Reel-to-reel equipment for preparing nano-silver wire electrode film

An electrode film, roll-to-roll technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the constraints on the industrialization, large-scale and batch production of nano-silver electrode films, and the impact on the quality stability of equipment and flexible coating products , Restoration takes a long time and other problems, to achieve the effects of efficient replacement, improved electrical performance, and reduced chance of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, not to limit the present invention.

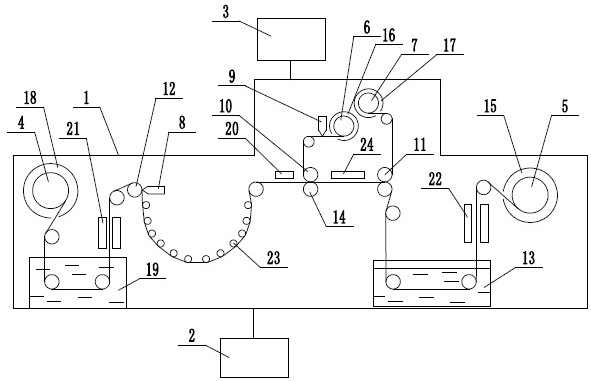

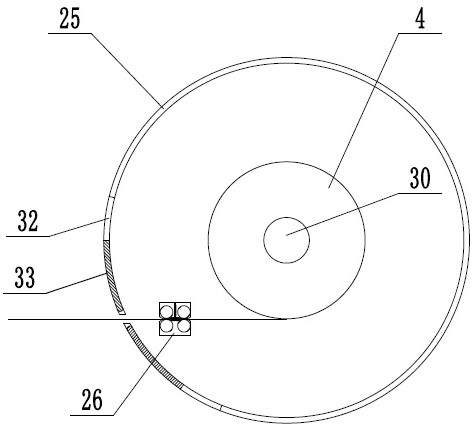

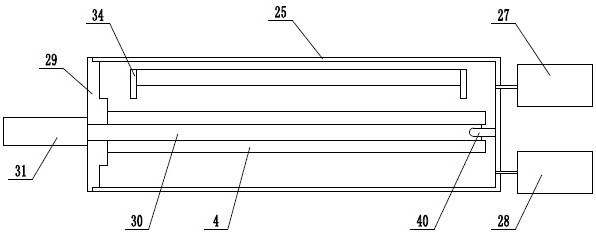

[0049] figure 1 It is a structural schematic diagram of the roll-to-roll equipment for preparing the nano-silver wire electrode film in the present invention. Such as figure 1 As shown, the roll-to-roll equipment for preparing nano-silver wire electrode film of the present invention mainly includes vacuum chamber 1, vacuum system 2, inflation system 3, the first unwinding roll 4, the first winding roll 5, the second unwinding roll 6. The second winding roll 7, nano-silver wire slot die 8, Meyer rod group, polymer slot die 9, embossing roll 10, separation roll 11, coating roll 12 and nano-silver wire recovery pool 13; The first unwinding roller 4, the first winding roller 5, the second unw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com