Reduction furnace operation control method

A technology of operation control and reduction furnace, which is applied in the direction of temperature control by electric means, chemical instruments and methods, auxiliary controller with auxiliary heating device, etc., can solve the problem of uneven distribution of heat field and gas field of large reduction furnace, Achieve the effect of increasing the yield of disposable materials, improving product quality and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

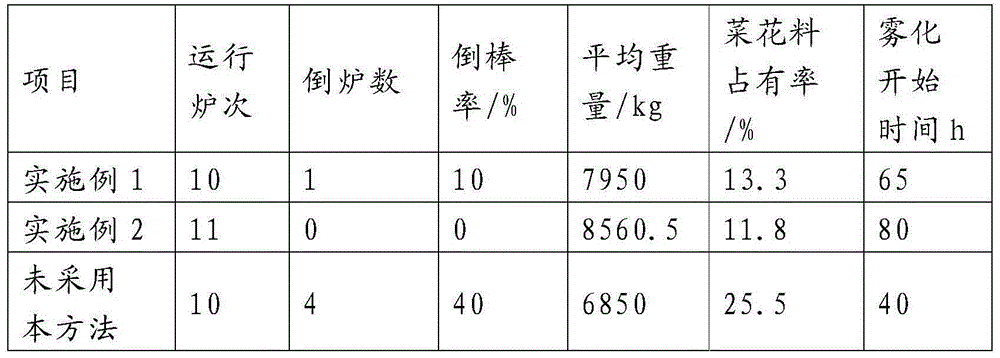

Embodiment 1

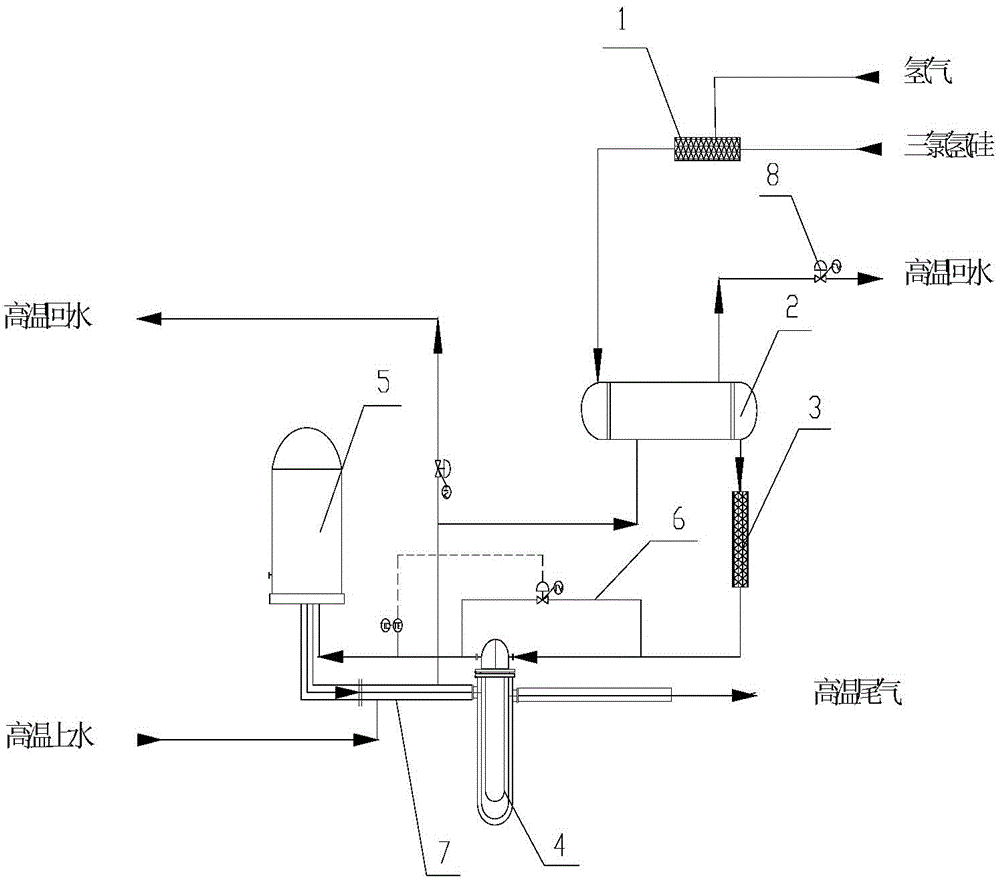

[0069] Embodiment 1 is the case where the tail gas hole is located in the middle of the bottom plate of the reduction furnace. 48 pairs of silicon rods are divided into 4 layers and arranged on the chassis of the reduction furnace, and the silicon rods of each layer are distributed concentrically with the exhaust holes.

[0070] The initial pressure in the reduction furnace 5 is set to 0.55MPa, and the initial temperature is set to 1120-1150°C. The initial flow rate of hydrogen is 15-25kg / h, during feeding process, open trichlorosilane regulating valve gradually, make trichlorosilane and hydrogen carry out heat energy exchange in feed preheater 2 with hydrogen, obtain The mixed gas of trichlorosilane and hydrogen is transported to the reduction furnace 5 through the tail gas heat exchanger 4, so as to feed the reduction furnace 5.

[0071] When the mixed gas is initially delivered to the reduction furnace 5, the molar ratio of the mixed gas of hydrogen and trichlorosilane is ...

Embodiment 2

[0081] Example 2 is the case where the tail gas holes are evenly distributed on the outside of the bottom plate of the reduction furnace (at the circumference of the bottom plate). 48 pairs of silicon rods are set on the reduction furnace chassis, and 3-6 pairs of silicon rods in the middle of the reduction furnace chassis are used as the core circle (that is, the first layer of silicon rods), and the rest of the silicon rods are divided into 3 layers (2-4 layers Silicon rods), each layer of silicon rods is concentrically distributed with the core circle.

[0082] The operation control process of the reduction furnace in embodiment 2 is the same as that of embodiment 1, and will not be repeated here. The difference between embodiment 2 and embodiment 1 is that the control process of applying different current intensities to the silicon rods of each layer by using phase-splitting current is different. In embodiment 2, the control process of applying different current intensitie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com