Trihydrate alumina gas phase fluidization calcining furnace lining

A fluidized roasting, aluminum hydroxide technology, applied in fluidized bed furnaces, furnaces, integral linings, etc., can solve the problems of material falling off at expansion, unreasonable structure, cracks, etc., to enhance impact resistance and improve use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Adopt Danish Smith 1400T / D AL(OH) 3 Dilute phase fluidized roaster.

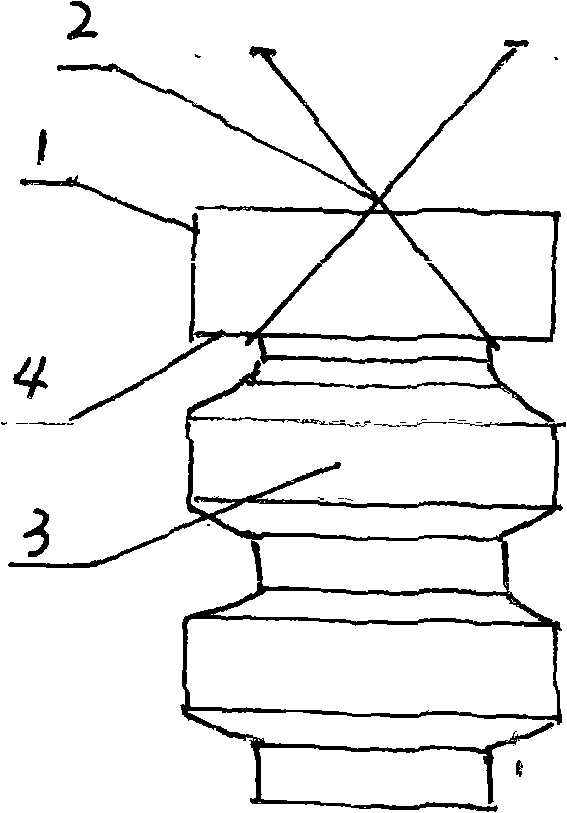

[0038] Its newly-built furnace lining structure is designed as: cyclone cooler CO1, CO2, CO3, main roaster PO4, hot air separation cyclone PO3, cyclone preheater PO2, riser pipe inclined roof and furnace body roof are designed as flexible hanging 1 plus refractory casting materials to keep the furnace top stable, and the flue part of the PO3 top is reinforced with a high-temperature skeleton;

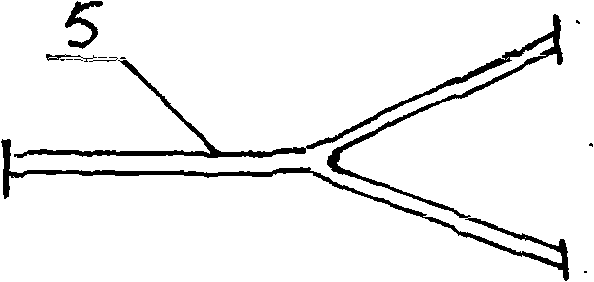

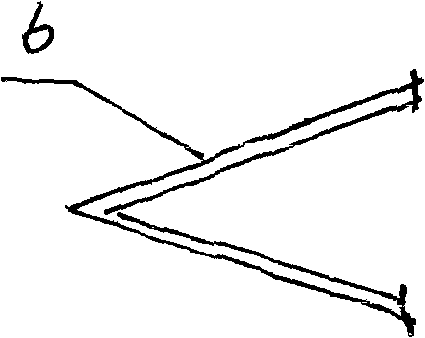

[0039] Change the rigid thrust anchoring brick on the side wall of the furnace body into a point-shaped heat-resistant metal anchor piece 5, and change the fixed anchoring force on the side wall into a pulling force to adapt to the direction of expansion of the furnace wall;

[0040] Reinforce the furnace lining with heat-resistant alloy anchors at the slack parts and critical and turning parts of all structural layers of the GSC furnace;

[0041] The feeding pipes and anchors of all wear-resistant linings of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com