Vertical type control-releasing fertilizer membrane wrapping fluidized-bed

A fluidized bed, controlled-release fertilizer technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as unsuitable large-scale industrial production, and achieve the effects of high production capacity, low energy consumption, and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

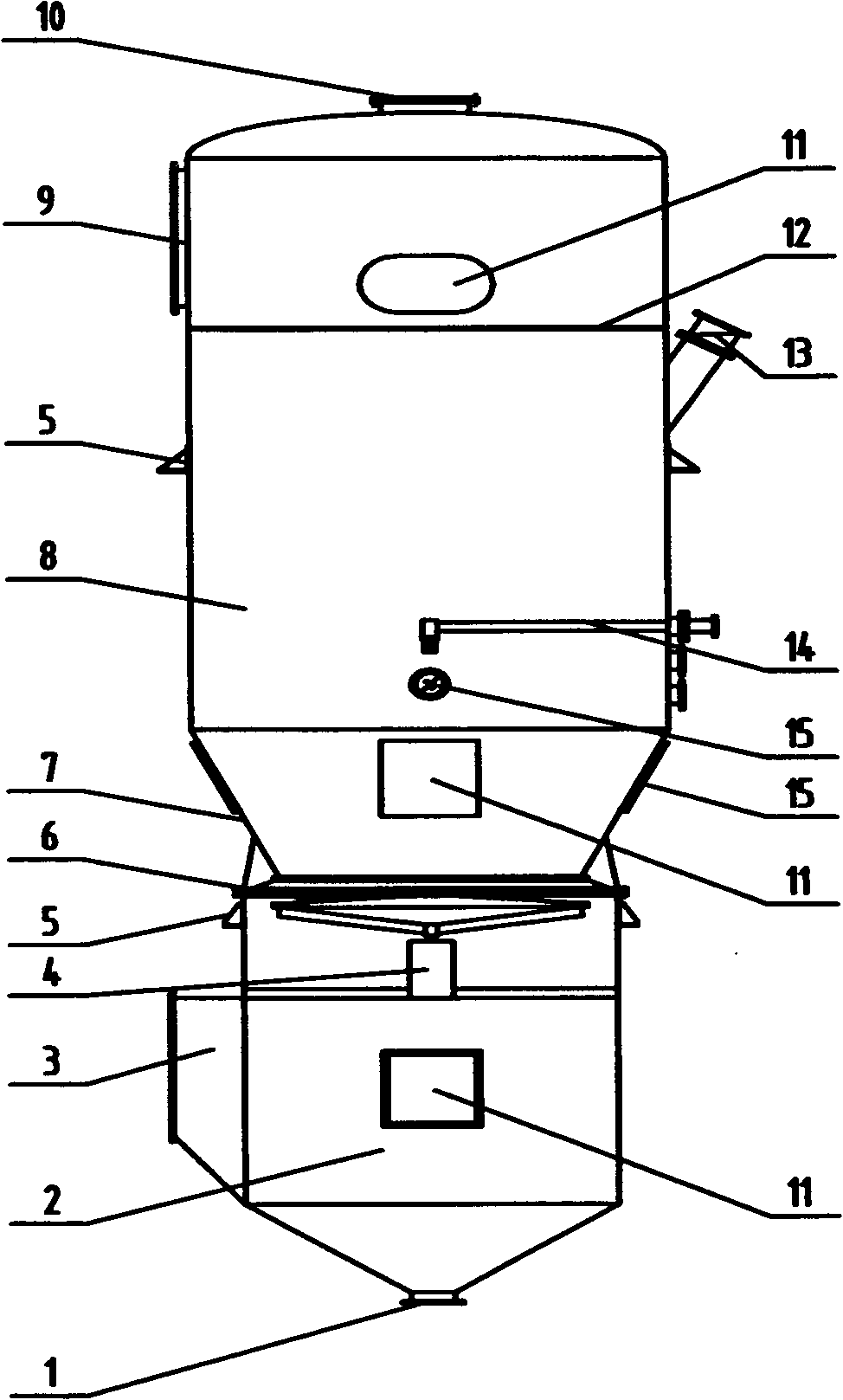

[0020] The structure of a controlled-release fertilizer coated fluidized bed is as follows: figure 1 Shown, but the design of the fluidized bed is not limited to this form. figure 1 The fluidized bed shown includes material outlet automatic control valve 1, bottom discharge bin 2, fluidization gas inlet 3, automatic discharge device 4, air distribution plate 6, middle cone 7, top cylinder 8, fluidization gas Outlet 9, filter screen 12, material inlet automatic control valve 13 and spray gun 14 constitute, the height of described middle cone 7 is 1~3 meters, it connects top cylinder 8 on it, and described top cylinder 8 has a diameter of 2~4 meters. meters, 3-8 meters in height, a filter screen 12 and a spray gun 14 are arranged in the top cylinder 8, the filter screen 12 is located below the fluidization gas outlet 9, and the distance between the spray gun 14 and the air distribution plate 6 is 140-350cm, The middle cone 7 is connected to the bottom unloading bin 2 through th...

Embodiment 2

[0023] Embodiment 2: the vertical controlled-release fertilizer coated fluidized bed as described in Embodiment 1, the difference is that a support 5 is provided on the side wall of the middle cone 7 and the top cylinder 8 for fixing the device.

Embodiment 3

[0024] Embodiment 3: The vertical controlled-release fertilizer coated fluidized bed as described in Embodiment 1, the difference is that an explosion-proof hole 10 is provided at the top of the top cylinder 8 for timely venting of dangerous gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com