Uninterrupted circulating valve

A technology of circulating valve and valve core, which is used in wellbore/well components, earth-moving drilling, flushing wellbore, etc., can solve problems such as wellbore instability, drilling tool failure, wellbore collapse, etc., to avoid wellbore pressure The effect of fluctuation, reducing lost circulation, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

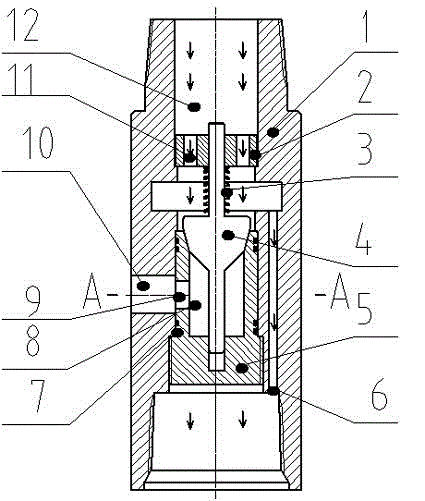

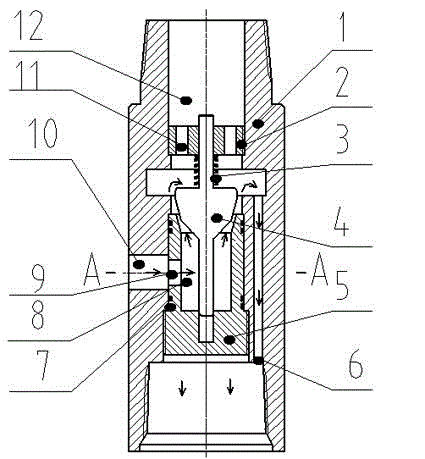

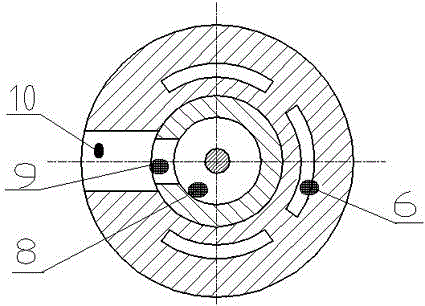

[0014] Attached below figure 1 , attached figure 2 , attached image 3 And attached Figure 4 The present invention is further described:

[0015] An uninterrupted circulation valve includes a housing, a main channel and a bypass channel. The shell 1 is cylindrical, with a male thread on the upper end and a female thread on the lower end, a through hole A12 and a channel A6 in the axial direction, and a channel B10 in the radial direction; the spring seat 2 is respectively installed inside the through hole A12 from top to bottom , spring 3, valve core 4 and valve seat 5; spring seat 2 is disc-shaped, with a through hole B13 processed in the axial center, and an axial through hole C11 is processed outside the through hole B13; spring 3 is installed on the spring seat 2 and valve Between the cores 4, spring thrust is applied to the valve core 4; the upper part of the valve core 4 is a cylindrical valve core guide rod, the valve core guide rod is inserted into the through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com