System for gripping a processing tool, storage system and method

A technology of clamping equipment and storage system, applied in the field of storage system, can solve the problems of high manufacturing cost and high space requirement, and achieve the effect of reducing non-production time and rapid tool switching cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Next, embodiments of the present invention will be described in detail. Further modifications of specific individual features presented here can each be combined with one another to form new embodiments.

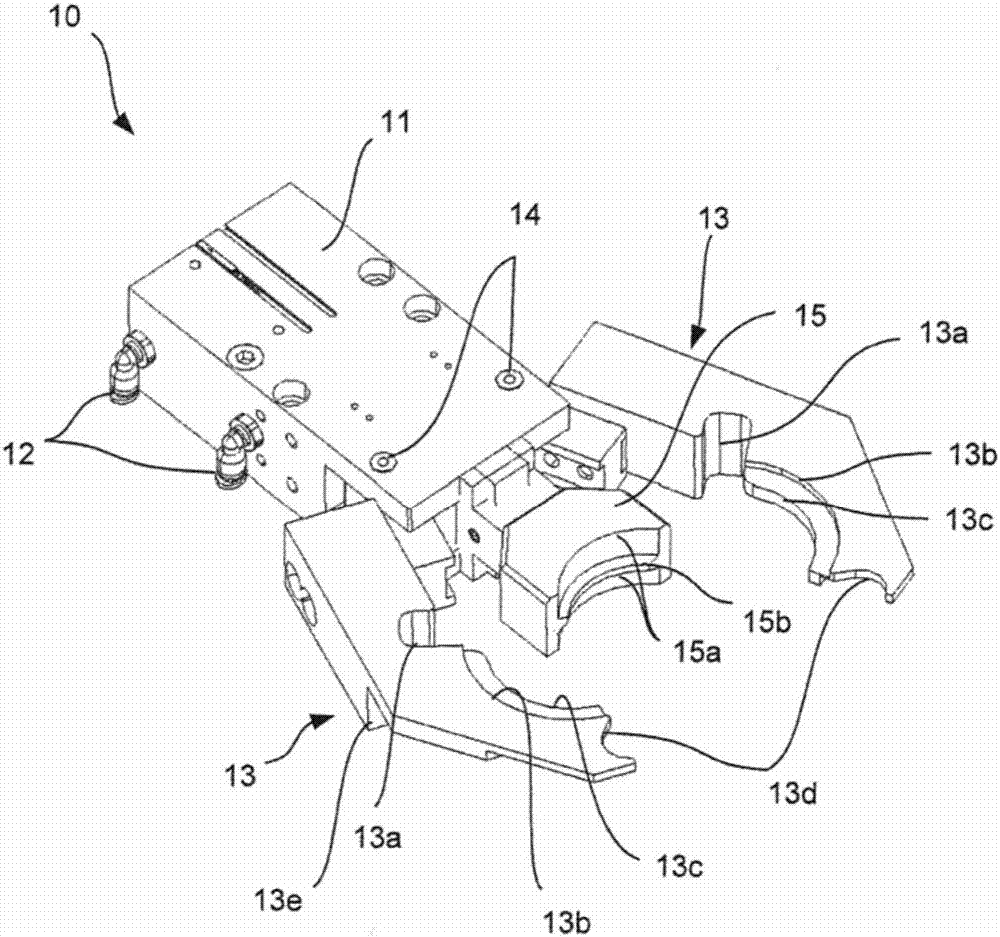

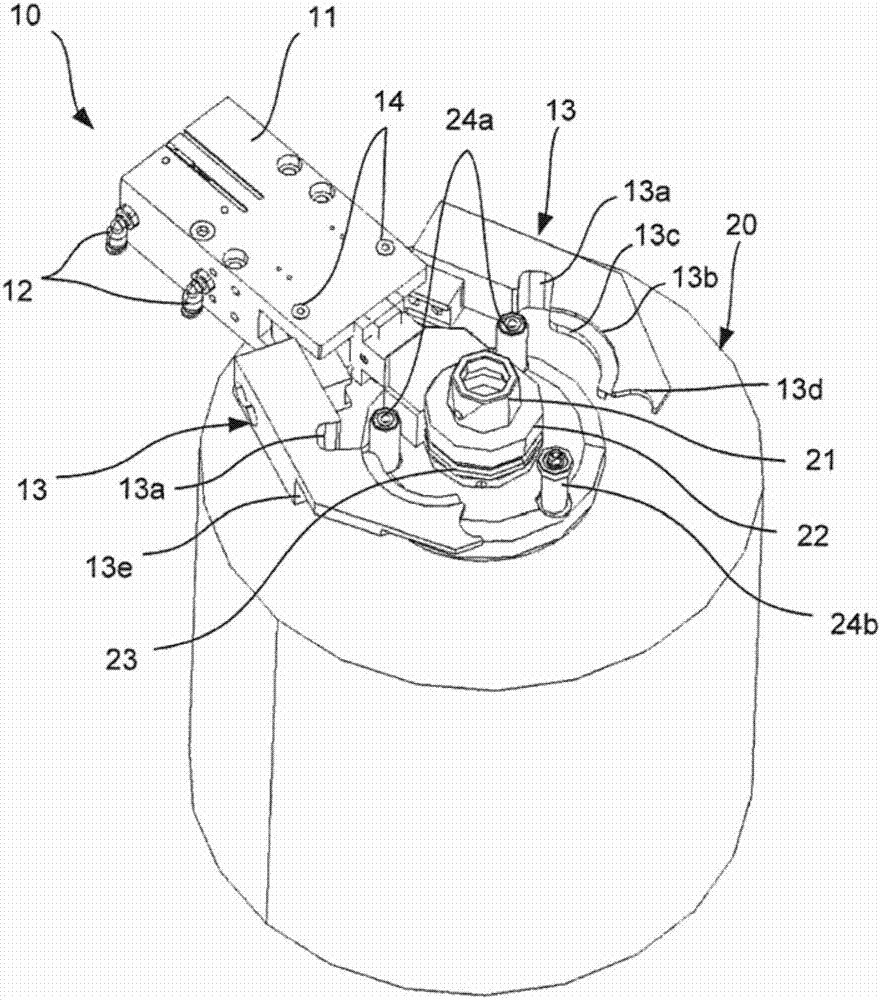

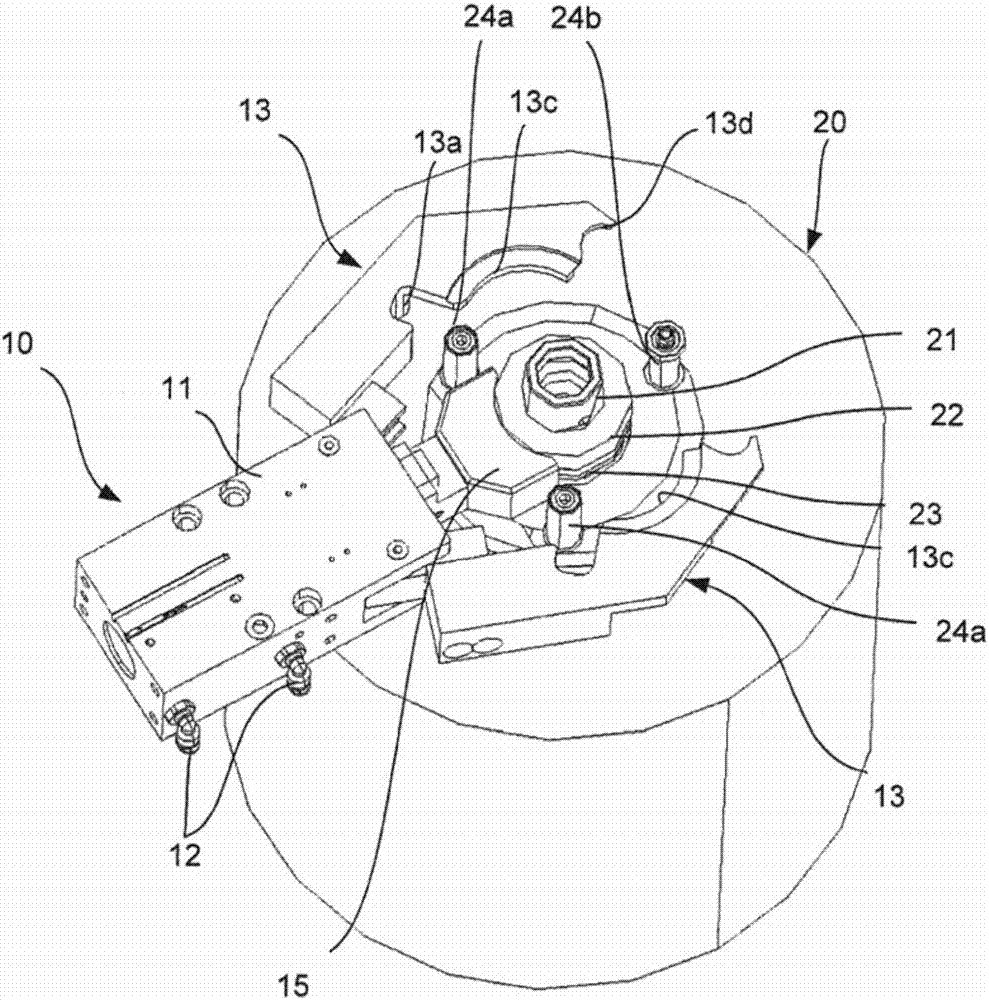

[0037] figure 1 One embodiment of a clamping device 10 according to the invention is shown. The holding device 10 comprises a base body 11 which is provided with a compressed air connection 12 . A medium for actuating the clamping jaws 13 is supplied via the compressed air connection 12 , whereby the clamping jaws 13 of the clamping device 10 can be opened and closed pneumatically.

[0038] In this embodiment, the base body 11 comprises a compressed air connection 12 which operates a pneumatic mechanism for pivoting the clamping jaws 13 . In an alternative embodiment, the clamping tongs 13 can also be hydraulically actuated. In another variant, it is also possible to provide an electric motor on the base body 11 for actuating the clamping pliers 13 .

[0039]The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com