Universal fixture in use for supersound cleaning

A technology for ultrasonic cleaning and fixtures, which is applied in the direction of cleaning methods and tools, manufacturing tools, workpiece clamping devices, etc., can solve the problems of pollution, limited number of substrates, and low efficiency, so as to improve the cleaning effect and work efficiency. Use simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

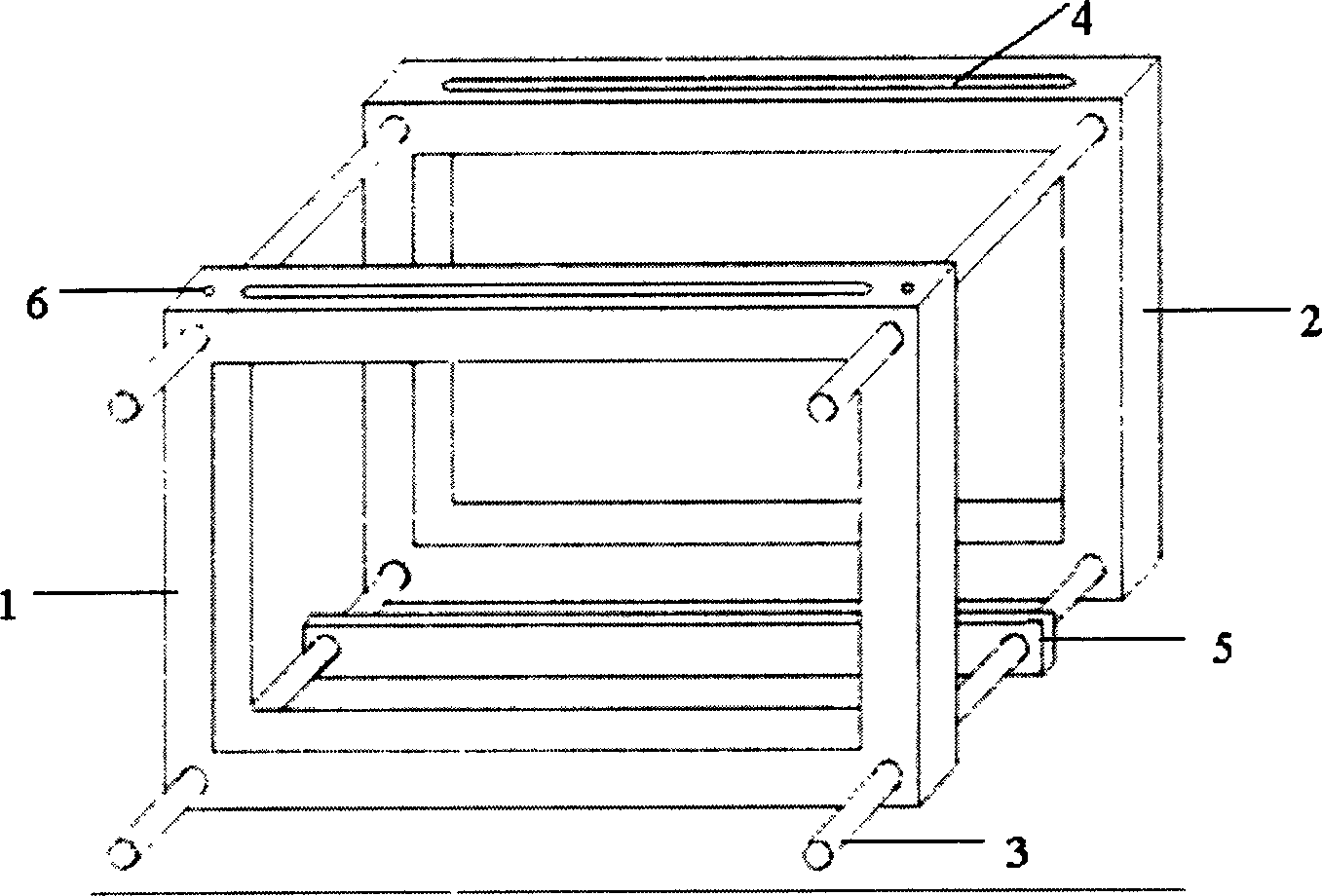

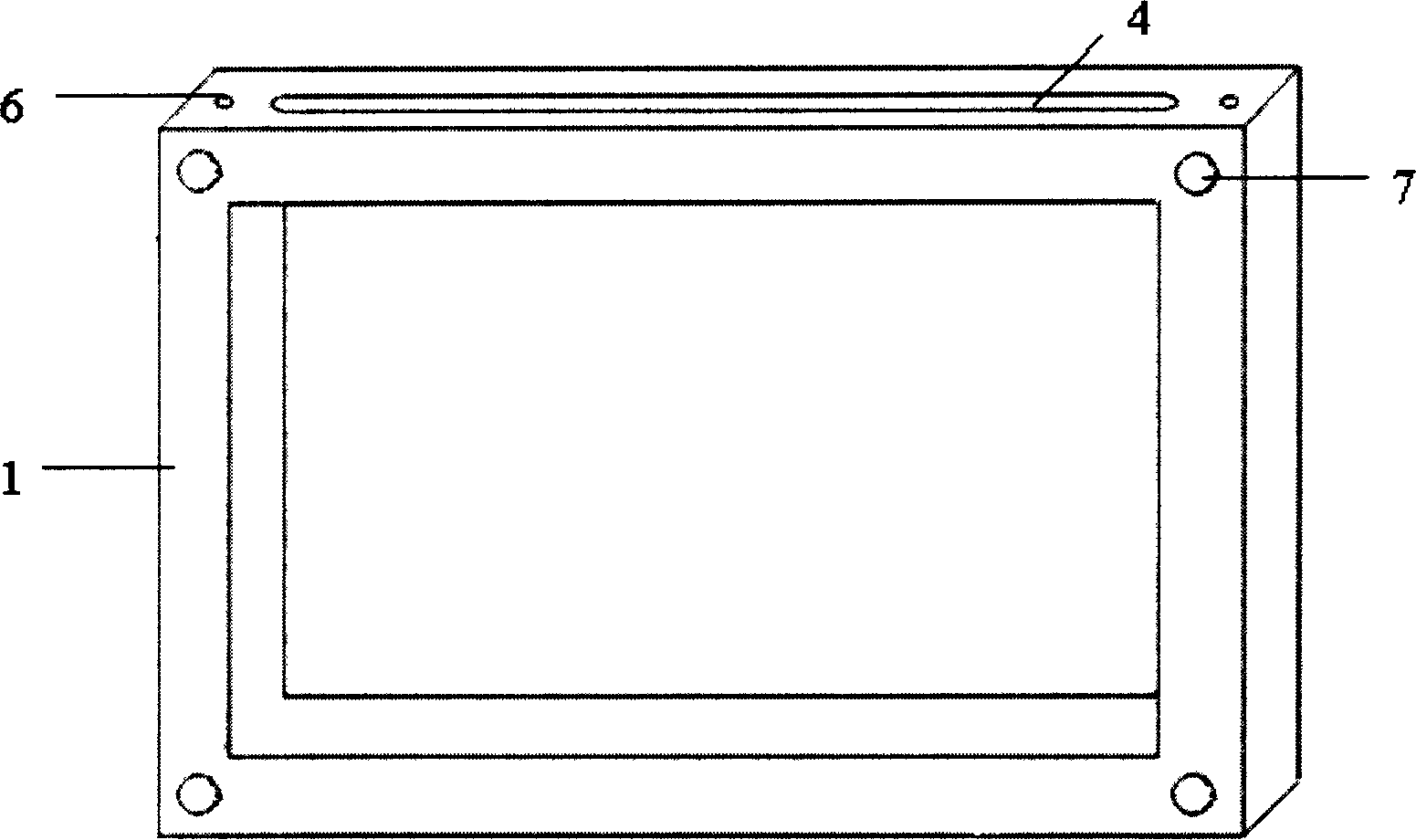

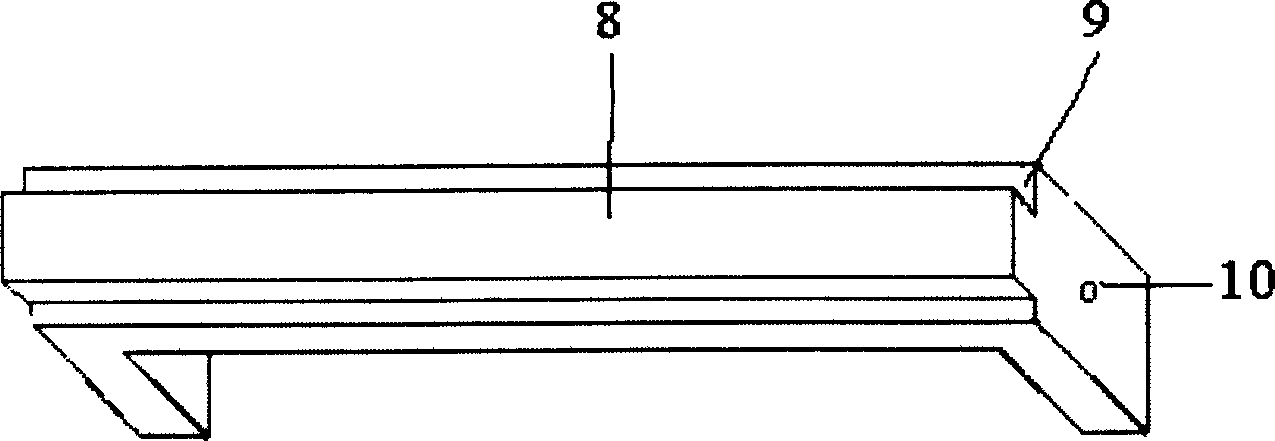

[0019] see first figure 1 , figure 1 It is a structural schematic diagram of one of the embodiments of the ultrasonic cleaning universal fixture of the present invention. It can be seen from the figure that the ultrasonic cleaning universal fixture of the present invention is mainly composed of the following parts: sliding frame 1, fixed frame 2, sliding rod 3, water guide support rod 5 and A certain number of clips 8 are formed. The sliding frame 1 and the fixed frame 2 are rectangular frames with the same size, and round holes 7 are arranged at the same positions of the four corners. The upper and lower outer edges of the two frames 1 and 2 are provided with chute 4, and the upper and lower end surfaces of the sliding frame 1 are connected to each other. For the position of slide bar 3, be provided with four screw holes 6 altogether, the diameter of four cylindrical slide bars 3 is identical with the diameter of the round hole of fixed frame 2 four corners, adopt positive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com