A polyhedron rotary welding tool shared by multiple car bodies

A polyhedron and spin welding technology, applied in auxiliary devices, vehicle parts, manufacturing tools, etc., can solve the problems of increased equipment cost, complex structure, large space occupation, etc., and achieve the effect of short switching cycle, simple operation and small space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

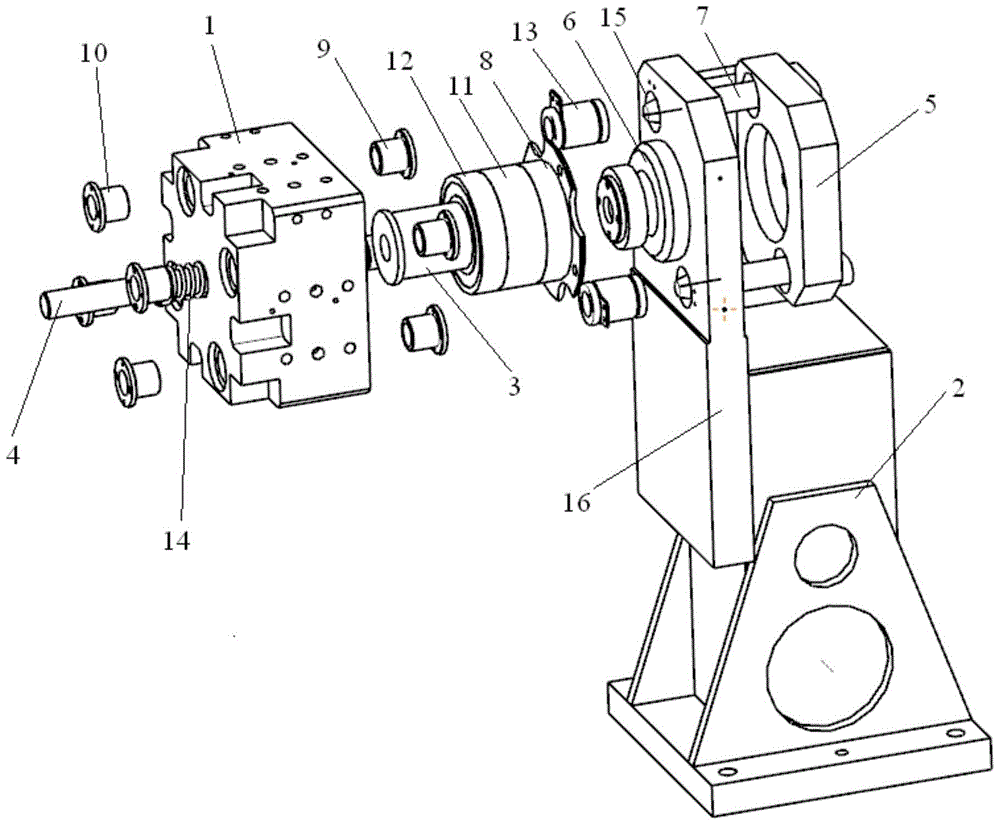

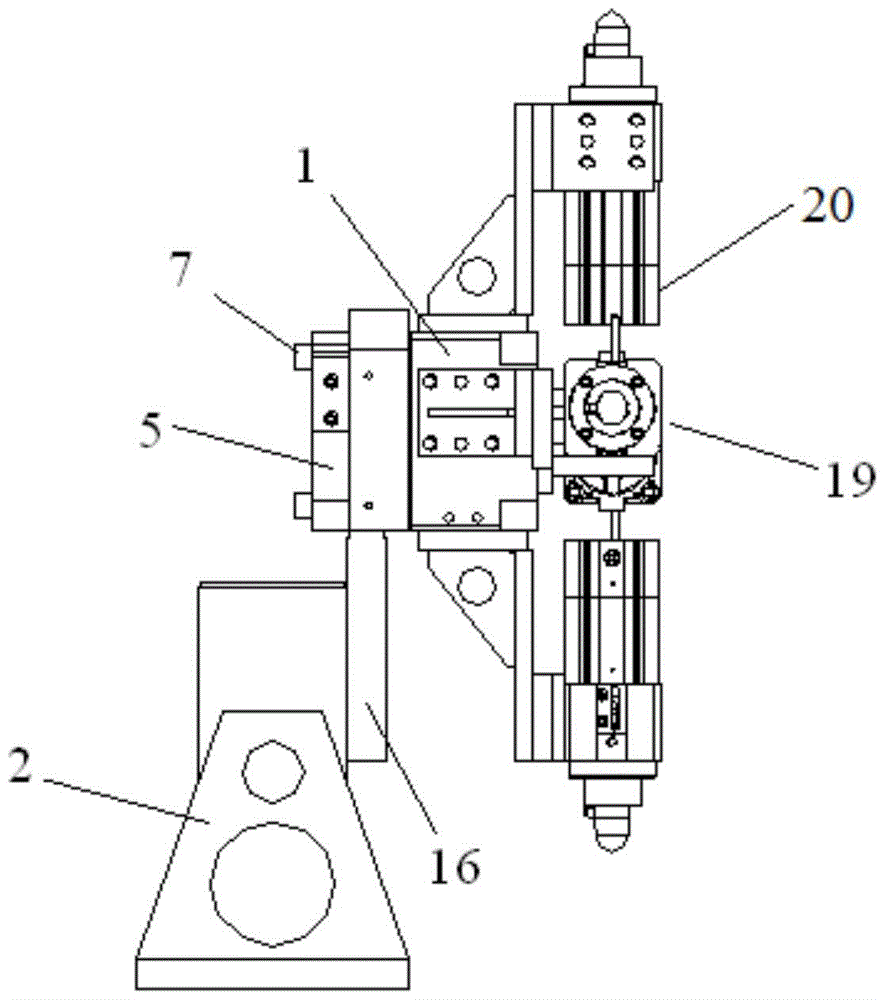

[0029] A polyhedron rotary welding tool shared by multiple car bodies, its structure see figure 1 with figure 2 ,include:

