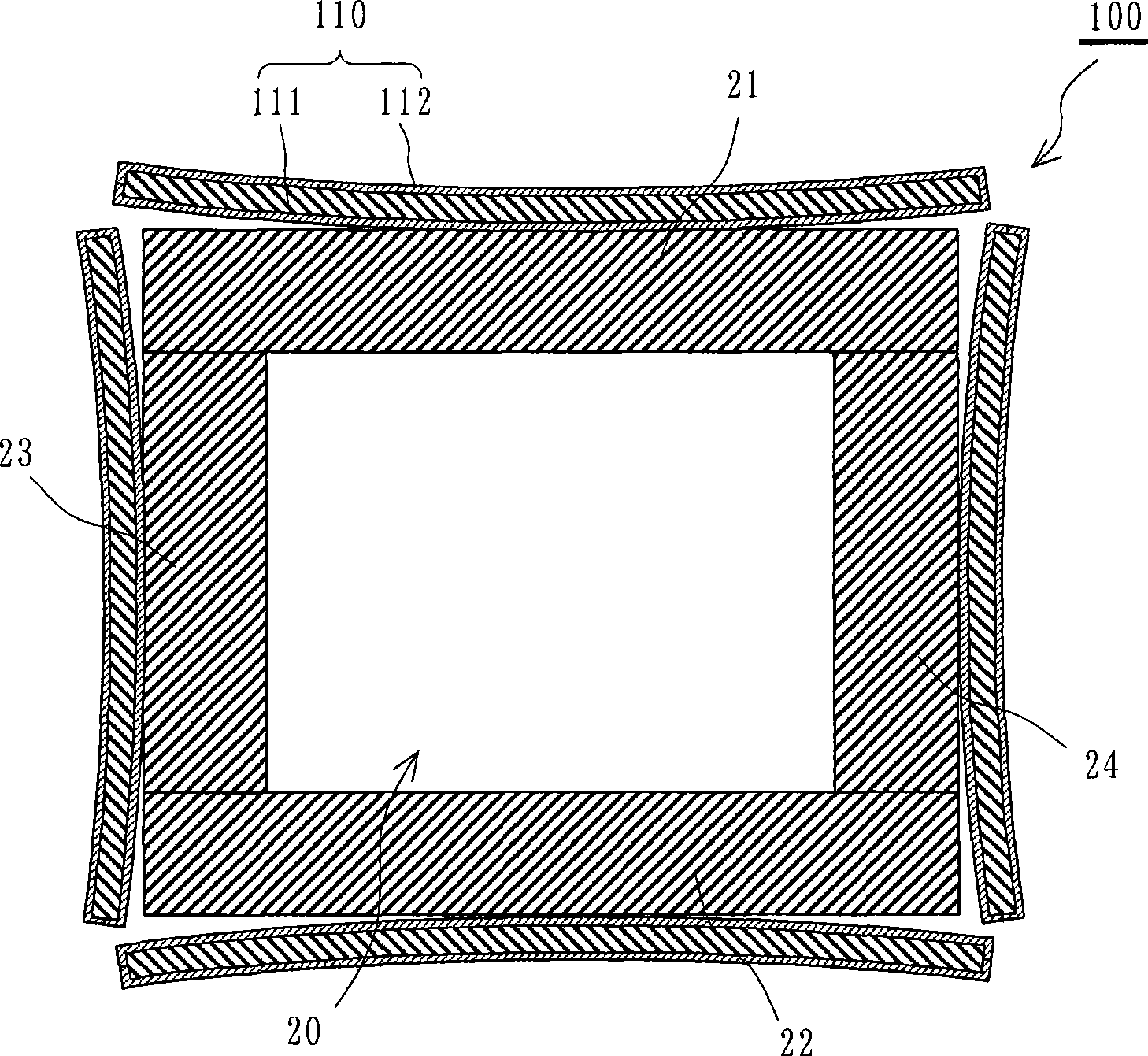

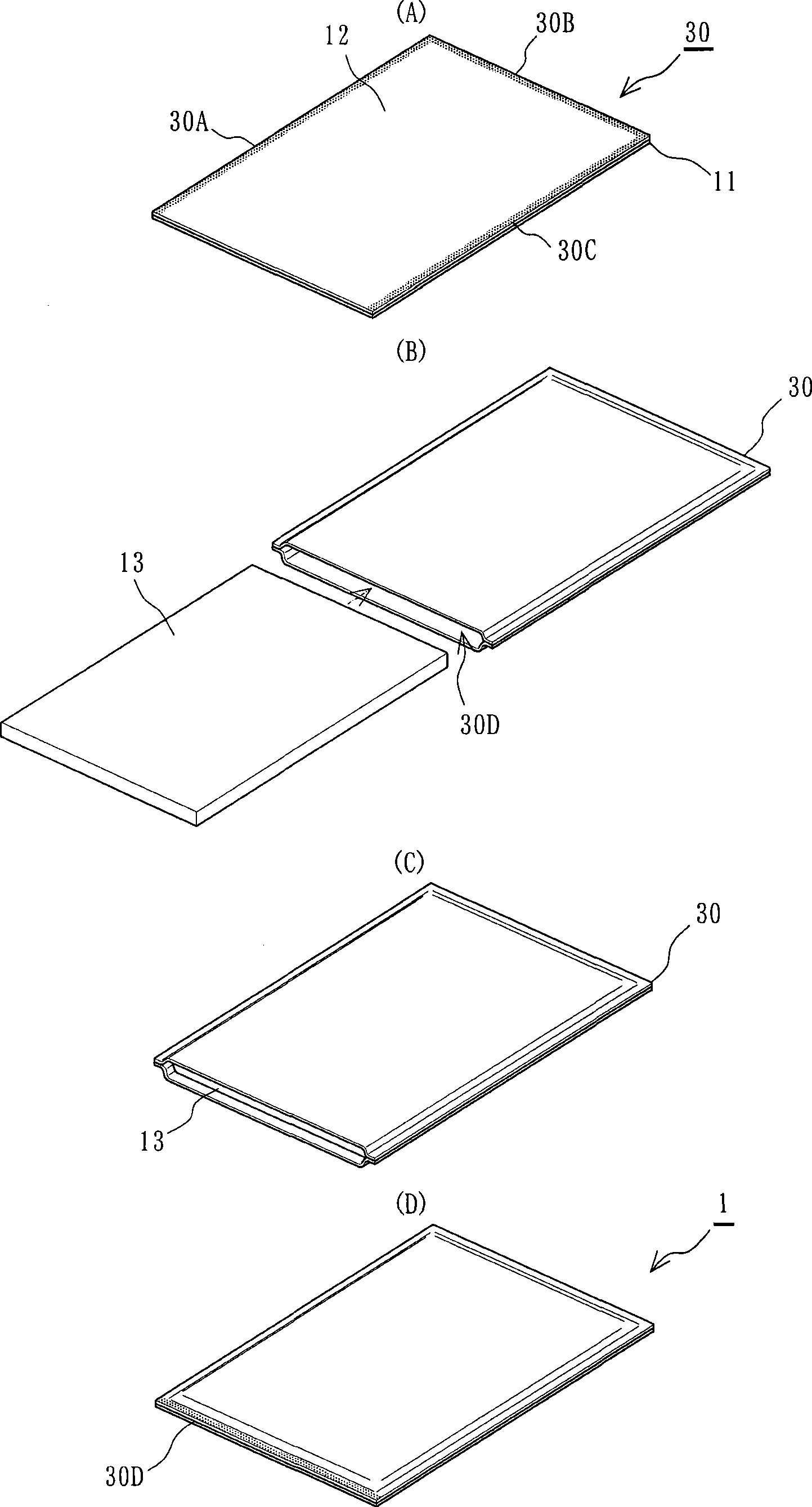

[0027] figure 1 It is a cross-sectional view of a heating device to which the heat-resistant vacuum insulation material according to the embodiment of the present invention is applied. As an example, the heating device 10 performs heat treatment in which a plate-shaped treatment object such as a plurality of glass substrates is kept at a treatment temperature of about 220° C. to 230° C. for a certain period of time. Therefore, the heating device 10 has the heat-resistant heat insulating materials 21-24 and the heat-resistant vacuum heat insulating materials 1-4.

[0028] The heat-resistant heat insulating materials 21 to 24 constitute a wall surface surrounding the heating chamber 20 . The heating chamber 20 accommodates a plurality of processing objects. The heating chamber 20 is heated by a heater not shown so as to maintain the processing temperature. The heat-resistant heat insulating materials 21 to 24 are heat insulating materials excellent in heat resistance, such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com