Heated air circulation bake oven

A hot air circulation oven and hot air circulation technology, applied in lighting and heating equipment, furnaces, overall linings, etc., can solve the problems of large local temperature differences and uneven material changes, and achieve uniform heating and good temperature uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

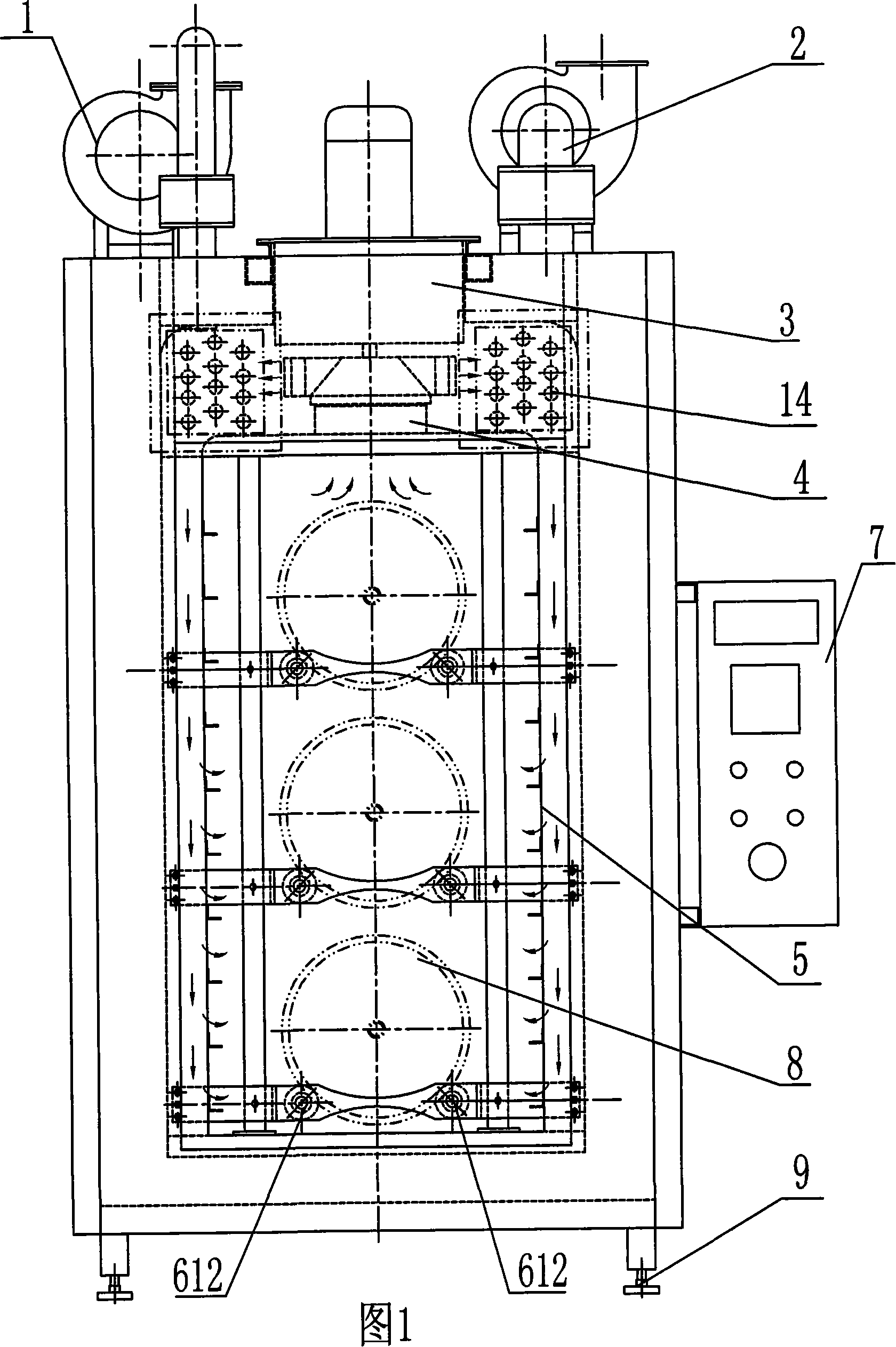

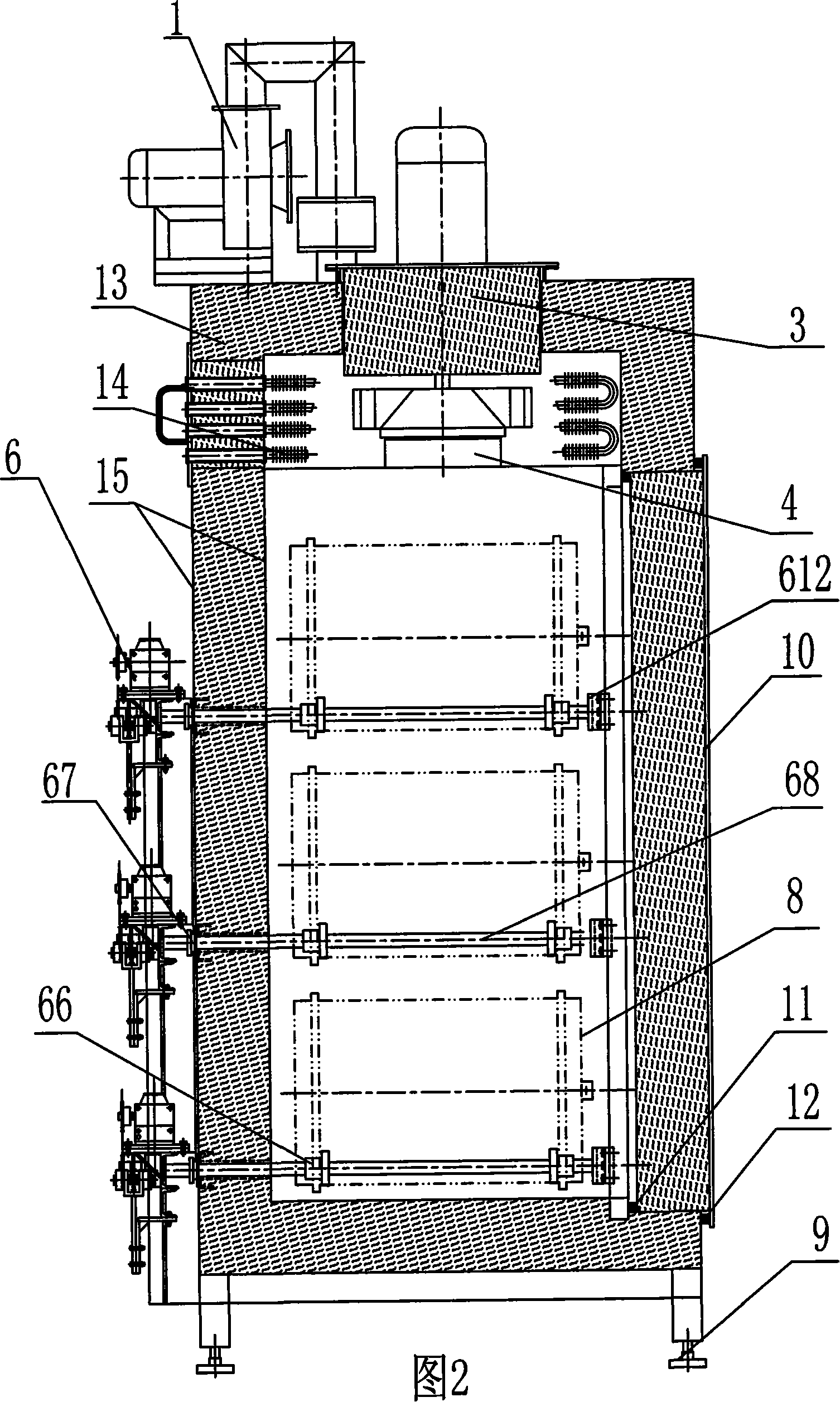

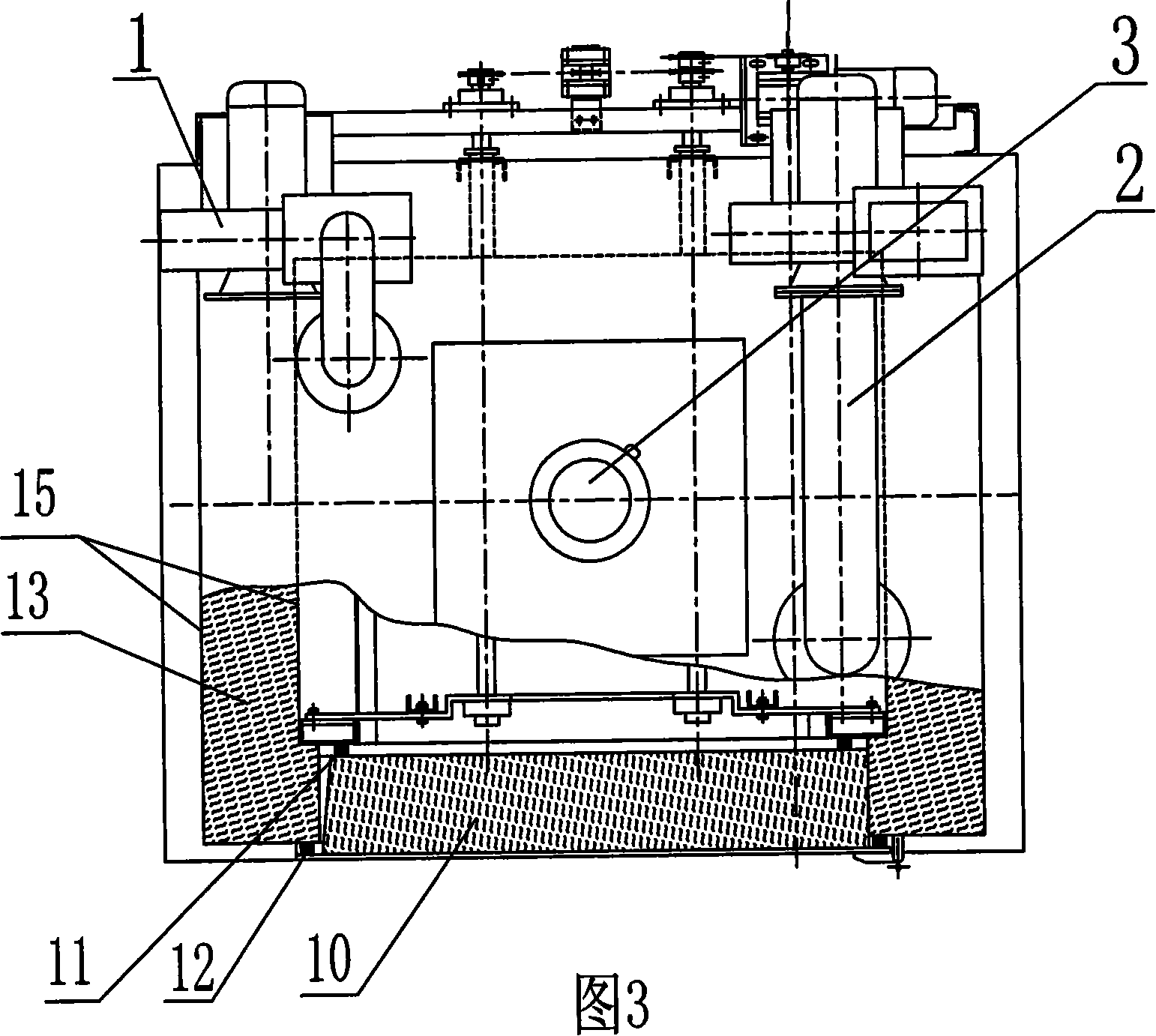

[0049] Referring to Figures 1, 2, and 3, and referring to Figures 4 to 8, the hot air circulation oven of the present invention belongs to an electric furnace with periodic operation. It mainly includes the main body of the electric furnace, which is welded by stainless steel square tubes and steel plates, including the furnace shell 15, the furnace door 10 and the door frame, and the bracket 64 arranged on the back; the furnace shell 15 is divided into inner and outer layers. An insulation layer 13 is arranged between the layers of furnace shells, and the insulation layer 13 is filled with refractory fiber insulation materials. The thickness of the insulation layer is determined according to the rated temperature required for heat treatment and the heat loss of the oven.

[0050] The main body of the electric furnace of the present invention is respectively provided with a hot air circulation system, a bucket rotation system, and a rapid cooling system; wherein,

[0051] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com