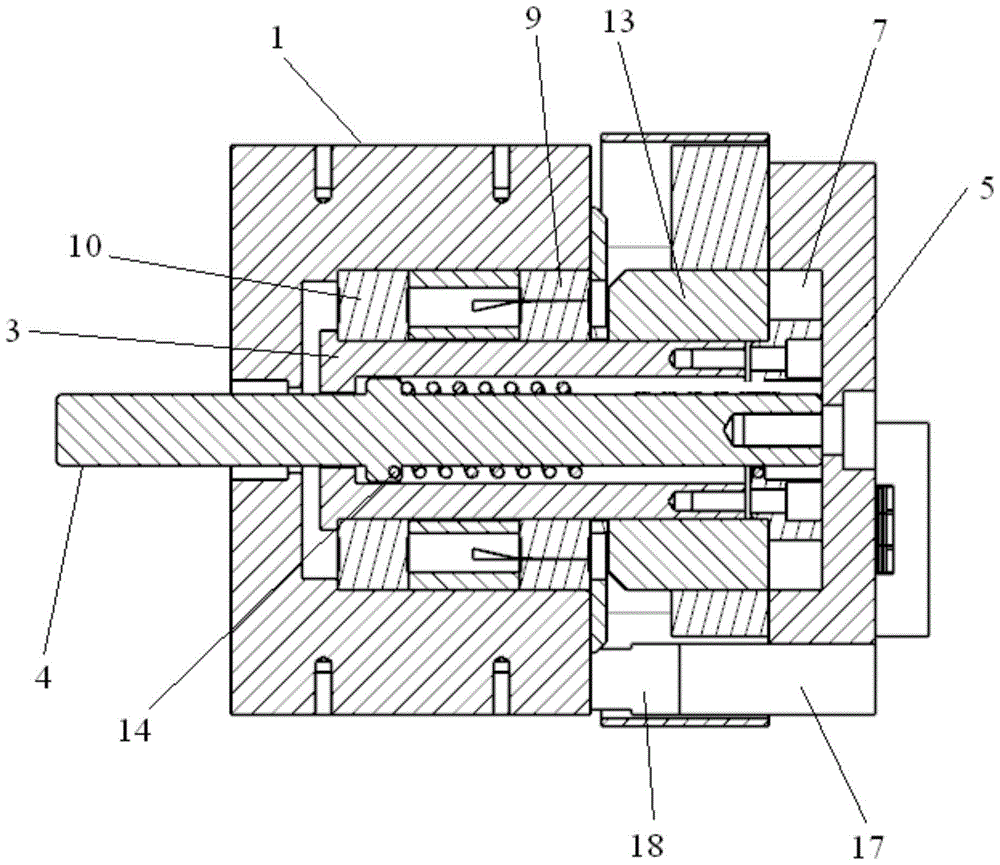

[0030] Mounting base: comprising a fixed seat 2 and a fixed plate 16 arranged on the fixed seat 2, the center of the fixed plate 16 is provided with an internal hollow connecting shaft 6, and the fixed plate 16 is also provided with two first through holes 15, two The first through hole 15 is symmetrically arranged on the fixing plate 16 with the connecting shaft 6 as the center;

[0031] Locking assembly: set on one side of the fixing plate 16, the locking assembly includes a first end cover 5, and the first end cover 5 is provided with a locking pin 7 at a position corresponding to the first through hole 15 on the fixing plate 16 , the lock pin 7 is a tapered lock pin, and the first end cover 5 is also provided with an air supply assembly that promotes the rotation of the polyhedron rotating assembly. The air supply assembly includes an air supply bl...

Embodiment 2

[0036] A polyhedron rotary welding tool shared by multiple car bodies, comprising:

[0037] Mounting base: comprising a fixed seat 2 and a fixed plate 16 arranged on the fixed seat 2, the center of the fixed plate 16 is provided with an internal hollow connecting shaft 6, and the fixed plate 16 is also provided with two first through holes 15, two The first through hole 15 is symmetrically arranged on the fixing plate 16 with the connecting shaft 6 as the center;

[0038] Locking assembly: set on one side of the fixing plate 16, the locking assembly includes a first end cover 5, and the first end cover 5 is provided with a locking pin 7 at a position corresponding to the first through hole 15 on the fixing plate 16 , the lock pin 7 is a tapered lock pin, and the first end cover 5 is also provided with an air supply assembly that promotes the rotation of the polyhedron rotating assembly. The air supply assembly includes an air supply block 17 installed on the first end cover 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com