Bell-type movable full fiber resistance furnace

A full-fiber, resistance furnace technology, applied in electric furnace heating, furnace, furnace type, etc., can solve the problems of low workpiece quality, low production efficiency, and many dark areas of heating, so as to ensure personal safety, improve productivity, and reduce work. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

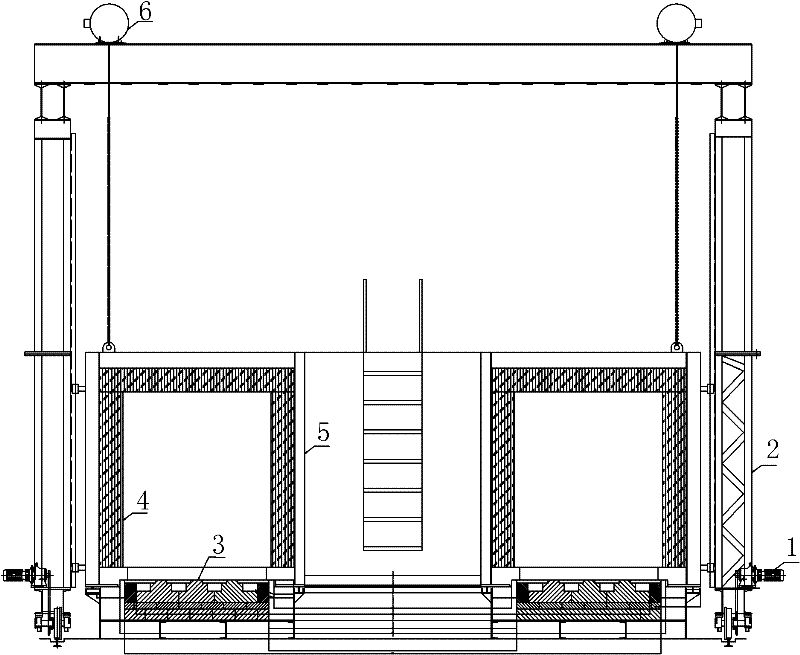

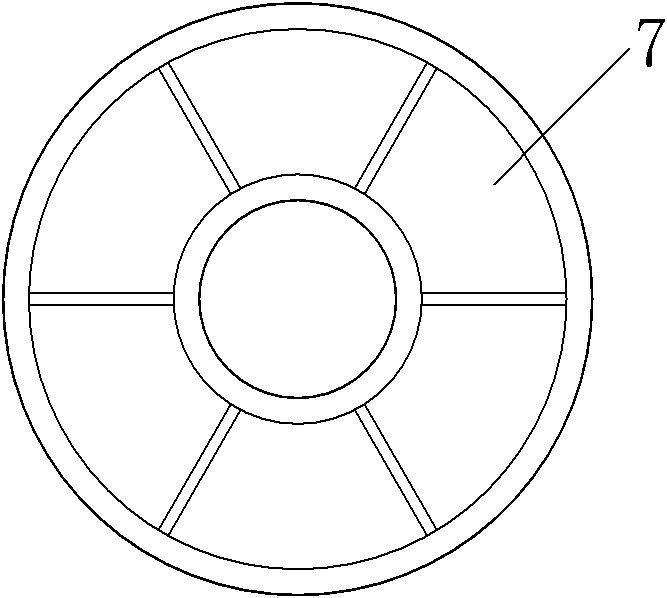

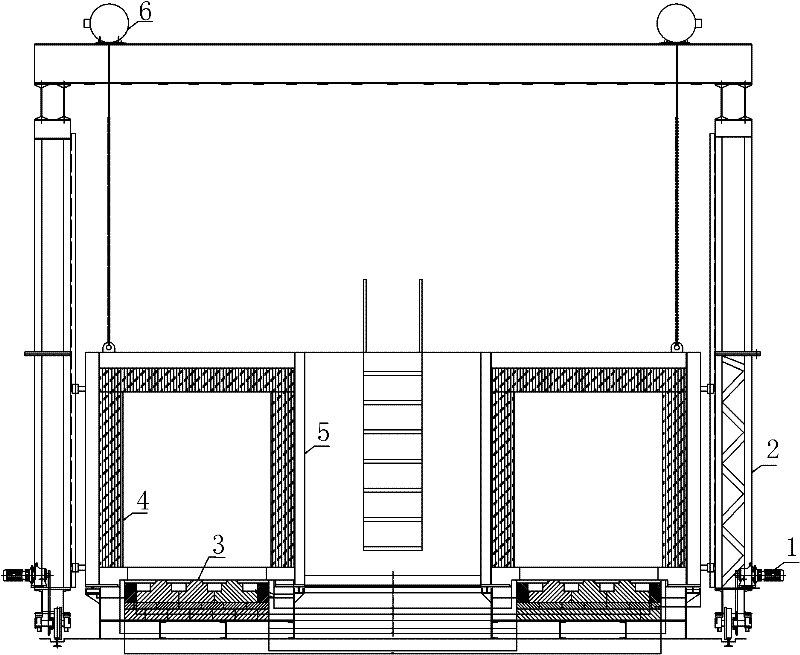

[0012] Such as figure 1 As shown, a kind of movable bell jar type all-fiber resistance furnace of the present invention comprises a furnace cover 5, a lifting mechanism 6 for moving the furnace cover 5, a furnace stand 3 for supporting the furnace cover 5, a furnace frame 2 for installing the lifting mechanism 6, and The transmission mechanism 1 connected to the furnace frame 2, the furnace cover 5 includes an inner furnace cover and an outer furnace cover, the inner furnace cover is a hollow structure, and a heating component 4 is arranged between the inner furnace cover and the outer furnace cover; the furnace base 3 is laid with heating bricks 7. The heating bricks 7 are spliced and combined to form several spaced concentric rings.

[0013] In this embodiment, the heating brick 7 is a curved brick that can be spliced and combined to form a ring, and the differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com