A powertrain anti-torsion tie rod

A technology of powertrain and torsion tie rod, applied in the field of auto parts, can solve the problems of difficult installation of torsion tie rod, affecting normal use, poor installation stability, etc., to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

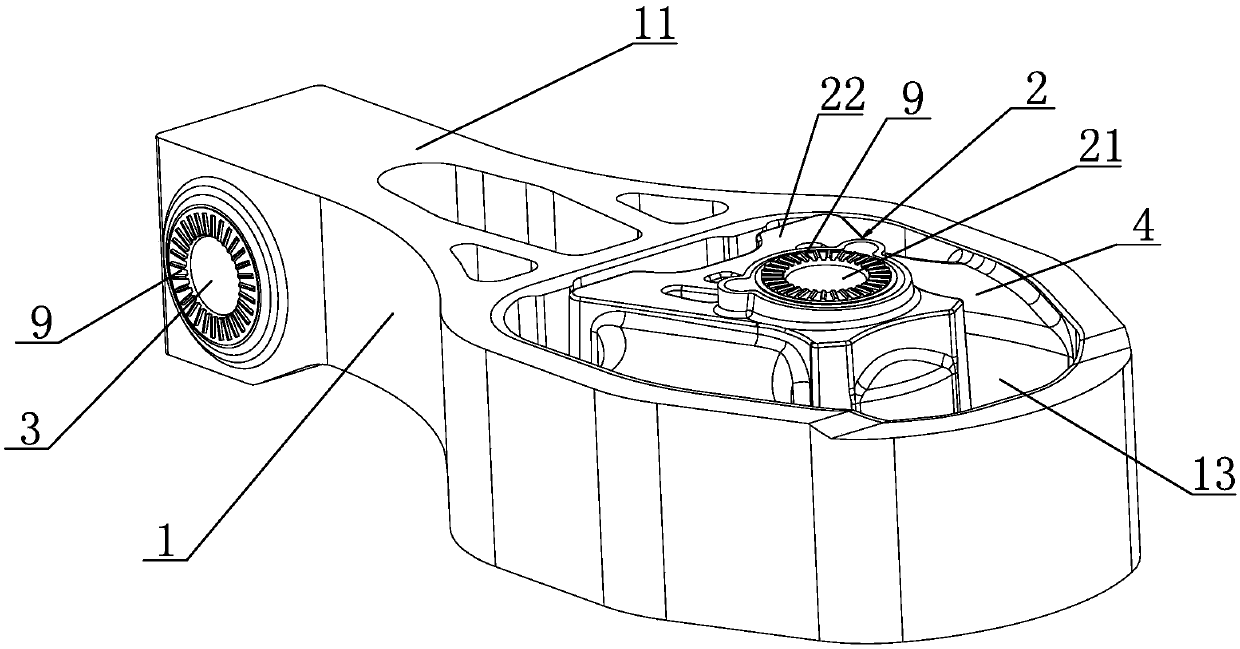

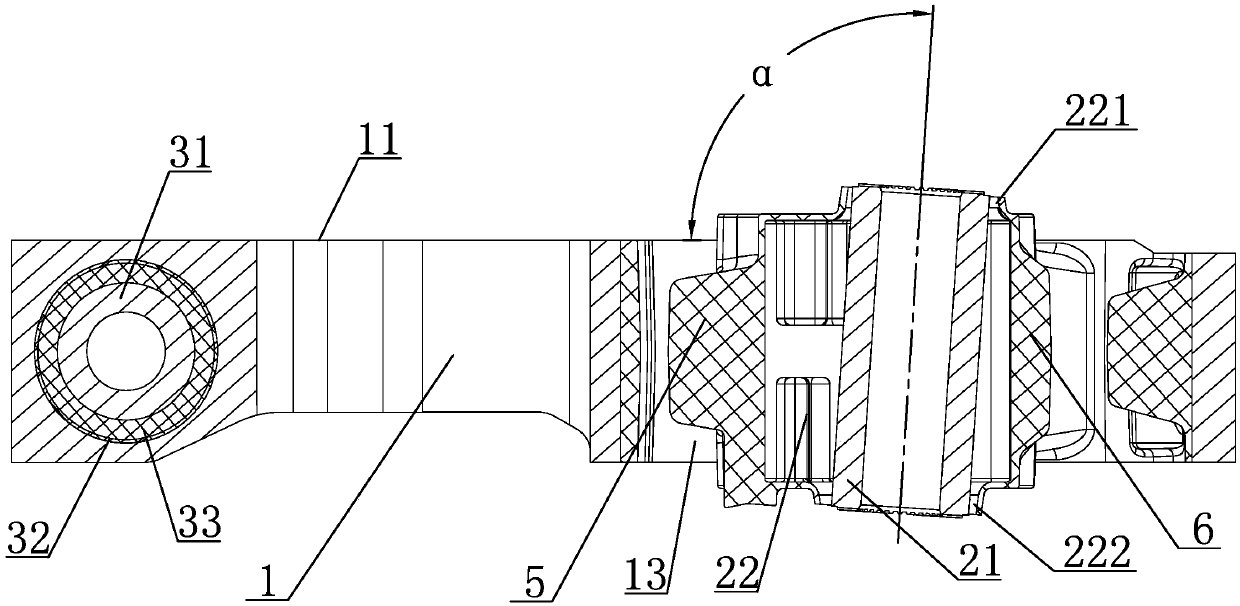

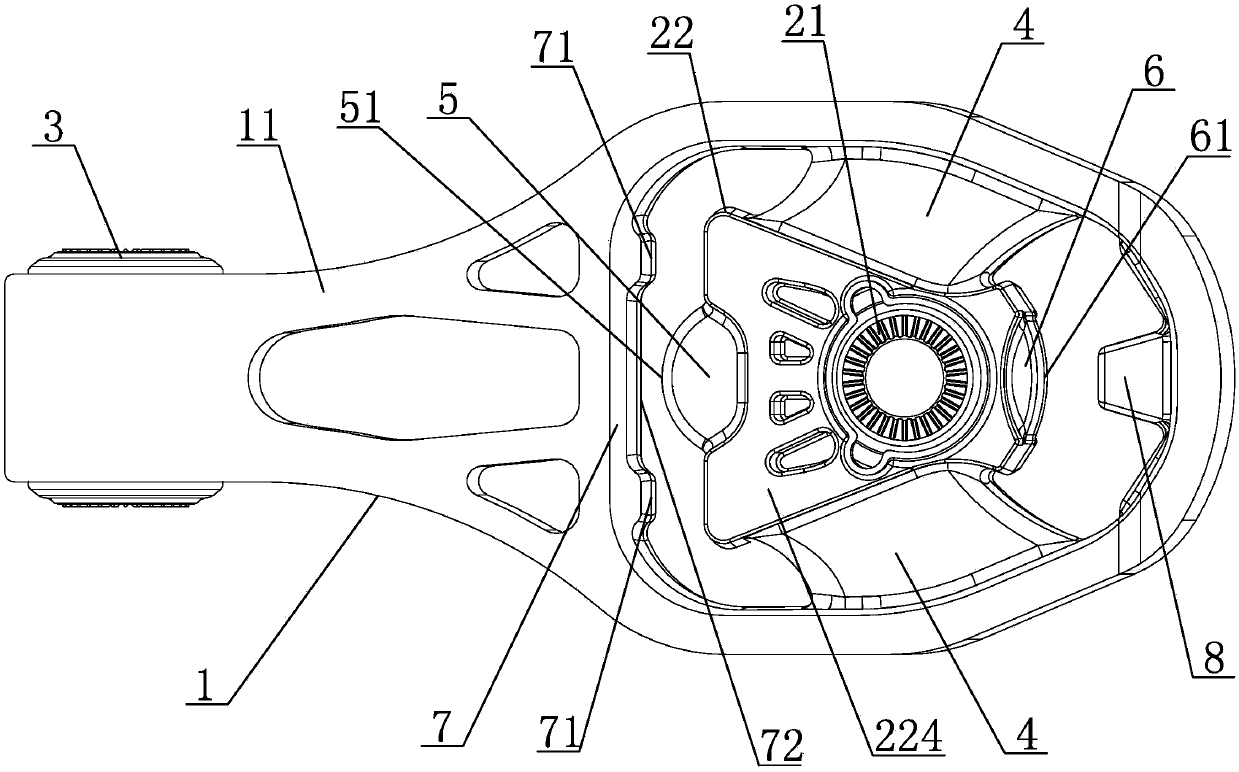

[0025] Embodiment one: if Figure 1 to Figure 6 As shown, a powertrain anti-torsion tie rod includes a tie rod bracket 1 and a large bush 2 and a small bush 3 respectively arranged at both ends of the tie rod bracket 1, the big bush 2 includes a large bush inner tube 21, and the small bush 3 includes a small bushing inner tube 31, the upper surface 11 of the tie rod bracket 1 is a flat end surface, the central axis of the small bushing inner tube 31 is parallel to the upper surface 11 of the tie rod bracket 1, and the central axis of the large bushing inner tube 21 is parallel to the An obtuse angle α is formed between the upper surfaces 11 of the tie rod bracket 1. When one end of the tie rod bracket 1 is connected to the powertrain through a small bush 3, an acute angle β is formed between the upper surface 11 of the tie rod bracket 1 and the horizontal plane. , the difference between obtuse angle α and acute angle β is 90°.

[0026] In this specific embodiment, one end of ...

Embodiment 2

[0036] Embodiment 2: other parts are the same as Embodiment 1, the difference is that the upper surface and the lower surface of the inner tube 21 of the large bush are provided with hobbing teeth 9, and the upper surface and the lower surface of the inner tube 31 of the small bush are provided with There are hobbing 9. Both the upper and lower surfaces of the large bush inner tube 21 and the small bush inner tube 31 are provided with hobbing teeth 9, which can effectively improve the friction coefficient between the parts and the installation interface, making the installation more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com